Description

Real-World Use & Application Scenarios

In industries where functional safety and reliable data communication are imperative, the HIMA F8627X communication module plays a critical role. It is widely employed in oil and gas, chemical processing, power generation, and other sectors demanding high-integrity safety instrumented systems (SIS). This module facilitates the exchange of safety-critical data within HIMA’s HIQuad X and HIMax safety systems, enabling secure, real-time control of emergency shutdowns, safety interlocks, and process monitoring.

Its robust design ensures dependable performance in harsh industrial environments characterized by extreme temperatures, humidity, and electromagnetic interference. The F8627X integrates into safety networks where rapid and accurate data transfer is crucial for protecting personnel, assets, and the environment from potentially hazardous situations.

Product Introduction & Positioning

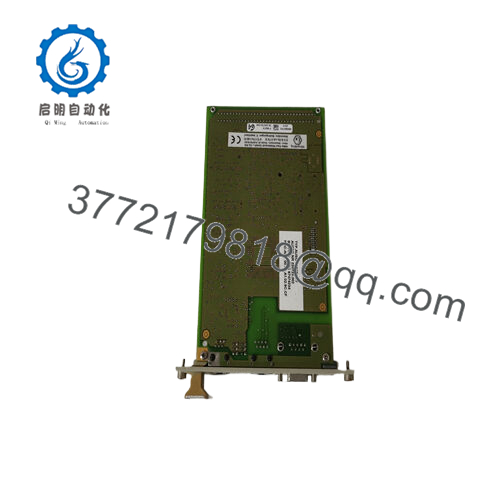

The HIMA F8627X is a high-performance Ethernet and PROFIBUS communication module for HIMA programmable safety controllers, including the F8650X and F8652X secure CPUs, as well as the F8651X and F8653X non-secure CPUs. It serves as a communication interface enabling programming via ELOP II software and supporting standard industrial protocols such as Modbus TCP/IP, Profibus DP slave, and OPC.

Designed as a rack-mounted module compatible with the 19-inch HIMA controller systems, the F8627X is pivotal in connecting safety CPUs to engineering workstations and plant networks. It provides flexible communication pathways that enhance system scalability, diagnostics, and integration with broader plant control architectures.

System integrators and safety engineers appreciate this module for its ease of use, protocol versatility, and compliance with functional safety requirements according to IEC 61508 and IEC 61511 standards.

Key Technical Features & Functional Benefits

The HIMA F8627X supports data transfer rates up to 1 Mbps for Profibus DP and higher speeds for Ethernet (fast Ethernet 10/100 Mbps), enabling high-speed communication necessary for timely safety responses. It features dual RJ-45 Ethernet connectors with integrated LEDs for simplified network connectivity and status monitoring.

It operates reliably over a wide industrial temperature range (-40°C to +85°C) and resists harsh environmental conditions with robust electrical isolation and noise immunity. The module supports ELOP II programming via Ethernet from version 4.1 onward, streamlining engineering and configuration workflows.

Weighing approximately 0.8 kg and sized at 16 cm × 16 cm × 12 cm, the module fits well within standard racks without demanding excessive space or cooling. Its use of an ARM Cortex processor ensures rapid processing and multitasking capabilities essential for complex safety protocols.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | HIMA F8627X |

| Brand | HIMA |

| Product Type | Communication Module |

| Supported Protocols | Ethernet (Fast Ethernet 10/100 Mbps), Profibus DP Slave, Modbus TCP/IP, OPC |

| Communication Speed | Up to 1 Mbps (Profibus DP), 10/100 Mbps Ethernet |

| Input Power | 24 V DC |

| Operating Temperature Range | -40°C to +85°C |

| Dimensions | 16 cm x 16 cm x 12 cm |

| Weight | 0.8 kg |

| Connectivity | Dual RJ-45 Ethernet Ports with Status LEDs |

| Processor | ARM Cortex |

| Certifications | IEC 61508, IEC 61511 |

Related Modules or Compatible Units

HIMA F8650X CPU – Secure CPU for HIQuad X safety system.

HIMA F8651X CPU – Non-secure CPU variant for HIQuad X system.

HIMA F8628X Communication Module – Communication companion module supporting Profibus and Ethernet.

HIMA F7130A Power Supply Module – Provides isolated power to system modules.

HIMA F3236 Digital Input Module – Safety digital input acquisition module.

HIMA F3330 Relay Output Module – Safety-related digital output module.

- F8627X

- F8627X

Installation Notes & Maintenance Best Practices

Installation calls for secure mounting within HIMA standard racks with proper wiring to 24 V DC power supply and Ethernet or Profibus network connections. Shielded Ethernet cables and compliance with EMC guidelines ensure stable communication.

Maintenance involves monitoring LED status indicators for network integrity, regular firmware upgrades via ELOP II software, and periodic verification of physical cabling and connectors. Diagnostic features within the module assist in proactive troubleshooting and minimizing unscheduled downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626