Description

Real-World Use & Application Scenarios

In industries where safety and reliability are non-negotiable, such as oil and gas, power generation, chemical processing, and manufacturing, the HIMA 80105 984080105 communication module plays a critical role. It is designed for safety-related applications, enabling secure and efficient communication between safety controllers and other system components. This module helps operators maintain real-time monitoring and control within safety instrumented systems where timely data exchange is crucial for preventing incidents and ensuring continuous safe operation.

The 80105 supports data exchange for large, complex safety control infrastructures, including distributed control systems (DCS), ensuring safety system components communicate seamlessly with field devices and supervisory control layers. Its robust design and compatibility make it ideal for harsh industrial environments where resilience to electrical noise, temperature fluctuations, and mechanical stress is vital.

Product Introduction & Positioning

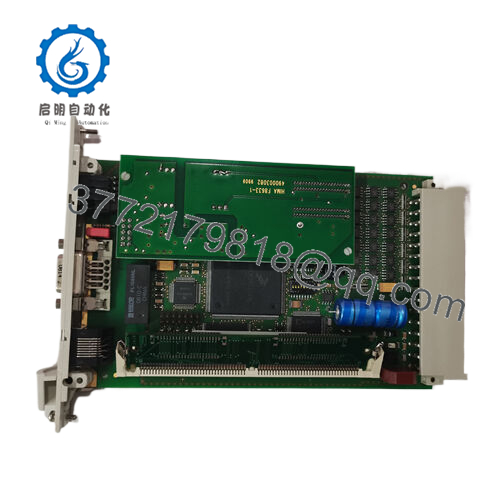

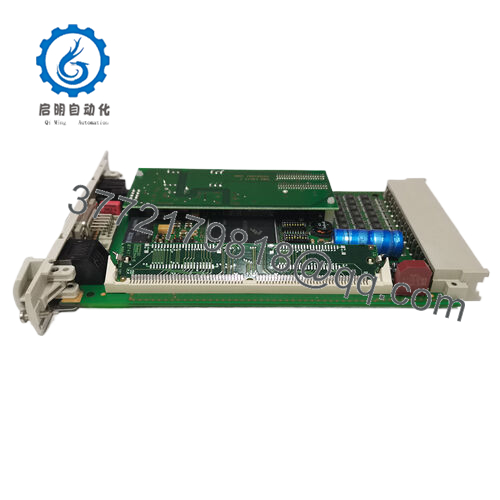

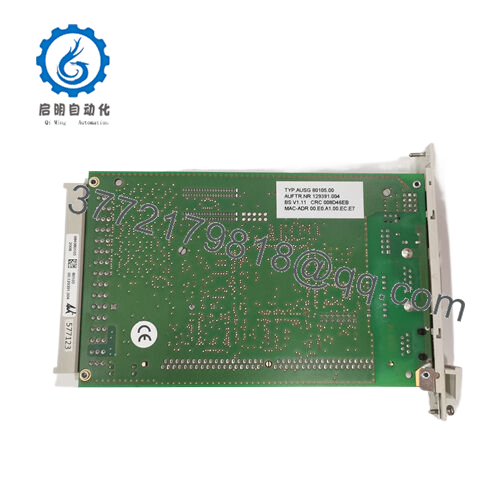

The HIMA 80105 984080105 is a versatile communication module tailored for HIMA safety systems, particularly the Planar4 platform. It supports multiple communication protocols including Modbus RTU, Modbus TCP, and PROFIBUS DP, facilitating integration across diverse industrial automation networks.

- 80105 984080105

This module provides two separate communication channels, allowing simultaneous, reliable data transfer in safety-related applications up to SIL 1. The 80105 serves as a vital interface bridging safety controllers with external devices, enhancing the overall system’s connectivity and operational integrity.

Its compact form factor makes the 80105 easy to install in control cabinets alongside other I/O and safety modules. Safety engineers favor this module for its ease of configuration, wide protocol support, and compliance with stringent safety standards.

Key Technical Features & Functional Benefits

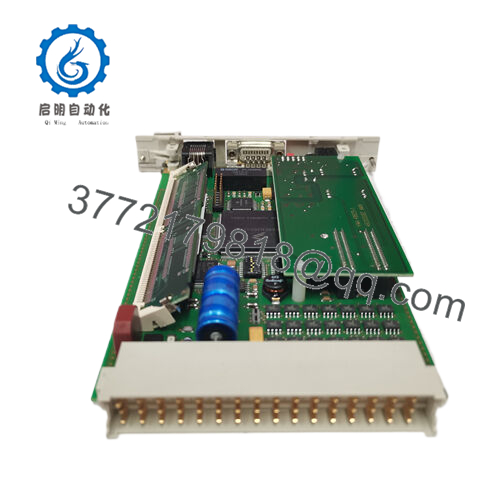

The HIMA 80105 supports high-speed data transfers up to 12 Mbps, ensuring timely communication essential for safety-critical processes. It offers versatile networking with support for Modbus RTU, Modbus TCP, and PROFIBUS DP protocols, facilitating seamless integration with numerous industrial automation platforms.

Operating on a 24 V DC power supply, it withstands harsh environments with an operating temperature range of -40°C to +85°C. With dimensions of approximately 40 x 100 x 22 mm and a lightweight design (~200 grams), it fits well in modular safety racks without demanding excessive space or weight allowances.

Diagnostic LEDs provide clear status feedback for each communication channel, aiding in rapid fault detection and system troubleshooting. This module’s design emphasizes operational reliability, low power consumption, and ease of maintenance, ensuring continuous safe functioning of industrial control systems.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | HIMA 80105 984080105 |

| Brand | HIMA |

| Product Type | Communication Module |

| Supported Protocols | Modbus RTU, Modbus TCP, PROFIBUS DP |

| Number of Channels | 2 |

| Data Transfer Rate | Up to 12 Mbps |

| Power Supply | 24 V DC |

| Operating Temperature Range | -40°C to +85°C |

| Dimensions | 40 mm x 100 mm x 22 mm |

| Weight | Approx. 200 grams |

| Certifications | SIL 1 |

| Mounting | Modular rack |

Related Modules or Compatible Units

HIMA F8650X CPU Module – Core safety controller CPU supporting advanced processing tasks.

HIMA F7133 Power Distribution Module – Enables power distribution across safety system components.

HIMA F8627X Coprocessor Module – Facilitates Modbus communication interoperability.

HIMA F6217 Analog Input Module – Supports safety-related analog input acquisition.

HIMA F3236 Digital Input Module – Provides multiple safety digital input channels.

HIMA F3330 Digital Output Module – Offers relay output channels for safety signaling.

HIMA F7126 Power Supply Module – Supplies stable and isolated power to safety modules.

Installation Notes & Maintenance Best Practices

Ensure the HIMA 80105 is installed in a clean, well-ventilated cabinet to maintain operating temperatures within specifications. Proper grounding and shielded cable connections are essential to minimize electromagnetic interference and maintain reliable communications.

Routine maintenance should include verification of communication LEDs and cable integrity, as well as firmware updates to maintain protocol compatibility and cybersecurity compliance. Regular functional testing via the safety management software helps detect issues early, ensuring continuous compliance with safety requirements.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626