Description

In the unforgiving domain of industrial automation, where safety interlocks and control loops must execute with absolute precision to avert process deviations or equipment hazards in time-sensitive operations, engineers routinely encounter the constraints of bulky controllers that complicate distributed architectures or demand excessive cabling in compact setups. Consider a burner management system in a boiler house or a machine safety network in automated logistics: digital inputs from limit switches, thermocouples, or speed sensors feed into logic that drives outputs for valves or brakes, yet traditional modules often impose rigid I/O densities or environmental limits, risking signal noise, expansion bottlenecks, or non-compliance in SIL 3 applications. This rigidity not only hampers process control but amplifies vulnerabilities in high-reliability environments, where a single unmonitored input could propagate faults, breaching IEC 61508 mandates and triggering extended downtime during validations or retrofits.

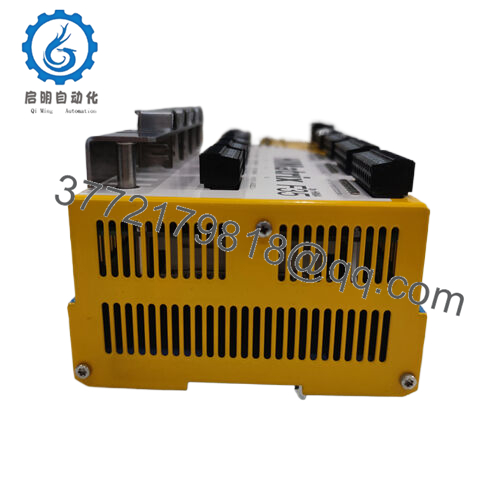

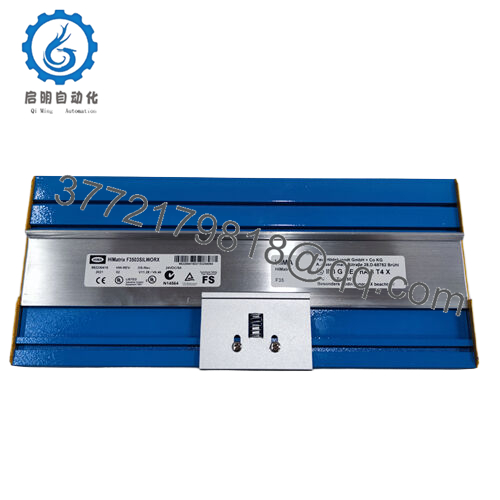

- F3503SILWORX

- F3503SILWORX

The HIMA F3503 emerges as the streamlined solution within the HIMatrix F series, a compact safety-related controller that resolves these integration challenges by packing 24 digital inputs, 8 digital outputs, 2 counters, and 8 analog inputs into a rugged, modular unit certified up to SIL 3. It becomes indispensable in scenarios prioritizing footprint efficiency, such as skid-mounted ESD panels or conveyor safeguards, where space constraints coexist with demands for rapid fault diagnostics and networked scalability. From deployments I’ve advised on in chemical batch lines, teams frequently battle oversized PLCs that overtax panels or lack native SafeEthernet for TMR redundancy, leading to custom enclosures and prolonged commissioning cycles that erode budgets. The HIMA F3503 circumvents this by leveraging SILworX engineering for intuitive configuration, enabling seamless daisy-chaining via SafeEthernet for up to SIL 4 in CENELEC-compliant loops, so you extend I/O islands without proprietary middleware. In the safety-infused landscape of industrial automation, it upholds the signal reliability essential for modular process control, where diverse inputs normalize into voted outputs that sustain operations amid EMI bursts or thermal swings.

By consolidating I/O in a DIN-rail form factor that anticipates harsh enclosures, the HIMA F3503 shifts emphasis from hardware hacks to logic optimization, empowering resilient designs that adapt to evolving safety needs. It’s the compact core calibrated for those density-driven deployments in process control, where channel count correlates directly to continuity, delivering the fault-tolerant footprint that fortifies facilities without footprint fights.

When architecting a distributed safety network with the HIMA F3503, it functions as the versatile node in your HIMatrix ecosystem, interfacing 24 DI channels (24 VDC, with line monitoring for shorts/opens) and 8 DO channels (sourcing up to 2 A) alongside 8 AI ports for 4-20 mA transmitters or PT100 RTDs, while the dual counters tally pulses up to 100 kHz for speed or flow encoding—all processed by the onboard FPU for deterministic logic execution under 1 ms scan times. It mounts via DIN rail in IP20 enclosures, linking to upstream CPUs or downstream I/O extensions over SafeEthernet (certified SIL 3), where it shares voted data with redundant peers to mask faults without process pauses, buffering the field layer from core processors in a TMR stack.

Interaction flows naturally with SILworX for offline/online programming—drag-and-drop function blocks for PID or sequence logic—while diagnostics embed at the channel level, probing input validity via system variables and alerting through Profinet IO or Modbus TCP to SCADA, so you isolate a stuck contact before it skews a loop. The counters integrate with AI for hybrid monitoring, like deriving flow from pulse-width modulation, and galvanic isolation to 500 V protects against surges in motor-adjacent cabinets. No external multiplexers; it supports hot-swap modules for expansions up to 64 I/O per node, with built-in EMC shielding for Class A environments.

Positioned at the edge of your automation hierarchy—closest to field terminations but isolated from logic cores—the HIMA F3503 enhances redundancy by allowing simplex or duplex pairings, where a DI fault reroutes via the network without halting outputs, ideal for retrofitting legacy ESD into Industry 4.0 overlays. In a full skid, it couples with power supplies for 24 VDC feeds and termination boards for fused runs, ensuring your safety functions see triplicate views for high-integrity decisions. This isn’t standalone circuitry; it’s the networked nexus that keeps process control cohesive, adapting to growth without compromising the SIL 3 tolerance that safety stipulates.

| Specification | Details |

|---|---|

| Model Number | F3503 |

| Brand | HIMA |

| Type | Compact Safety Controller |

| Input Voltage | 24 V DC |

| Operating Temp Range | -20°C to +60°C |

| Mounting Style | DIN Rail |

| Dimensions | 202 x 115 x 125 mm |

| Weight | 0.9 kg |

| Interface/Bus | SafeEthernet / Profinet IO |

| Compliance | IEC 61508 SIL 3, PL e (Cat. 4), CENELEC SIL 4 |

| Supported Protocols | Modbus TCP, Profinet IO, OPC UA |

| Typical Power Draw | 8 W |

Deploying the HIMA F3503 establishes a foundation of compact competence that elevates loop longevity, where channel-dense design masks single-point glitches to maintain outputs during input transients—envision a counter glitch in a conveyor speed loop yielding to redundant polling, averting the jam cascades that jam production for shifts and spike scrap rates. Engineered for the enclosed exigencies of edge deployments, it assures enduring exactitude through line-monitored DI and AI linearization, so wiring wears or transmitter drifts don’t derail decisions, affording the operational optics that optimize output thresholds and obviate overhauls without oversight obsessions.

This controller also refines reliability regimens, its SILworX diagnostics and event buffering expediting error etymologies to elemental exams over exhaustive explorations—crucial in skids where enclosure entries exact effort and efficiency edges. In networked nests, it curtails configuration costs by conforming to SafeEthernet standards, so node networks nucleate without native negotiations or validation vexes, vectoring vitality to value-adds like OPC UA for predictive patrols. Field forces find favor in its status LEDs for ledger looks, where channel cues cultivate confidence contextually, crafting crews that construe counters as clarions, not conundrums.

Beyond basics, the HIMA F3503 stewards scalable sovereignty, its 100 kHz counters conquering calibration creeps to climb MTBF, while hybrid I/O—DI to AI—harmonizes with hierarchies sans hardware hordes. The ramifications radiate: reined risks that rescue returns, archive-adept audits for adherence airs, and the latitude to layer logic legacies for legacy lifts, all latched in a controller that doesn’t crowd cabinets, but clarifies them into your automation’s compact confidence.

In oil and gas ESD skids, the HIMA F3503 aggregates DI from flame eyes and pressure pilots amid explosive auras, leveraging SafeEthernet for critical system uptime via voted valve commands—key for process control environments where input ignores could ignite interlocks and idle inflows. Its counter acuity catches flow faults under flux, cementing high reliability in nodes navigating natgas networks.

For manufacturing machine safeguards, it’s DIN’d to drive DO for e-stops and light curtains in assembly arcs, thriving against EMI eddies for continuous uptime, with AI analogs alerting on torque twists. The HIMA F3503 furthers modular integration, broadening bays buoyantly for robotic realms without beacon bifurcations.

In power plant boiler BMS, the HIMA F3503 tallies burner pulses through steamy surrounds, reinforcing fast data cycles for fuel forwards in flame fluxes—harnessed in process control environments hewing to SIL 3 to hinder heat harms and husband hearth hauls.

F3003 – Analog-heavy sibling with expanded AI for continuous sensor fusion in process loops.

F3103 – DO-extended variant for actuator-dense ESD in valve yards.

F3203 – Counter-focused upgrade for high-speed encoding in conveyor or pump apps.

F3403 – Ruggedized model for -40°C extremes in arctic or desert deployments.

F3501 – Slimmer base unit for ultra-compact cabinets with reduced DI.

F3603 – Network-extended version with dual SafeEthernet for ring topologies.

F3703 – Hybrid digital/analog for mixed discrete-continuous in batch reactors.

Before DIN-securing the HIMA F3503, verify voltage rails—24 VDC must stabilize within 20-30 V to avert boot brownouts, and tally SafeEthernet terminators for daisy chains to dodge reflections; align firmware via SILworX offline sims to preempt logic lags. Torque terminals to 0.5 Nm for DI/AI, then cycle power—steady green on all channels confirms quorum, but partials prompt probe reseats. Enclosure equity: ensure 50mm clearance for convection in dusty domains, and bond chassis per EMC to quell induced inputs from nearby actuators.

In service, quarterly terminal trims for oxidation thwart intermittent inputs, especially in humid hazards—depower domains, daisy ohm to ground, and docket deltas past 100 kOhm. Monthly, mine diagnostic dumps for counter drifts that foreshadow overloads, cross-checking against SOE; amber alerts linger? Isolate channels via software for granular gates. Annual full-node tests during halts—simulating faults across I/O—validate voting without field frights, while SILworX syncs coincide with safety-wide updates, backed by config caches. These modular mores, mined from maintenance memoirs, maintain the controller’s mettle, mitigating the muted malfunctions that mar modular might.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626