Description

In the high-stakes arena of industrial automation, where safety and precision hinge on robust signal acquisition in volatile environments, the challenge often lies in capturing reliable digital inputs from field devices without succumbing to electrical noise or integration complexity. Picture a mining operation or a wastewater treatment plant: proximity sensors, limit switches, or emergency stops feed binary signals into safety loops, but long cable runs, corrosive atmospheres, or stray EMI from heavy machinery can distort these inputs, risking false triggers or undetected faults that disrupt process control or endanger personnel. Traditional I/O modules may falter under these conditions, lacking the isolation, diagnostics, or compact modularity needed for SIL 3 compliance per IEC 61508, especially in distributed setups where space and uptime are non-negotiable.

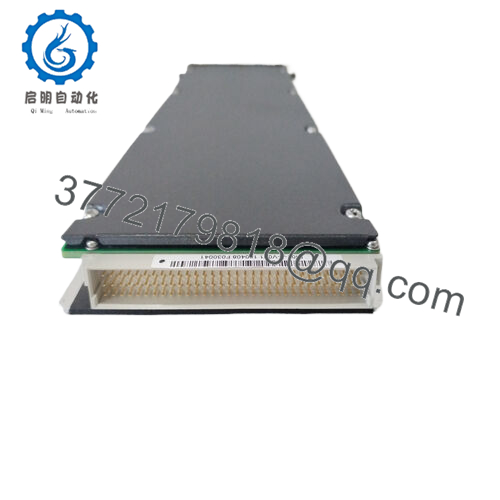

The HIMA BI01 steps up as a specialized digital input module within HIMA’s Planar4 series, engineered to deliver high-reliability signal acquisition for safety-critical applications. Designed for 16 single-channel inputs, it ensures clean capture of 24 VDC signals from sensors in harsh environments, with galvanic isolation that shields against transients up to 500 V. In scenarios like conveyor safety in steel mills or interlock monitoring in chemical reactors, the HIMA BI01 becomes a linchpin, providing modular integration that simplifies rack-based architectures while maintaining fault tolerance. Its compact 10 TE footprint and hot-swappable design make it a go-to for engineers upgrading legacy systems or scaling distributed I/O networks, reducing wiring complexity and ensuring I/O signal integrity without the overhead of external conditioners.

What sets the HIMA BI01 apart is its focus on diagnostic transparency and seamless tie-in with HIMA’s ELOP II or SILworX tools, enabling real-time fault detection without interrupting process flow. For teams battling tight panel space or regulatory scrutiny, it offers a plug-and-play solution that minimizes engineering time while maximizing system stability, turning potential signal vulnerabilities into robust inputs that keep safety loops airtight and operations fluid in the toughest industrial automation settings.

The HIMA BI01 integrates as a precision input node in the Planar4 rack system, slotting into the I/O layer to preprocess 16 digital channels before relaying them to central controllers like the F8640 CPU for safety logic execution. Each input accepts 24 VDC signals—sourced from NAMUR sensors, dry contacts, or proximity switches—with per-channel isolation that blocks noise bleed from adjacent circuits, ensuring clean data for applications like emergency shutdowns or alarm sequencing. The module performs onboard debouncing and validation, feeding serialized data to the backplane bus with sub-10 ms scan times, aligning with the deterministic needs of SIL 3 architectures.

In the automation stack, the HIMA BI01 sits field-side or centrally, depending on your cabling strategy, minimizing signal attenuation by keeping runs short or leveraging its surge suppression for longer drops. It supports redundancy via 1oo2 voting when paired with a duplicate unit, achieving fault tolerance with automatic failover in under 15 ms to prevent single-point disruptions. Diagnostics are intuitive: front-panel LEDs signal channel health—green for active, amber for faults—while cyclic self-tests log issues like wire breaks or shorts to the system’s event buffer, accessible via SCADA or HIMA’s engineering suite. The module’s hot-swap capability allows maintenance without powering down the rack, a critical edge in 24/7 process control environments.

Compatible with PROFIBUS DP for extended networking, the HIMA BI01 bridges to third-party DCS platforms without custom gateways, streamlining integration in hybrid setups. Its design prioritizes user-friendliness, eliminating the need for complex backplane rewiring and letting engineers focus on logic optimization rather than signal troubleshooting, making it a versatile cog in scalable, high-reliability safety systems.

| Specification | Details |

|---|---|

| Model Number | BI01 |

| Brand | HIMA |

| Type | 16-Fold Digital Input Module |

| Input Voltage | 24 VDC (18-30 V) |

| Operating Temp Range | -10 °C to +60 °C |

| Mounting Style | Planar4 Backplane Rack |

| Dimensions | 10 TE (50.8 mm width) |

| Weight | 0.22 kg |

| Interface/Bus | Planar4 Backplane Bus |

| Compliance | IEC 61508 SIL 3, CE, ATEX Zone 2 |

| Supported Protocols | Proprietary HIMA Bus, PROFIBUS DP |

| Typical Power Draw | 4.2 W |

Choosing the HIMA BI01 equips your safety system with a level of signal reliability that transforms potential weak links into fortified assets, ensuring consistent performance in environments where noise or corrosion could otherwise derail operations. Its galvanic isolation safeguards against transient spikes, extending module longevity and preventing the false trips that inflate downtime costs, with an MTBF exceeding 200,000 hours that reduces spares inventory needs. This reliability translates to fewer unplanned interventions, letting technicians shift from reactive fixes to strategic optimizations, with diagnostics that pinpoint channel faults via LED cues or SILworX logs, cutting troubleshooting from hours to minutes.

- BI01

Integration ease is a quiet strength: the HIMA BI01 slots into existing Planar4 racks without rewiring, supporting hot-swaps that minimize commissioning pauses and enabling seamless retrofits for ELOP II-based plants transitioning to SILworX. Its sub-10 ms response ensures safety functions align with process dynamics, critical for applications like valve interlocks where timing is everything. Over time, this compounds into lower lifecycle costs—fewer replacements, simplified audits, and protocol flexibility that integrates with legacy or modern DCS without middleware. Engineered for the engineer’s reality, the HIMA BI01 delivers peace of mind, ensuring your I/O layer performs predictably, letting you prioritize process yields over signal uncertainties in high-stakes automation ecosystems.

In mining operations, the HIMA BI01 captures conveyor belt sensor inputs, monitoring emergency pull-cords and alignment switches in dusty, high-vibration process control environments, ensuring critical system uptime by isolating signals against motor-induced EMI, preventing derailments in SIL 3-compliant safety loops.

Petrochemical refineries deploy the HIMA BI01 in flare stack monitoring, processing digital inputs from flame detectors and pressure switches in explosive Zone 2 areas, supporting fast data cycles for burner management systems where reliable signal capture averts false shutdowns and maintains regulatory compliance.

Water treatment facilities use it for pump station safeguards, ingesting signals from level sensors and flow switches amid humid, corrosive conditions, with the HIMA BI01’s diagnostics enabling continuous uptime by detecting wiring faults early, preserving clean water output in municipal networks.

F3221 – Higher-density 16-channel input module with extended diagnostics for large-scale sensor arrays.

F3236 – Modernized successor with NAMUR-specific inputs for hazardous area deployments.

BO01 – Complementary digital output module for direct actuator pairing in safety loops.

F8621X – Communication module to extend BI01 data via Modbus to remote SCADA systems.

F8640 – Central CPU for Planar4 racks, processing BI01 inputs for complex safety logic.

F7130A – Power supply module ensuring stable 24 VDC feeds for BI01 operations.

F3330 – Relay output alternative for high-current loads tied to BI01 input triggers.

Before installing the HIMA BI01, verify your Planar4 rack’s slot capacity—10 TE width requires a clear bay—and check backplane firmware against HIMA’s compatibility chart to prevent bus errors; the latest ELOP II or SILworX release is safest. Test input circuits for loop resistance below 100 ohms using a multimeter to rule out cable fatigue, and ensure grounding ties to a single equipotential point per IEC standards to block noise loops. Allocate 50 mm top/bottom clearance for airflow, critical in panels nearing 60 °C, and confirm input sources adhere to SELV/PELV for ATEX compliance.

For maintenance, adopt a streamlined routine: monthly, scan LEDs for steady green across channels—amber signals warrant a SILworX pull to diagnose opens or shorts—and verify input voltages stay within 18-30 VDC. Quarterly, simulate faults with a test harness to validate <10 ms response, logging results for IEC 61511 audits. In corrosive sites, inspect connectors biannually for pitting; clean with isopropyl post-depowering to avoid latch-ups. Hot-swap replacements need a pre-check for rack power stability to prevent bus resets. This focused upkeep, grounded in practical checks, keeps the HIMA BI01 humming, minimizing disruptions while maximizing signal fidelity in relentless industrial cycles.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626