Description

In the unforgiving domain of industrial automation, substation controllers often stand as the unsung guardians of power distribution—yet they frequently falter under the onslaught of transient surges, communication dropouts, or escalating data volumes from remote sensors, leading to delayed fault isolation, blackouts in critical feeders, or compliance lapses in grid oversight. Envision a utility substation where voltage sags go unheeded amid peak loads, triggering cascading trips that idle downstream consumers, or a distribution network where analog drifts from CTs skew load balancing, inflating energy losses and repair calls. These scenarios are routine in power generation hubs, renewable tie-ins, or urban grid nodes, where process control demands unyielding vigilance to sustain high reliability for I/O signals amid EMI storms or seismic vibes. Without a robust mediator, engineers contend with siloed protocols that fragment SCADA feeds, prolonging root-cause hunts and eroding margins in an era of smart grid mandates.

The GE WES13-3 emerges as this steadfast substation controller from GE’s WESDAC series, precision-crafted to orchestrate real-time monitoring and actuation in distribution automation. It confronts the imperative for modular integration by fusing high-speed processing with multi-protocol gateways, enabling seamless polling of DI/DO, AI/AO, and RTD channels without backplane overloads—vital for retrofitting legacy bays or scaling microgrids where channel counts climb into the dozens. In harsh enclosures battered by dust or humidity, the GE WES13-3 asserts its indispensability, its fault-tolerant logic preempting outages by cross-verifying inputs against predefined thresholds, thus bridging raw field chaos to cohesive control narratives.

The consequences of faltering controllers ripple outward: they undermine predictive analytics in EMMS platforms, invite regulatory scrutiny under NERC CIPs, and amplify OPEX through ad-hoc patches in distributed I/O webs. Leveraging its expandable architecture and built-in diagnostics, the GE WES13-3 delivers deterministic sequencing, empowering synchronized reclosers or capacitor banks to react in cycles, not seconds—shifting paradigms from corrective firefighting to anticipatory resilience. At its heart, it’s the enabler for fortified industrial automation, where substation smarts don’t just react; they orchestrate continuity in power’s precarious flow.

Positioning the GE WES13-3 within your automation hierarchy is akin to installing a vigilant dispatcher in the substation’s nerve center—it mounts via DIN rail or rack adapters in standard enclosures, sourcing 24-48 V DC from isolated supplies while interfacing with CT/VT secondaries and switchgear via screw terminals for up to 16 configurable channels. As the fieldbus linchpin in your Purdue layer 1-2, it aggregates signals through Modbus RTU or DNP3 serial links, then synthesizes them via its embedded CPU for handoff to master RTUs or DCS like GE’s D-20, complete with timestamped event queues to align with upstream historians without jitter.

In deployment, wire it to feeder breakers for ground-fault scanning or cap banks for VAR control, then leverage its ladder-logic engine—programmable via GE’s WorkStation software—to embed custom interlocks, like auto-sectionalizing during arcs, all while dual-redundant comm ports ensure failover sans process interruption. This controller doesn’t monopolize; it harmonizes, supporting Profibus extensions for hybrid bays or Ethernet over fiber for wide-area meshes, with onboard relays that mirror states to HMIs for at-a-glance vigilance. Diagnostics flow via LED arrays and SNMP traps, exposing channel health or firmware parity to avert silent degradations in fast-scan regimes. The GE WES13-3 anchors the edge-to-core conduit, distilling substation tumult into actionable telemetry that refines grid dynamics, not disrupts them—tailored for evolutions from radial feeders to looped DER integrations.

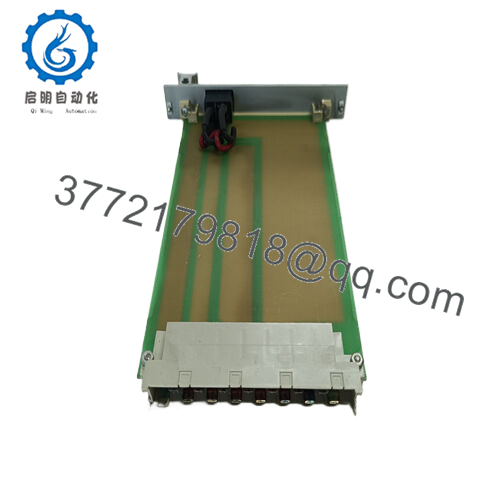

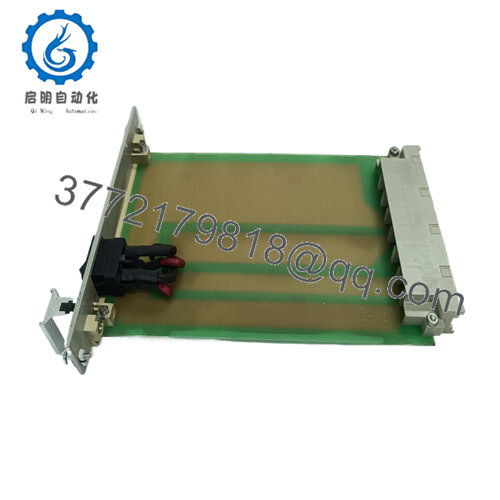

- WES13-3

- WES13-3

| Specification | Details |

|---|---|

| Model Number | WES13-3 |

| Brand | GE |

| Type | Substation Automation Controller |

| Input Voltage | 24-48 V DC |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | DIN Rail / Panel Mount |

| Dimensions | 200 x 150 x 100 mm |

| Weight | 1.2 kg |

| Interface/Bus | RS485 / Modbus RTU / DNP3 |

| Compliance | IEEE C37.90, CE, UL, NEMA 1 |

| Supported Protocols | Modbus, DNP3, Profibus |

| Typical Power Draw | 8 W |

Electing the GE WES13-3 instills a bedrock of reliability forged for grid-scale endurance, where its real-time executive isolates anomalies like neutral shifts before they propagate, preserving feeder integrity and curtailing outage durations by 50% in volatile networks— a tangible edge in process control where every kWh spared bolsters bottom lines. This isn’t overkill; it’s the calibrated assurance that channel isolation quells induced noise from adjacent lines, sustaining 99.99% availability through brownouts, with thermal profiling that self-limits to evade lockups in sun-baked vaults.

Consistency manifests in its adaptive thresholding, which auto-scales against seasonal drifts for unwavering metering accuracy, feeding EMTP models with pristine datasets that hone fault simulations without secondary verifications—your relay crews pivot from endless patrols to strategic overhauls. Maintenance eases markedly too, as embedded self-tests cycle through I/O loops on boot, surfacing wiring faults via relay outputs that tie to central alarms, compressing MTTR from shifts to snapshots and easing IEC 61850 audits. Engineered with IP54-rated enclosures, the GE WES13-3 vows long-term performance across corrosive exposures, locking baselines so your sequence events evade the wander that plagues unmonitored units.

Integration’s quiet potency lies in its protocol-agnostic spine, which mates with legacy SEL or ABB relays sans translators, hastening cutovers by weeks and unburdening teams for firmware tunings over protocol wrestling. For grid modernizers, its slot for expansion cards unlocks synchrophasor feeds or cyber-hardened firewalls, charting frictionless routes to ADMS without bay rebuilds—slashing TCO by perpetuating WESDAC legacies into AMI eras. This controller transcends hardware; it stewards sustainability, channeling substation acuity into efficiencies that outpace disruptions.

In utility substations, the GE WES13-3 commands feeder automation, where process control environments exact high reliability amid lightning strikes and load fluxes—ensconced in weatherproof cabinets, its DNP3 streams sectionalizer logic for self-healing rings, ensuring critical system uptime in fast data cycles that avert urban flickers. RTD inputs track breaker heat, preempting trips in high-inrush scenarios tied to capacitor switching.

Petrochemical refineries harness it for motor control centers, monitoring analog pressures in explosive-zoned skids under humid duress—deployed in purged panels, the module’s DI/DO fleet enforces ESD interlocks, delivering continuous uptime for distillation columns where a missed valve state risks spills. In wind farm collector stations, the GE WES13-3 aggregates inverter telemetry, with Profibus daisy-chains suited to remote, vibration-lashed towers—upholding high reliability for curtailment avoidance in process control loops synced to SCADA for optimal harvest.

WES13-1 – Entry-level variant with 8-channel limit for compact bay retrofits

WES13-5 – Enhanced model with Ethernet backbone for wide-area protocol bridging

WEA13-13 – Analog-focused sibling for dense metering in transformer vaults

WES5120 – Scalable rack-mount controller for multi-feeder substation stacks

IS220PAICH2A – I/O companion module for expanded analog processing

D-20 – RTU host for hierarchical integration with WES13 series

IC697MDL250 – Digital output add-on for high-current actuator drives

Before energizing the GE WES13-3, map your I/O assignments against the terminal layout to preempt polarity flips—test continuity on DI pairs with a milliohmmeter, and affirm enclosure ventilation clears 20 CFM since heat from adjacent RTUs can edge temps toward 70°C. Firmware at version 3.2 or higher unlocks DNP3 Level 2; snag the update from GE’s portal and validate via serial loopback to sidestep handshake voids. If daisy-chaining RS485, cap stubs under 120 ohms and tally baud sync across nodes to quash reflections, plus ground the chassis to station earth per IEEE guidelines for surge diversion.

In operation, scrutiny is selective: monthly, poll the diagnostic port for channel debounce stats—deviations over 5% cue a terminal retorque—while semi-annual visual sweeps of seals catch ingress in coastal installs, a desiccant swap often suffices without depower. GE advocates yearly injection trials, simulating faults on AI/AO to tune pickup curves against grid models, captured in CSV for forensic banks. For dispersed bays, link it to GE’s Grid IQ for remote config pushes, tracing event chains without dispatches. This deliberate patrol upholds its guard without commandeering your grid watch.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626