Description

GE WES5120 2340-21004 is a specialized module designed specifically for industrial control and data management systems. It is an important component of GE’s industrial product ecosystem, designed to work collaboratively with other GE equipment and systems, while being compatible with a wide range of third-party devices.

WES5120 2340-21004

This module serves as a critical interface in the control system architecture. It can serve as a bridge between different subsystems to achieve seamless communication and data transmission. For example, it can connect a programmable logic controller (PLC) with various sensors and actuators on site. This connection enables the PLC to receive real-time data from sensors, such as pressure sensors in chemical factories or position sensors in manufacturing robots, and send control signals to actuators such as motors or valves.

WES5120 2340-21004

Main features and advantages:

One of the main advantages of GE WES5120 2340-21004is its high-speed data processing capability. Equipped with advanced processing units, it can process large amounts of data in real-time. In a fast-paced manufacturing environment, multiple sensors continuously send data, and this module can quickly analyze and respond to this information. This speed is crucial for making immediate control decisions and preventing potential production delays or errors.

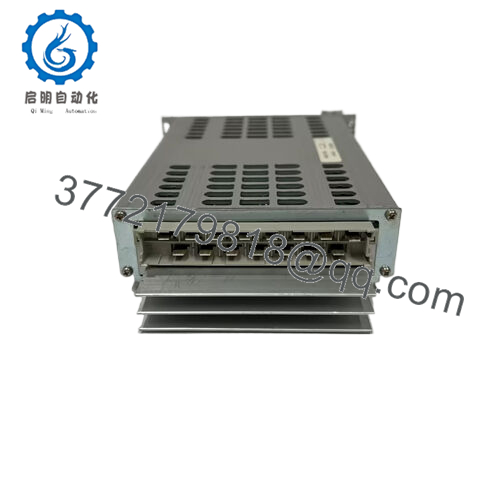

In terms of hardware design, GE WES5120 2340-21004 is sturdy and durable. It can withstand harsh industrial environments, including extreme temperatures, high humidity, and electrical interference. Its compact size also facilitates installation in narrow spaces inside control cabinets, saving valuable space in industrial environments.

Compatibility is another major advantage of this module. It supports multiple communication protocols and can interface with various devices from different manufacturers. Whether connected to outdated legacy systems or state-of-the-art industrial equipment, GE WES5120 2340-21004 can achieve seamless communication. In today’s industrial environment, different systems often require collaborative work, and this interoperability is particularly important.

Long term reliability is ensured through an efficient thermal management system. This module is designed for effective heat dissipation, preventing overheating even during prolonged high load operation. Combined with high-quality components, this helps to extend the service life, reduce the need for frequent replacement, and lower maintenance costs over time.

WES5120 2340-21004

Technical specifications:

Model WES5120 2340-21004

Brand GE

Type: Industrial Control and Data Management Module

Installation method: DIN rail installation, panel installation

Interface Ethernet, RS-485, etc

Certification CE, UL

Natural convection and forced air cooling methods for heat dissipation

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

WES5120 2340-21004

Application areas:

In manufacturing factories, especially those involving high-precision production processes, this product plays a crucial role. For example, in an electronic manufacturing factory that assembles circuit boards, GE WES5120 2340-21004 can be used to control and monitor the precise movement of robotic arms. These robotic arms require extremely high precision to place tiny electronic components, and this module ensures perfect command execution, reduces errors, and improves overall production quality.

In the healthcare field, GEWES5120 2340-21004 can also be used in the hospital’s medical equipment management system. It can be used to manage the data flow between different diagnostic devices and the central patient information system. For example, it can facilitate the transmission of X-ray or MRI scan data from imaging devices to the hospital’s Picture Archiving and Communication System (PACS), ensuring that doctors can obtain patient images and reports in a timely and accurate manner.

GE WES5120 2340-21004is also widely used in power generation facilities. In power plants, it can be used to control and monitor the performance of turbines. By continuously analyzing the data provided by sensors installed on the turbine, such as temperature, vibration, and speed sensors, this module helps optimize the operation of the turbine, improve energy efficiency, and reduce the risk of failure. These are just a few examples of the diverse practical application scenarios of GE WES5120 2340-21004, which proves that it is an indispensable part of the overall system in industrial automation and related fields, meeting the needs of reliable control and data management in the industrial automation field.

WES5120 2340-21004

Related products:

GE WEA13-13 2508-21001- This related module can be used in conjunction with GE WES5120 2340-21004 for more comprehensive industrial control settings. Although WES5120 2340-21004 may focus on data management and certain control functions, WEA13-13 2508-21001 can handle additional control tasks, complementing each other to build a more powerful control system.

GE WESDAC D20ME – It is a simulation related module. GE WES5120 2340-21004 can work in conjunction with WESDAC D20ME when handling applications that require simultaneous processing of digital and analog data. For example, in a process control system, some sensors provide analog signals while others provide digital signals, and these two modules can effectively collaborate to manage and process all data.

GE IS200TDBSH2ACC – This module supports GE WES5120 2340-21004 in more complex control systems. It can process specific types of signals or perform additional processing tasks, which WES5120 2340-21004 can utilize to achieve the overall operation of the system.

GE IC697BEM711- complementary to GE WES5120 2340-21004, can be used to expand the control capabilities of the system. For example, if WES5120 2340-21004 is already managing a certain number of control loops, adding IC697BEM711 can handle more loops and enhance overall control functionality.

GE VMIVME1150- can be integrated with GE WES5120 2340-21004 into industrial computer-based control settings. It may provide additional computing power or memory resources, which can be very beneficial when WES5120 2340-21004 needs to process large amounts of data or run more complex algorithms.

GE SR745-W2-P1-G1-HI-A-L-R – This module can be used in parallel with GE WES5120 2340-21004 for applications that require specific signal conditioning or monitoring functions. It can enhance overall system performance by providing additional signal correlation processing that WES5120 2340-21004 may not be able to handle separately.

GE IS215UCVEM08B – It has different digital input/output capabilities and can be used in conjunction with GE WES5120 2340-21004 to create a more comprehensive digital control solution for industrial processes. These two modules can work together to more effectively manage digital signals in the control system.

Installation and maintenance:

It is crucial to carefully plan the installation location before installing GE WES5120 2340-21004. Ensure that the control cabinet has sufficient space to accommodate the module and all related wiring. The control cabinet should be properly grounded to prevent electrical interference and ensure the safety of the entire system. In addition, maintain appropriate gaps around the module to ensure good ventilation. Overheating can seriously affect the performance and service life of modules, so good air circulation is crucial.

For maintenance, it is recommended to conduct regular visual inspections. Check for any signs of physical damage, such as cracks or loose connections. Monitor the status indicator lights of the monitoring module to detect potential issues as early as possible. Signal diagnosis should be conducted regularly to ensure the accuracy of transmitted and received data. GE typically provides software tools for these diagnostics, which can be used to quickly identify and resolve any communication or signal related issues. In addition, keep the firmware of the module updated. GE will regularly release firmware updates to enhance performance, fix vulnerabilities, and improve security. Updating firmware helps ensure that GE WES5120 2340-21004 maintains optimal performance over time.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626