Description

Real-World Use & Application Scenarios

In the fast-paced realm of industrial automation, the need for reliable and precise control systems is paramount. The GE WESDAC D20ME finds its essential role in environments where robust data processing and coordinated equipment control are critical. Commonly deployed in electrical substations, manufacturing plants, and complex process industries, this sophisticated controller enables continuous real-time monitoring, automation, and regulation of various industrial processes.

Industries such as power generation, utilities, oil and gas, and heavy manufacturing leverage the GE WESDAC D20ME for its exceptional handling of multi-channel input and output, supporting seamless digital and analog signal management. Its adaptability to harsh environmental conditions and support for industrial communication protocols cater to the demanding nature of these sectors. Engineers and system integrators rely on this model to enhance system responsiveness, ensure safety through intelligent diagnostics, and maintain process stability in control systems applicable in medium to large-scale automation setups.

Whether it’s facilitating communication between field devices and host computers or executing local automation algorithms, the GE WESDAC D20ME‘s role is pivotal in optimizing operational efficiency and reducing downtime across various industrial landscapes.

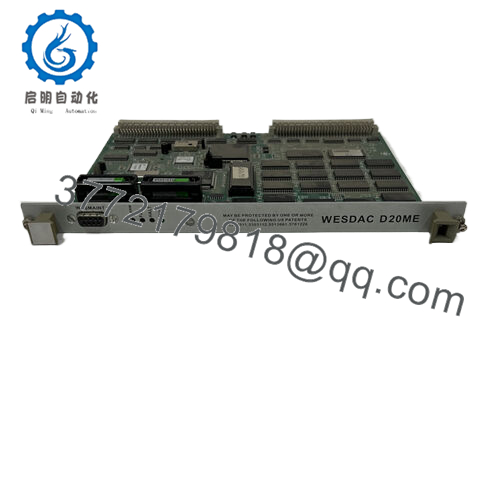

- WESDAC D20ME 18-MAR-13

Product Introduction & Positioning

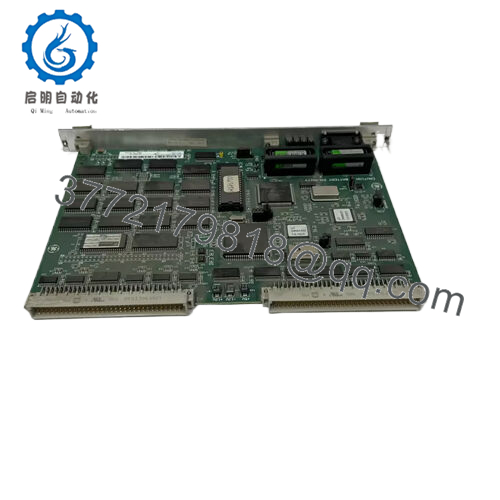

The GE WESDAC D20ME is a high-performance processor module designed as part of the broader GE WESDAC series, specifically tailored for use within the GE Multilin D20/D200 substation controller platforms. This integral I/O and processing unit functions as the core computing element managing data collection, execution of control logic, and interfacing with connected automation devices.

Positioned centrally within industrial control architectures, the GE WESDAC D20ME supports the automation platform by providing both processing power and real-time communication capabilities. It interfaces efficiently with D20 I/O modules, supports various serial and Ethernet communication standards, and is built to be modular to fit into scalable rack or panel-mounted chassis configurations.

Engineers and integrators value the GE WESDAC D20ME for its reliability, flexible programmability, and compatibility across multiple industrial communication protocols such as Modbus, IEC 61850, and DNP3. This versatility allows seamless integration into existing control systems, facilitating comprehensive substation or process plant management while promoting system expansion and adaptation with minimal disruption.

Key Technical Features & Functional Benefits

Built around a 32-bit FreeScale 68030 microprocessor operating at 40 MHz, the GE WESDAC D20ME delivers significant data processing power to handle complex industrial automation tasks with precision and speed. Its architecture supports high-resolution signal processing with 20-bit resolution and a maximum sampling rate of 100kSPS, enabling accurate real-time monitoring and control of intricate processes.

The hardware design reflects robustness tailored for industrial applications. Encased in an aluminum alloy housing with IP65 protection, the GE WESDAC D20ME withstands environmental challenges including dust, moisture, electromagnetic interference, and vibration, ensuring durability within harsh operational contexts. Its physical form factor supports flexible mounting options—both panel and DIN rail—simplifying integration into various control panels or racks.

Compatibility is a standout characteristic. The module supports a wide array of communication protocols such as Modbus, IEC 61850, Profibus, and DNP3, along with multiple communication ports including RS-232, RS-485, and Ethernet connections. This broad protocol support empowers integrators to connect the GE WESDAC D20ME seamlessly with legacy and modern automation components, enabling cohesive system operation and data exchange.

Long-term reliable operation is assured through high-quality component selection and intelligent diagnostics capabilities. The module offers built-in error detection, sensor disconnection warnings, and system health checks. Thermal efficiency and power supply adaptability allow consistent performance across varied industrial power environments. Engineers can expect extended service life, reduced downtime, and simplified maintenance thanks to these design considerations.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | WESDAC D20ME |

| Brand | General Electric (GE) |

| Product Type | Substation Controller Processor Module |

| Power Supply | 110 V – 380 V AC, 20 V – 60 V DC |

| Operating Temperature | -40°C to 70°C |

| Mounting | Panel mounting or DIN rail |

| Dimensions | Approx. 300mm x 200mm x 100mm |

| Weight | Approx. 0.5 kg |

| Processor | 32-bit FreeScale 68030, 40 MHz |

| Memory | 16 MB SDRAM, 2 MB Flash + SRAM |

| Interfaces | RS-232, RS-485, Ethernet |

| Supported Protocols | Modbus, IEC 61850, DNP3, Profibus |

| Environmental Rating | IP65 |

| Cooling | Natural ventilation |

Related Modules or Compatible Units

GE IC200ALG263 – Analog voltage input module for extending analog signal monitoring capabilities.

GE IC200ALG262 – VersaMax analog input module offering additional inputs for flexible system expansion.

GE IC200ALG432 – Mixed analog/digital I/O module compatible for enhanced device interfacing.

GE IC200CHS005 – Spring-style I/O carrier module facilitating easier module installation.

Multilin D200 Processor Board – Higher capacity processor for larger-scale substation control systems.

WESDAC 202 – Communication interface modules for legacy protocol support and line conditioning.

GE IC200CPU350 – Alternative CPU module providing different processing profiles for custom applications.

Installation Notes & Maintenance Best Practices

When preparing to install the GE WESDAC D20ME, ensure that the control cabinet provides sufficient clearance around the unit for proper airflow and access to connectors. The cabinet must offer a reliable grounding system to minimize electrical noise and protect the controller. Check compatibility with existing power supply conditions, considering its wide voltage input range. Allow adequate space for wiring harnesses and signal cabling to avoid interference and ensure easy maintenance access.

Maintenance involves regular inspection of terminal connections and visual checks for physical damage or signs of wear. Signal diagnostics can be performed remotely through communication interfaces to monitor operational status and detect potential faults early. Firmware and software updates should be applied in accordance with the manufacturer’s recommendations to keep the system secure and operating with the latest features. Periodic calibration of I/O channels supports sustained accuracy. Keeping a detailed maintenance log assists in reliability tracking and proactive servicing.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626