Description

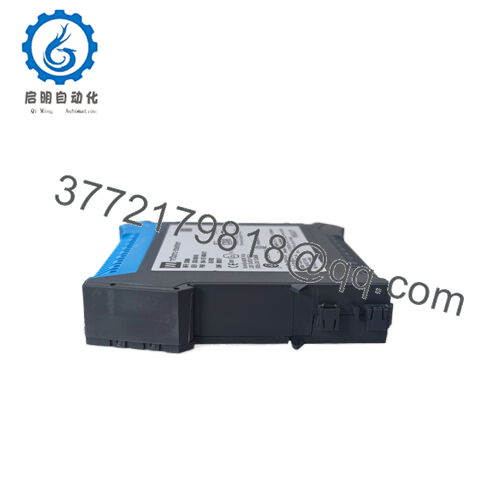

The GSI127 244-127-000-017-A2-B02 is a galvanic separation unit designed for industrial vibration monitoring systems, particularly in hazardous or demanding environments. Manufactured by Meggitt Vibro-Meter, this device provides electrical isolation to critical sensor signals, protecting measurement equipment and enhancing signal integrity in industrial automation applications involving rotating machinery condition monitoring.

This galvanic separation unit is commonly used in industries such as oil and gas, power generation, petrochemical, and heavy manufacturing, where equipment health and early fault detection are vital. The GSI127 244-127-000-017-A2-B02 helps mitigate electrical interference and ground loop issues that can corrupt sensor signals or reduce the reliability of vibration monitoring systems. Its multi-point monitoring capabilities contribute to safer operations and more accurate diagnostics, supporting proactive maintenance strategies in plants with critical rotating machinery.

Operating seamlessly within complex monitoring setups, the GSI127 unit isolates sensor outputs before signal processing, allowing standard signal conditioners or charge amplifiers to work within their specified performance ranges. This enhances the lifespan of connected electronics by preventing current surges or voltage spikes, especially important in explosive or hazardous zones where equipment protection is subject to stringent safety regulations.

- GSI127 244-127-000-017-A2-B02

The unit is engineered to meet international explosion-proof standards, suitable for installation in Ex environments. Its compact form factor simplifies integration into existing vibration monitoring racks or cabinets. A key feature is its consistent transfer characteristic sensitivity (1 V/mA ±1%), providing reliable and repeatable signal separation without degradation.

| Parameter | Value |

|---|---|

| Model | GSI127 244-127-000-017-A2-B02 |

| Brand | Meggitt Vibro-Meter |

| Product Type | Galvanic Separation Unit |

| Function | Electrical isolation for sensor signals |

| Application | Rotating machinery vibration monitoring |

| Sensitivity | 1 V/mA ± 1% |

| Weight | Approx. 140 g (0.31 lbs) |

| Dimensions | Compact, suitable for rack integration |

| Certification | Explosion-proof compliant (Ex certified) |

| Operating Environment | Hazardous/industrial zones |

| Compatible Equipment | Signal conditioners, charge amplifiers |

Related Products or Compatible Units

GSI128 – Similar galvanic separation unit with enhanced digital monitoring capabilities.

MCS4100 – Multi-channel vibration monitoring system compatible with GSI units.

GSI121 – Signal conditioner module designed to work alongside galvanic isolation units.

VBX200 – Portable vibration analyzer used as a complementary monitoring tool.

CDM200 – Charge amplifier module suitable for piezoelectric vibration sensors.

During installation, ensure the GSI127 244-127-000-017-A2-B02 is securely mounted to vibration-free surfaces and connected with shielded cables to reduce electromagnetic interference. Follow manufacturer wiring diagrams precisely to maintain explosion-proof integrity and compliance with hazardous area requirements. Proper grounding and avoidance of ground loops are critical for optimal galvanic isolation performance.

Routine maintenance involves periodically checking connection integrity, visual inspection for damage or corrosion, and verifying signal quality through diagnostic software compatible with the vibration monitoring system. Early detection of anomalies helps prevent costly machinery failures and reduces unplanned downtime in critical industrial operations.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626