Description

In the complex tapestry of industrial automation, substation automation controllers often grapple with the chaos of disparate field signals—voltage sags from feeder faults, erratic breaker statuses amid storm surges, or fragmented telemetry from remote cap banks that leave operators blind to imbalances, risking blackouts, equipment stress, or cascading grid instabilities. These aren’t rare events; they’re the norm in utility substations, distribution feeders, or renewable integration points, where process control requires ironclad coordination to uphold high reliability for I/O signals across analog, digital, and serial streams. Engineers modernizing legacy bays frequently encounter silos: mismatched protocols that throttle data flows, limited port density forcing daisy-chain hacks, or insufficient diagnostics that mask incipient faults, all while NERC CIP mandates demand cyber-hardened, fault-tolerant architectures without full rip-and-replace overhauls. The result? Inflated integration timelines, vulnerability to EMI in outdoor enclosures, and eroded trust in SCADA overlays that should preempt disruptions.

Enter the GE WESDAC D20ME, the sixth-generation main processor module in GE’s venerable D20 substation automation platform, engineered to unify data acquisition, local logic execution, and host interfacing into a single, scalable powerhouse. It directly confronts the drive for system stability by embedding a 32-bit CPU with expandable I/O handling—up to seven RS-232/485 serial ports per module for DNP3, Modbus, or PROFIBUS DP—enabling precise polling of CT/VT inputs, breaker coils, or demand meters without bus overloads. Indispensable in scenarios like upgrading radial feeders to self-healing loops or layering DER controls in microgrids, the GE WESDAC D20ME facilitates modular integration via hot-swappable bins, streamlining expansions in 19-inch racks while its conformal-coated variants shield against humidity or dust in harsh vaults. For teams navigating high-vibration sites or cyber-threat vectors, this module’s built-in redundancy and event buffering turn signal pandemonium into orchestrated oversight.

Unchecked controller bottlenecks amplify far beyond the bay: they distort load forecasts in EMS platforms, delay auto-reclose sequences, and complicate forensic reviews under IEC 61850, eroding operational resilience in 24/7 grids. Through its real-time executive and ladder-logic interpreter, the GE WESDAC D20ME enforces sub-second determinism, letting you script custom interlocks—like voltage-based load shedding—while streaming timestamped snapshots to upstream RTUs or historians, fostering a cohesive process control fabric. It’s more than a processor; it’s the pulse that synchronizes substation intelligence, where every polled bit fortifies the grid’s adaptive edge in an era of volatile renewables and urban densification.

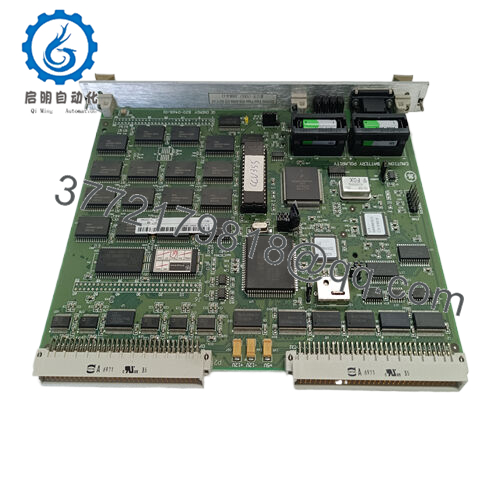

- GE WESDAC D20ME

- GE WESDAC D20ME

Slotting the GE WESDAC D20ME into your D20 ecosystem is like deploying a master conductor for your substation’s symphony—it mounts in standard D20 bins or 19-inch chassis, drawing 24/48 V DC from isolated supplies while arbitrating up to 49 serial ports across multi-module configs, capturing raw field data from DI/DO (up to 64 points) or AI/AO channels before synthesizing it via its 32-bit core for handoff to host systems like GE’s e-terra or third-party SCADA via Ethernet gateways. Anchored in the Purdue model’s level 2, it bridges physical layers—wiring to recloser coils or synchrophasors through screw terminals—then executes user-defined algorithms in its onboard memory (up to 512 KB RAM/EEPROM), supporting failover through dual-redundant CPUs that mirror states without process hiccups.

In a field rollout, you’d populate it in a D20ME II rack, configuring protocols through GE’s WorkStation tool for DNP3 Level 2 event reporting, then enable diagnostics like port health polls that flag wiring faults via front-panel relays—all while its PROFIBUS DP slave mode integrates with PLCs for hybrid bays, minimizing latency in fast-event cycles like fault clearing. This module doesn’t commandeer; it collaborates, with expandable slots for modem add-ons (e.g., Telenetics 14.4K) to extend reach over leased lines, and built-in timers for precise sequencing of cap switches or transformer taps, adapting to architectures from standalone feeders to looped urban grids. Tie it to fiber optics for wide-area meshes, and it elevates raw telemetry to enriched datasets, with oscillography buffers that capture 32 cycles for post-disturbance forensics. The GE WESDAC D20ME excels in this nexus, harmonizing I/O chaos into a resilient backbone that scales with your grid’s ambitions, from basic metering to advanced ADMS overlays.

| Specification | Details |

|---|---|

| Model Number | WESDAC D20ME |

| Brand | GE |

| Type | Substation Automation Main Processor |

| Input Voltage | 20-60 V DC / 100-300 V DC or 85-264 V AC |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | 19″ Rack / D20 Bin Mount |

| Dimensions | 482 x 44 x 260 mm (rack module) |

| Weight | 1.5 kg |

| Interface/Bus | RS-232/485 / PROFIBUS DP |

| Compliance | IEEE C37.90, CE, UL, NERC CIP |

| Supported Protocols | DNP3, Modbus RTU/TCP, PROFIBUS |

| Typical Power Draw | 10 W |

Opting for the GE WESDAC D20ME establishes a cornerstone of reliability honed for grid endurance, where its dual-watchdog timers and ECC memory scrub faults before they propagate, sustaining 99.99% availability through voltage dips that would trip lesser units— a direct safeguard in process control where a stalled poll delays reclose by cycles, averting outages that tally in megawatts. This engineered tenacity means your serial streams hold baud integrity across 10 km runs, with adaptive baud rates that self-negotiate to quash dropouts, ensuring consistent performance in thermal-cycled vaults without the recalibration drifts that erode metering baselines over quarters.

The maintenance uplift is equally compelling: onboard self-tests cycle through port loops on power-up, exposing handshake errors via SNMP traps that integrate with your asset manager, condensing troubleshooting from hours of cable traces to dashboard glances and easing compliance with FERC audits. Integration flows intuitively too, with drag-and-drop logic builders that mate to existing SEL relays sans converters, accelerating bay proofs by weeks and unburdening crews for firmware evolutions over wiring wars. Built for conformal-coated fortitude against salt air or seismic shakes, the GE WESDAC D20ME guarantees long-term performance, anchoring event clocks to GPS precision so your disturbance records align faultlessly, reducing the engineering toll of post-event reconstructions.

For grid visionaries, its modular bin design supports seamless CPU swaps under load, minimizing flash exposures during upgrades, while optional Ethernet modules unlock synchrophasor feeds for PMU analytics—compressing total cost of ownership by perpetuating D20 legacies into digital twin realms. This processor doesn’t just compute; it conserves, infusing substation command with the prescience to navigate flux without fracture.

In transmission substations, the GE WESDAC D20ME directs breaker automation, where process control environments mandate high reliability amid arc flashes and load transients—housed in climate-sealed racks, its PROFIBUS polls synch-check relays for seamless transfers, ensuring critical system uptime in fast data cycles that isolate faults before they span zones. DNP3 outputs feed EMS for contingency modeling, preempting overloads in high-inertia grids.

Distribution utilities deploy it for feeder management, aggregating analog currents from CTs in storm-vulnerable cabinets under humid assault— the module’s isolation buffers EMI from underground vaults, delivering continuous uptime for voltage regulation in process control loops tied to reclosers, where a lagged status risks flicker complaints. In solar farm switchyards, the GE WESDAC D20ME orchestrates inverter ride-throughs, with Modbus daisy-chains suited to dusty, wind-battered arrays—upholding high reliability for anti-islanding in process control environments synced to SCADA for curtailment minimization.

D20ME II – Next-gen CPU upgrade with enhanced Ethernet for IEC 61850 native support

D20C – Analog/digital I/O companion for dense field termination in hybrid bays

D20RT – Real-time clock module add-on for precision timestamping in event logs

D20MX – Expanded chassis variant for multi-processor redundancy in large substations

580-2004 – 20-60 V DC power supply mate for low-voltage DC-fed installs

520-0120 – V.23 modem accessory for legacy dial-up remote access

D-20 – Base RTU host for hierarchical D20ME integration in master-slave setups

Before powering the GE WESDAC D20ME, audit serial port mappings against your protocol stack—clash IDs on RS-485 multidrops can echo commands—and verify chassis airflow exceeds 50 CFM, as stacked bins push heat toward 70°C limits; a post-rack IR scan confirms even profiles. Firmware at 6.0 or later enables PROFIBUS DP-V1; pull the binary from GE’s portal and validate via console loopback to avert init stalls. If extending serial runs, cap terminators at 120 ohms and ground shields at one end per TIA-485, plus dry-test a port subset with a protocol analyzer to affirm no parity flips before live tie-in.

Once fielded, checks are surgical: monthly, query the diagnostic bus for port utilization—over 80% loads cue a baud downshift—and inspect terminal glands quarterly in coastal vaults to preempt moisture wicks, a silicone seal refresh often suffices sans outage. GE prescribes biannual logic simulations, injecting mock faults to trace execution paths against code baselines, logged in XML for audit trails. In remote grids, configure SNMPv3 for over-the-air health dumps, surfacing trends like rising CRC errors before they strand a feeder. This focused regimen keeps it primed, intruding sparingly on your grid cadence.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626