Description

Real-World Use & Application Scenarios

In safety-critical automation environments such as oil and gas, power generation, and chemical manufacturing, the availability of stable and reliable power to safety instrumented systems is crucial. The HIMA F7126 power supply module ensures continuous and isolated DC power to essential safety control and I/O modules, supporting safe and uninterrupted plant operation.

This module is widely used in industrial safety control systems where it powers programmable electronic safety systems including HIMA HIQuad and HIMax platforms. Its design mitigates power faults and interruptions that can otherwise compromise safety functions and lead to costly shutdowns or hazardous incidents.

By delivering stable, regulated power, the F7126 helps maintain system integrity and compliance with tight safety standards, enabling industries to mitigate risks in demanding processing environments.

Product Introduction & Positioning

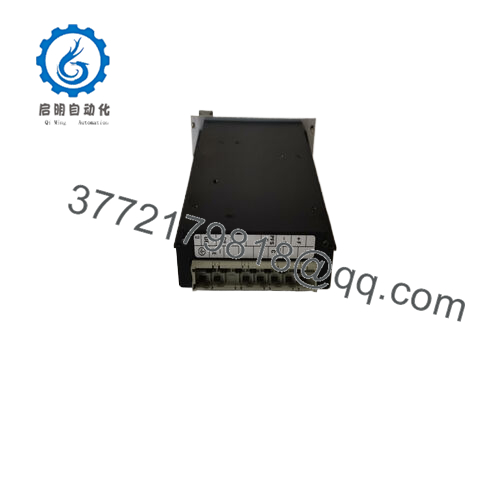

The HIMA F7126 is a dedicated power supply module designed for safety instrumented systems, converting a 24 V DC input into a regulated 5 V DC output with isolation. It provides power specifically for central processing units and rear I/O modules in modular safety control racks.

This module fits standard HIMA safety controller chassis, maintaining system modularity and allowing easy expansion or replacement. Its overvoltage, short-circuit protection, and current limitation features ensure that connected safety devices receive consistent, clean power without risk of damage.

The F7126 is integral to implementing reliable functional safety, valued by system designers and safety experts for its robust performance and compliance with IEC 61508 and IEC 61511 standards.

- F7126

- F7126

Key Technical Features & Functional Benefits

The HIMA F7126 provides a regulated 5 V DC output at up to 10 A, with factory-adjustable voltage up to ±0.5 V. It incorporates a primary fuse rated at 6.3 A and includes overvoltage protection set at approximately 5.4 V ± 0.025 V, safeguarding connected safety modules.

Power-efficient with an efficiency of ≥ 77%, the module minimizes heat generation in compact control cabinets. Designed for industrial conditions, it operates reliably from -40°C to +70°C and supports redundant power supplies with load balancing requiring output voltage differences within 0.025 V.

Its front panel features a test socket and potentiometer for easy voltage adjustment and diagnostics, supporting quick validation and maintenance activities.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | HIMA F7126 |

| Brand | HIMA |

| Product Type | Power Supply Module |

| Input Voltage | 24 V DC ± 15% |

| Output Voltage | 5 V DC ± 0.5 V (adjustable) |

| Output Current | 10 A (current limit ~13 A) |

| Primary Fuse | 6.3 A |

| Overvoltage Protection | 5.4 V DC ± 0.025 V |

| Efficiency | ≥ 77% |

| Operating Temperature | -40°C to +70°C |

| Dimensions | Approx. 21 cm x 13 cm x 3 cm |

| Weight | Approx. 0.2 kg |

| Mounting | Standard Rack Mount (8 TE) |

| Additional Features | Test socket, potentiometer, load balancing for redundancy |

Related Modules or Compatible Units

HIMA F7130A Power Supply Module – Complements power requirements with an alternative power supply.

HIMA F8628X Communication Module – Communication interface for safety system networking.

HIMA F3221 Digital Input Module – Controls and monitors multiple discrete input signals.

HIMA F3330 Digital Output Module – Provides relay outputs for safety signaling.

HIMA F8650X CPU Module – Central processing unit for safety logic execution.

HIMA F3236 Digital Input Module – Supports industrial safety input acquisition.

Installation Notes & Maintenance Best Practices

Ensure the F7126 is installed in a rack environment with adequate ventilation to maintain optimum operating temperature. Proper wiring according to manufacturer guidelines is critical, ensuring secure connections for input and output voltage lines.

Conduct routine visual inspections for signs of wear or damage and verify output voltage levels with the built-in test socket and potentiometer. Firmware or software updates for related safety control systems should be applied regularly to ensure compatibility and optimized performance.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626