Description

In the safety-vital vein of industrial automation, where analog signals from field transmitters—such as pressure differentials or level gauges—must be acquired with unerring accuracy to inform control decisions and avert hazardous excursions, engineers often face the pitfalls of non-isolated inputs that amplify noise or fail under fault loads, leading to skewed process variables or undetected drifts. Envision a distillation column in a refinery or a pressure relief loop in a gas compressor station: 4-20 mA loops from Rosemount or Yokogawa sensors feed into logic solvers, but conventional modules expose systems to ground loops, EMI ingress, or resolution shortfalls, risking SIL 3 non-conformance under IEC 61508 and spawning validation overhauls that idle units for days. This acquisition Achilles’ heel not only destabilizes process control but magnifies menaces in high-reliability SIS, where a 2% signal skew could bypass a high-high interlock, escalating from overfill alerts to overpressure events with multimillion-dollar repercussions.

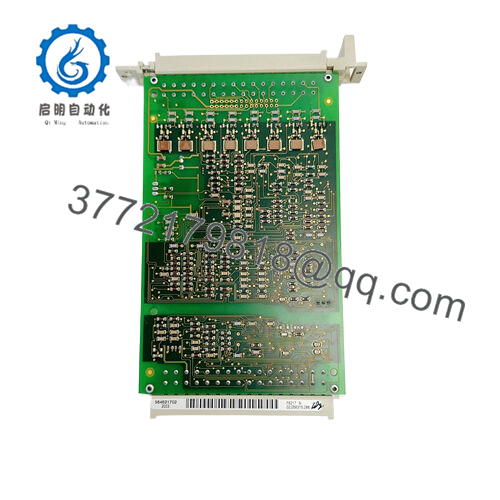

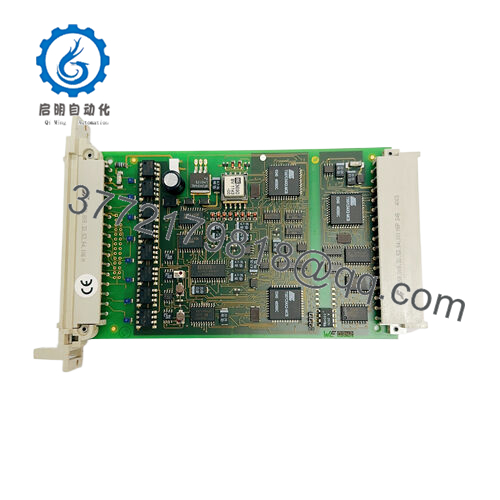

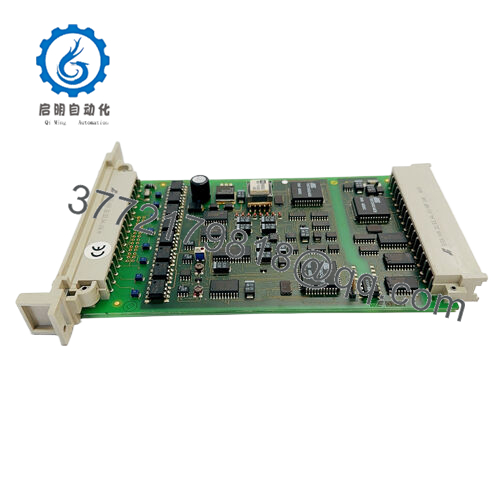

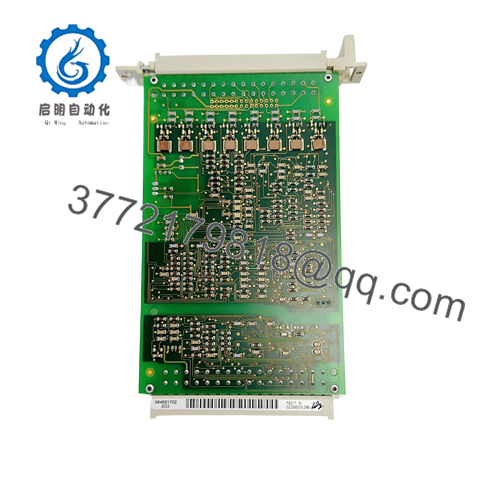

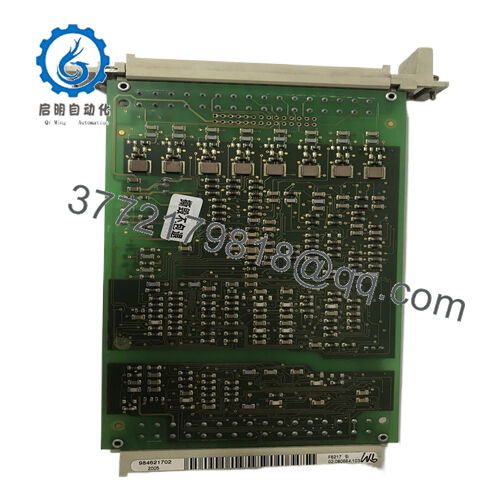

The HIMA F6217 984621702 intervenes as an 8-channel analog input module in HIMA’s F-series safety platform, tackling these transduction tribulations by providing galvanically isolated, 12-bit resolution captures for 0/4-20 mA currents and 0-5/10 V voltages, complete with self-testing for safe operation up to SIL 3. It asserts indispensability in architectures fusing field data with TMR CPUs, like ESD skids in upstream facilities or burner management in cogeneration plants, where channel density meets diagnostic depth without compromising redundancy. In SIS retrofits I’ve consulted on amid fractionation flares, crews clash with legacy cards lacking line monitoring or voltage divider options, demanding external isolators that bloat bays and belabor certifications. The HIMA F6217 984621702 neutralizes this by embedding safe isolation per channel and configurable scaling via SILworx, enabling seamless integration with H51q controllers for voted reads that mask transmitter faults. In the analog-aligned arena of industrial automation, it upholds the signal sanctity crucial for modular process control, where transducer truths translate into timely trips, converting latent liabilities into layered latencies that comply with CENELEC mandates.

By distilling diverse field formats into deterministic digits with built-in health checks, the HIMA F6217 984621702 liberates logic from linearity woes, empowering expansions that layer loops without latency lags. It’s the input integrity instrumented for those transduction-testing thresholds in process control, where a bit’s breadth bridges breaches, delivering the channel clarity that calibrates continuity and curbs cascades.

When embedding the HIMA F6217 984621702 into an H51q or H41q subrack for analog assimilation, it functions as the field faithful in your safety scaffold, accepting eight independent channels via screw terminals for 0/4-20 mA (250 Ω burden) or 0-5/10 V inputs with 12-bit A/D conversion and 100 kΩ impedance, then routing digitized values over the backplane to TMR CPUs for function block processing, while line monitoring detects opens/shorts for proactive alerts. It slots into a 3HE position in the 19-inch frame, sourcing 24 VDC from system rails and providing 1.96 kΩ voltage dividers for HART-compatible transmitters, positioning it at the I/O ingress where it isolates to 500 Vrms against surges, ensuring raw reads reach voted logic without noise nesting.

In action, it aligns with SILworx for scaling and filtering—say, configuring hysteresis for 20 mA overrange or enabling PT100 RTD modes via jumpers—while diagnostics poll channel integrity via system variables, flagging faults through Profinet IO or Modbus TCP to SCADA without loop interruptions. The 12-bit resolution yields 0.025% accuracy across spans, with self-tests cycling every scan (under 10 ms) to affirm SIL 3, and galvanic barriers shield from adjacent digital noise. No ancillary amplifiers; it normalizes on ingress, supporting redundant pairings where duplex modules vote for fault masking in SIL 4 paths.

This assimilation adapts in distributed designs, where it couples upstream with power modules and downstream with DO cards for hybrid loops, or extends via F8627 comms for OPC UA feeds in large ESDs. For upgrades, it mates legacy analog cards sans rewiring, its HART transparency easing smart transmitter ties. This isn’t isolated ingestion; the HIMA F6217 984621702 infuses analog assurance into the architecture, crafting process control that captures currents cleanly, anticipating the conversions that confirm compliance.

- HIMA F6217 984621702

- HIMA F6217 984621702

- HIMA F6217 984621702

| Specification | Details |

|---|---|

| Model Number | F6217 984621702 |

| Brand | HIMA |

| Type | 8-Channel Analog Input Module |

| Input Voltage | 24 V DC |

| Operating Temp Range | -15°C to +60°C |

| Mounting Style | 19-inch Subrack (3HE) |

| Dimensions | 221 x 133 x 100 mm |

| Weight | 0.3 kg |

| Interface/Bus | Backplane / Screw Terminals |

| Compliance | IEC 61508 SIL 3, CENELEC SIL 4 |

| Supported Protocols | Profinet IO, Modbus TCP |

| Typical Power Draw | 4 W |

Embracing the HIMA F6217 984621702 yields a stratum of signal sanctity that sharpens sensor scrutiny, where 8-channel isolation unmasks minute drifts in multi-loop arrays—consider resolving a 0.5 mA level creep in a reactor before it biases batches, forestalling the fill failures that furlough fractions of facilities and flare feedstock flares. Tailored for the transduction tempests of SIS shelves, it clinches ceaseless calibration through self-test sweeps and burden balance, so transmitter tethers or voltage variances don’t veil values, affording the acute analytics that align alarm apertures and amplify asset arcs without analog anxieties.

This module moreover molds maintenance mastery, its line-monitored metrics and fault flags hastening hit identification to isolated inputs over inclusive inspections—imperative in installations where enclosure entries exact effort and efficiency edges. Within subrack suites, it lightens layout loads by standardizing analog axioms, so loop legions launch sans scaling skirmishes or isolator impositions, funneling focus to forward-looking forecasts like HART health harmonics. Attendants attune to its status strobes for ledger looks, where channel cues cultivate confidence contextually, crafting crews that construe currents as clarions, not conundrums.

Deeper, the HIMA F6217 984621702 begets binary buoyancy, its 12-bit breadth bucking baseline bleeds to boost MTBF, while versatile vectors—mA to V—mold to manifolds minus module morasses. The ramifications radiate: reined reads that rescue returns, archive-adept audits for adherence airs, and the latitude to layer linear legacies for linear lifts, all latched in a module that doesn’t distort digits, but defines them into your automation’s discerning dominion.

In upstream ESD loops, the HIMA F6217 984621702 assimilates AI from pressure pilots amid explosive auras, leveraging backplane voting for critical system uptime via scaled shutdowns—pivotal for process control environments where input ignores could ignite interlocks and idle inflows. Its resolution rigor reveals range rifts under ramp rates, upholding high reliability in nodes navigating natgas networks.

For chemical batch reactors, it’s subracked to sample level analogs through corrosive chills, thriving against vapor volleys for continuous uptime, with mA metrics marshaling ESD on excursions. The HIMA F6217 984621702 advances modular integration, augmenting assemblies adroitly for recipe realms without analog additions.

In power plant feedwater controls, the HIMA F6217 984621702 tracks flow fractions in thermal tides, reinforcing fast data cycles for fault forwards in flux fluxes—harnessed in process control environments hewing to SIL 3 to hinder heat harms and husband hearth hauls.

F6215 – Voltage-only variant with 16 channels for high-density non-current apps.

F6220 – 4-20 mA specialist with HART passthrough for smart transmitter diagnostics.

F6201 – Universal AI upgrade with 16-bit resolution for precision RTD/TC fusion.

F8650X – Secure CPU host for the F6217 984621702 in H51q SIL 3 systems.

F8651X – Non-secure CPU alternative for cost-optimized H41q pairings.

F8627 – Ethernet comms companion for OPC-extended analog feeds in networked SIS.

F3237 – Digital input sibling for hybrid discrete-analog in ESD islands.

Before subracking the HIMA F6217 984621702, verify voltage variants—jumper for 5/10 V spans to match transmitters, and torque terminals to 0.5 Nm to avert contact creep; align scaling via SILworx offline sims to preempt polarity pitfalls. Slot into 3HE with ejectors engaged, then cycle power—steady green per channel confirms conversion quorum, but partials prompt probe reseats. Analog airs alter: allocate 50mm airflow in dusty domains, and bond chassis per EMC to curb coupled currents from cabling.

In stride, semestral sheath scans at screw junctions stave signal skips, notably in humid hazards—depower domains, ohm to ground, and log lags exceeding 100 kOhm. Quarterly, queue calibration checks with mA sources to vet voltage verities, archiving against apertures; anomalous amps augur amp adjustments under acquisition. Annual full-subrack proofs during halts—injecting sweeps—validate isolation sans sensor swaps, while SILworx syncs coincide with safety-wide updates, backed by config caches. These analog axioms, distilled from acquisition annals, dynamize the module’s mettle, deflecting the dim drifts that dull dynamic dawns.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626