Description

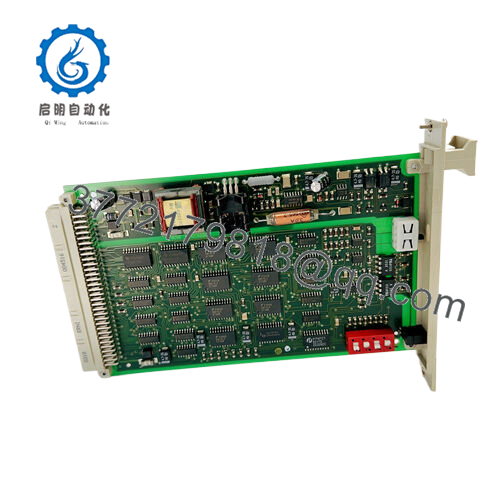

HIMA F7553 984755302 is a safety controller module in the well-known HIMA F7000 series, which is the gold standard for safety critical automation. As part of the HIMA ELOP II platform, it serves as the computational core of the safety instrumented system, executing logic solver functions with deterministic accuracy. Unlike standard controllers, this module is designed specifically for safety applications, combining hardware redundancy, self diagnostic capabilities, and compliance with SIL 3 (Safety Integrity Level 3) standard certification.

F7553 984755302

Its role in the system architecture is to process inputs from sensors (such as pressure transmitters, emergency stop buttons), compare them with pre programmed safety logic, and issue commands to actuators (such as shut-off valves, motor starters) to force them into a safe state. F7553 984755302 can seamlessly integrate with HIMA’s engineering tools (such as HIMA Engineer Suite) to achieve intuitive configuration of safety functions and diagnostic monitoring.

F7553 984755302

Main features and advantages:

It supports hot swappable functionality and can be maintained without interrupting factory operations – a key feature for reducing downtime for facilities that require 24/7 continuous operation. Its compact design also simplifies the retrofitting of existing systems, making it a flexible upgrade option for modern and secure infrastructure.

HIMA F7553 984755302 provides excellent performance through its dual core processor and lockstep technology, ensuring that both cores execute the same code simultaneously and compare results to detect errors. This design achieves a diagnostic coverage rate of over 99%, far exceeding the industry standard for safety critical systems. The processing speed of this module – capable of executing up to 100000 logical steps per millisecond – ensures rapid response to hazards in high-speed process environments such as gas turbine control.

In terms of hardware, this module is sturdy and durable. It can operate at operating temperatures ranging from -40 ° C to+70 ° C and complies with shock and vibration standards (such as IEC 61326-3-2), making it suitable for offshore platforms, mining sites, and other harsh environments. Its DIN rail installation and modular design facilitate installation and expansion, while the built-in surge protection prevents power fluctuations and transient overvoltages.

Compatibility is the core advantage of this module: F7553 984755302 supports multiple communication protocols, including PROFIBUS DP, Ethernet/IP, and Modbus TCP, and can seamlessly integrate with PLC, HMI, and SCADA systems from different suppliers. This interoperability reduces the need for customized interfaces, simplifies system design, and lowers integration costs.

From a long-term feasibility perspective, this module has a self-monitoring architecture that can continuously test its own hardware and software integrity. Combined with a 10-year lifecycle guarantee, this ensures that the security system remains certified and operational throughout its entire design life, reducing the risk of obsolescence in critical infrastructure.

F7553 984755302

Technical specifications:

Model HIMA F7553 984755302

Brand HIMA

Type safety controller module (SIL 3 certified)

Power supply 24V DC ± 20%

Working temperature -40 ° C to+70 ° C

Installation method DIN rail (TS 35/7.5 or TS 35/15)

Dimensions: 120mm (width) x 160mm (height) x 100mm (depth)

Weight 0.8 kg

Interface PROFIBUS DP, Ethernet/IP, Modbus TCP, USB (for programming)

Certified IEC 61508 (SIL 3), IEC 61511 (SIS), ATEX, CSA, FM, DNV GL

Heat dissipation method: Thermal conduction (passive, fanless)

Environmental protection level IP20 (indoor use), compliant with EMI/EMC standards of EN 61000-6-2/-6-3

Contact Us

Phone:+86 16626708626

WhatsApp/WeChat:+86 16626708626

Email: 3772179818@qq.com

F7553 984755302

Application areas:

In petrochemical plants, HIMAF7553 984755302 is used to monitor pressure, temperature, and flow in reactors and pipelines. If a parameter deviation from the safe range is detected (such as a sudden increase in pressure), it will immediately trigger a shutdown procedure or safety interlock device to isolate the danger.

In the field of power generation, it ensures the safe operation of steam turbines by managing emergency shutdown protocols and fault detection in complex power grid systems. For facilities that need to comply with international safety standards such as IEC 61508 and IEC 61511, this module plays a crucial role in industrial automation as these standards require system integrity to be legally binding.

Related products:

HIMA F3321- Safety Digital Input Module (24 V DC, 16 channels), used to connect sensors and switches to the F7553 safety network.

HIMA F3231- Safety Analog Output Module (4-20 mA), used in conjunction with F7553 to control actuators such as valves and drivers.

HIMA F8650- Ethernet communication module, used to integrate F7553 with higher-level SCADA systems or cloud based monitoring platforms.

HIMA F3721- Relay Output Module (250 V AC/30 V DC), used for fault-tolerant switching in low-power applications, compatible with the logic solver of F7553.

HIMA F7122- Backup Battery Module, designed to ensure uninterrupted operation during power outages, is ideal for maintaining the functionality of F7553 in emergency situations.

HIMA F3403- Temperature Input Module (RTD/Thermocouple), used for direct integration with process temperature sensors to expand the monitoring capabilities of F7553.

HIMA F9650- Gateway module, used to connect F7553 to legacy systems through protocols such as Modbus RTU or PROFINET, for retrofitting in hybrid environments.

Installation and maintenance:

Before installing HIMAF7553 984755302, please ensure that the control cabinet provides sufficient heat dissipation clearance (minimum 25 mm between modules) to prevent overheating during high-density installation. Grounding is crucial: Use a dedicated grounding connection with a grounding resistance of ≤ 4 Ω to comply with EMC standards and prevent voltage spikes. Engineers should also verify whether the EMI shielding of the cabinet meets the environmental requirements of the module, especially in facilities with heavy machinery or high-frequency equipment.

For maintenance, it is recommended to conduct a visual inspection every quarter to check for loose connections, corrosion, or physical damage to the module terminals. It is crucial to conduct monthly diagnostic reviews through HIMA’s engineering tools to monitor self inspection results and identify early signs of component degradation (such as internal temperature rise). Firmware updates should be performed annually or as recommended by HIMA, using safety procedures to avoid introducing errors during the update process. The built-in diagnostic function of the module should be regularly used to test the safety circuit to ensure that the logic solver function and communication path are fully functioning properly.

HIMA Other Product Models:

HIMA PS1000WR011

HIMA F3DIO20/802 982200484

Hima F8621A

HIMA F8627X 984862765

HIMA 80105 984080105

HIMA ELOP II V5.5

HIMA 80105 984080105

HIMA X-SB01 985210207

HIMA F8628X

HIMA F8650X 984865065

HIMA A1-dig 984200004

HIMA X-AI3201 985210213

HIMA TRIX F35 982200416

HIMA F3DIO20/802 982200442

HIMA F8650E

HIMA F3226A

HIMA F8621A 984862160

HIMA F-PWR01

HIMA F3DIO16/801

HIMA Z7130

HIMA F3240

HIMA F30 03 SILworX 20/9

HIMA F3237

HIMA F8651X

HIMA F3DIO20/802 982200404

HiMA F35 030 34 SILworX

HIMA F-COM01

HIMA F-IOP01

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

HIMA F30 F30 010 20 OS-REV.V6.46/V11.28

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626