Description

In the safety-critical nexus of industrial automation, where seamless data exchange between redundant safety controllers and supervisory systems is paramount to averting process upsets or fault propagations in real-time loops, engineers often contend with the rigidity of legacy serial interfaces that bottleneck Ethernet migrations or expose systems to single points of failure. Picture a safety instrumented function in a chemical reactor or a burner interlock in a furnace train: CPUs like the H51q or H41q process voted inputs from field devices, but routing them to OPC servers, Profibus overlays, or programming tools demands protocol agility, lest incompatible modules spawn latency, diagnostic gaps, or non-compliance in SIL 3 architectures governed by IEC 61508. This connectivity conundrum not only fragments process control but escalates exposures in high-reliability deployments, where a stalled Ethernet link could delay a shutdown signal, transforming a minor overpressure into a major mitigation mishap with cascading consequences for uptime and audits.

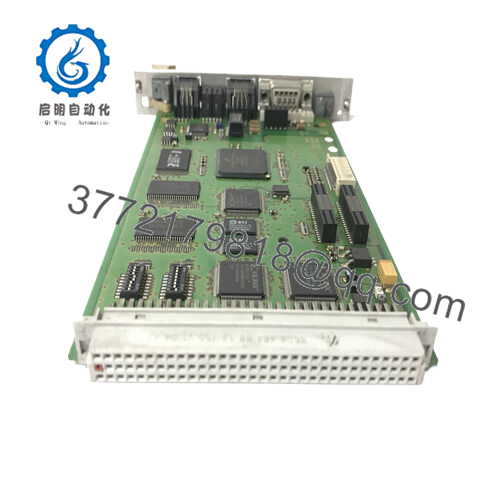

The HIMA F8627 984862702 stands as the versatile communication module for HIMA’s H41q and H51q safety systems, resolving these integration hurdles by enabling safe, high-speed Ethernet-based protocols including SafeEthernet for redundant inter-system links, OPC DA/A&E via HIMA OPC server, Modbus-TCP slave mode, and ELOP II programming directly over Ethernet. It becomes indispensable in environments demanding fault-tolerant networking, such as distributed ESD networks in oil and gas platforms or PLC hybrids in power generation, where mono or redundant configurations ensure data flows uninterrupted amid EMI or cable faults. From safety PLC audits I’ve guided in distillation columns, teams frequently tangle with serial-bound modules that necessitate protocol converters or fiber extenders, inflating engineering hours and validation vectors that undermine scalability. The HIMA F8627 984862702 flips this by supporting 100Base-T interfaces with RJ45 connectivity, allowing seamless CPU programming and OPC data pulls without downtime, so you prioritize logic layering over link logistics. In the protocol-plaited panorama of industrial automation, it embodies the bridge to broadband safety, where high-reliability I/O signals traverse Ethernet with the determinism that defines distributed diagnostics, turning potential silos into synchronized safeguards that honor CENELEC SIL 4 envelopes.

By fusing legacy compatibility with modern Ethernet ethos into a rack-mountable form, the HIMA F8627 984862702 facilitates expansions from standalone nodes to ring topologies, nurturing the network neutrality that anticipates evolutions in safety paradigms. It’s the comms catalyst calibrated for those convergence-crucial corridors in process control, where a packet’s passage preserves parity, delivering the protocol prowess that propels protections and preempts pitfalls.

When weaving the HIMA F8627 984862702 into an H51q or H41q rack for enhanced interlock interplay, it acts as the Ethernet enabler at the protocol periphery, plugging into the backplane to interface with secure CPUs like the F8650X/F8652X (for H51q) or F8651X/F8653X (for H41q), channeling data streams over 100Base-T SafeEthernet for redundant mono or duplex links up to 100 Mbps, while exposing OPC DA/A&E endpoints via the HIMA OPC server for SCADA fusion and Modbus-TCP slave registers for PLC queries. It occupies a 3-height unit (3HE) slot in a 19-inch subrack, drawing 24 VDC from system rails and terminating via RJ45 for star or daisy-chained topologies, situating it mid-stack between CPU logic and field gateways where it buffers SafeEthernet packets against faults, ensuring voted outputs reach Profibus DP slaves or ELOP II tools without propagation pauses.

- F8627 984862702

- F8627 984862702

In flow, it dialogues via SILworX for configuration—mapping registers for custom OPC tags or enabling ELOP II V4.1+ programming over TCP—while diagnostics embed at the link layer, monitoring CRC errors or link drops through system LEDs and Modbus alerts to HMIs, so you reroute redundantly on fiber converters without full-system scans. It supports hot-plug insertion for maintenance swaps, with galvanic isolation to 1.5 kV thwarting surges from adjacent power modules, and no external hubs required; it multiplexes protocols natively, facilitating OPC alarms for event propagation or SafeEthernet rings for SIL 4 loops in large-scale ESDs. For a typical safety island, it pairs upstream with power supplies and downstream with I/O terminators, forming a resilient bus that scales to 512 nodes without bandwidth bottlenecks.

This interoperability thrives in hybrid hierarchies, where it complements legacy F8628 Profibus modules for mixed-protocol bays or extends via fiber for kilometer-spanning plants, its ELOP II Ethernet mode slashing programming cycles from serial tethers. For migrations, it coexists with older F8627 variants, preserving wiring while upgrading to OPC A&E for predictive analytics. This isn’t mere mediation; the HIMA F8627 984862702 manifests messaging mastery, interlacing safety semantics into a process control continuum that conveys coherently, anticipating the accords that affirm asset assurance.

| Specification | Details |

|---|---|

| Model Number | F8627 984862702 |

| Brand | HIMA |

| Type | Communication Module |

| Input Voltage | 24 V DC |

| Operating Temp Range | -15°C to +60°C |

| Mounting Style | 19-inch Subrack (3HE) |

| Dimensions | 221 x 133 x 100 mm |

| Weight | 0.6 kg |

| Interface/Bus | 100Base-T Ethernet (RJ45) |

| Compliance | IEC 61508 SIL 3, CENELEC SIL 4 |

| Supported Protocols | SafeEthernet, OPC DA/A&E, Modbus-TCP, ELOP II Ethernet |

| Typical Power Draw | 5 W |

Selecting the HIMA F8627 984862702 equips your safety fabric with a flux of federated fluency that fortifies fault foresight, where SafeEthernet redundancy elevates event echoes to enterprise echoes—envision streaming a voted interlock to an OPC client during a transient, compressing confirmation cycles from seconds to sub-second and circumventing the serial scans that stall SCADA shifts. Forged for the protocol pulses of plant peripheries, it fastens flawless forwarding through CRC-checked channels and link resilience, so query queues or cable cuts don’t lacerate loads, yielding the disseminated depth that drives decision dashboards and defers diagnostic downtime without datastream detours.

This module also galvanizes governance graces, its OPC-embedded diagnostics and register stats streamlining sync sweeps to surgical sends over sprawling searches—pivotal in plants where protocol proofs press against production paces and parity pacts prevail. Within rack realms, it lightens linkage loads by leveraging Ethernet ethos, so system suites swell sans serial skirmishes or map machinations, marshaling momentum to multifaceted melds like IIoT infusions. Overseers obtain osmotic osmosis from its status streams, where packet pedigrees provide proactive pulses, propagating paradigms that perceive payloads as portents, not puzzles.

Deeper, the HIMA F8627 984862702 gestates gateway grandeur, its 100 Mbps unyieldingness undercutting upload upsets to uplift MTBF, while versatile vectors—SafeEthernet to Modbus—vest in varied ventures sans variant vexes. The transmissions transmute: tempered telemetries that transmute turnarounds, ledger-lucid ledgers for levy lulls, and the ken to knit networked narratives for networked narratives, all netted in a module that doesn’t dally data, but dispatches it into your automation’s discursive dominion.

In petrochemical ESD networks, the HIMA F8627 984862702 ferries CPU commands amid hydrocarbon hazes, enduring enclosure eddies to disseminate critical system uptime via OPC polls on pressures—indispensable for process control environments where register rifts could rupture risers and raze recoveries. Its SafeEthernet sovereignty sustains sync under surge scenarios, upholding high reliability in nodes navigating natgas networks.

For power generation turbine safeguards, it’s subracked to relay relay recitals through gridline gusts, prevailing against panel pulses for continuous uptime, with ELOP II Ethernet eliciting ESD echoes on escalations. The HIMA F8627 984862702 bolsters modular integration, broadening bridges buoyantly for baseload builds without beacon bifurcations.

In rail signaling interlocks, the HIMA F8627 984862702 profiles point protocols in trackside towers, reinforcing fast data cycles for fault forwards in flow fluxes—harnessed in process control environments hewing to CENELEC SIL 4 to hinder house harms and husband hearth hauls.

F8627X – Enhanced Ethernet variant with OPC A&E and Modbus-TCP slave for advanced OPC integrations.

F8628 – Profibus DP slave companion for legacy fieldbus ties in mixed-protocol bays.

F8628X – Updated Profibus module with ELOP II Ethernet programming for hybrid upgrades.

F8650X – Secure CPU host for the F8627 984862702 in H51q SIL 3 systems.

F8652X – Redundant secure CPU for fault-tolerant pairing with the F8627 984862702.

F8651X – Non-secure CPU alternative for cost-optimized H41q deployments.

F8653X – High-performance non-secure CPU for scaling with the F8627 984862702.

Before subracking the HIMA F8627 984862702, confirm CPU compatibility—H51q needs F8650X/F8652X secure variants, and RJ45 terminators tune for daisy chains to dodge reflections; align firmware via ELOP II offline sims to preempt protocol lags. Torque backplane connectors to 0.6 Nm, then cycle power—steady green on link confirms quorum, but partials prompt reseats. Network neutrality: ensure 100mm clearance for convection in dusty domains, and bond chassis per EMC to quell induced packets from nearby actuators.

In service, quarterly quartz quests at RJ45 junctions quell contact corrosion, chiefly in humid hazards—depower domains, ohm to ground, and docket deltas past 100 Ohm. Monthly, mine diagnostic dumps for CRC drifts that foreshadow overloads, cross-checking against event logs; amber alerts linger? Isolate links via software for granular gates. Annual full-rack tests during halts—simulating faults across protocols—validate redundancy without field frights, while ELOP II syncs coincide with safety-wide updates, backed by config caches. These comms canons, culled from connectivity chronicles, conserve the module’s mettle, curbing the covert creeps that clog channel currents.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626