Description

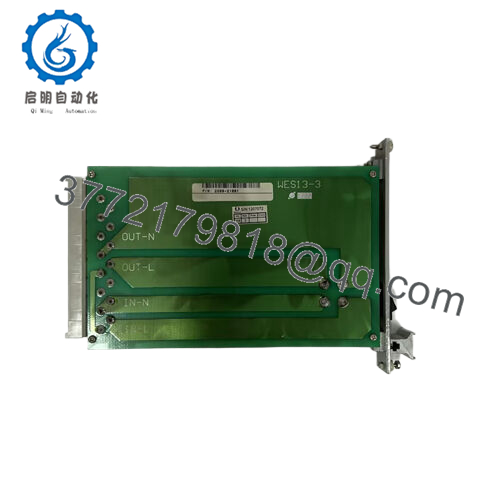

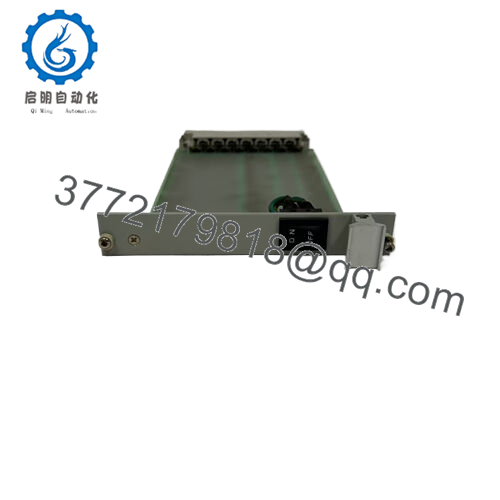

GE WEA13-13 2508-21001 is a module designed specifically for industrial control and automation systems. It is a key component in the GE industrial product ecosystem, capable of seamless integration with other GE brand equipment and systems.

WEA13-13 2508-21001

This module is designed to handle specific control and communication tasks in the control system architecture. It can serve as an interface between different subsystems, facilitating the smooth flow of data and commands. For example, it can connect a programmable logic controller (PLC) with various sensors and actuators on site. In this way, it enables the PLC to receive real-time data from sensors such as temperature, pressure, or position sensors and send control signals to actuators such as motors or valves.

WEA13-13 2508-21001

Main features and advantages:

One of the outstanding features of GE WEA13-13 2508-21001 is its high-speed data processing capability. It is equipped with advanced processing units that can process large amounts of data in real-time. In a fast-paced manufacturing environment, multiple sensors continuously send data, and this module can quickly analyze and take action based on this information. This speed ensures that control decisions can be made in real-time, preventing potential production delays or errors.

In terms of hardware design, GE WEA13-13 2508-21001 is sturdy and durable. It can withstand harsh industrial environments, including extreme temperatures, high humidity, and electrical interference. Its compact size also makes it easy to install in narrow spaces inside control cabinets, saving valuable space in industrial environments.

Compatibility is another strength of this module. It supports multiple communication protocols and can interface with various devices from different manufacturers. Whether connected to legacy systems or the latest advanced industrial equipment, GE WEA13-13 2508-21001can establish seamless communication. This interoperability is crucial in today’s industrial environment, as different systems often require collaborative work.

Long term reliability is ensured through its powerful thermal management system. This module is designed for efficient heat dissipation and can prevent overheating even during long-term high load operation. Combined with high-quality components, this helps to extend service life, reduce the need for frequent replacement, and lower maintenance costs over time.

WEA13-13 2508-21001

Technical specifications:

Model WEA13-13 2508-21001

Brand GE

Type: Industrial Control Module

Installation method: DIN rail installation, panel installation

Ethernet interface RS – 485

Certification CE, UL

Natural convection and forced air cooling methods for heat dissipation

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

Application areas:

In manufacturing factories, especially those involving large-scale production lines, this product is crucial for maintaining smooth production processes. For example, in the automotive manufacturing industry, the collaborative operation of multiple robotic arms, conveyors, and quality inspection sensors is crucial, and GEWEA13-13 2508-21001 ensures that every production step can be executed accurately. It manages the complex control sequence that drives the assembly of automotive components, minimizing errors and reducing production bottlenecks to the greatest extent possible.

The food and beverage industry is also highly dependent on GEWEA13-13 2508-21001. In the beverage filling plant, it controls the filling equipment to ensure accurate liquid level for each bottle of beverage. At the same time, it also manages packaging machinery and coordinates the movement of bottles from the filling station to the labeling and capping areas. Through this approach, it helps to maintain high-speed, high-precision production while meeting consumer demands, and adhering to strict hygiene and safety standards.

In power generation facilities, whether it is coal-fired power plants or modern wind farms, GE WEA13-13 2508-21001 is used to monitor and control various parameters. In a wind farm, it can manage the pitch and yaw control systems of wind turbines, optimizing energy production based on wind speed and direction. In power plants, it may participate in controlling the combustion process of boilers, ensuring efficient use of fuel and stable power output.

Related products:

GE WES5120 2340-21005- has similar functionality but may have different input/output configurations, making it suitable for applications with specific I/O requirements.

GE IS200TDBSH2ACC – This module can work in conjunction with GE WEA13-13 2508-21001 in more complex control systems. It may handle different types of signals or perform additional processing tasks to support the operation of the entire system.

GE IC697BEM711- As a supplement to GE WEA13-13 2508-21001, it can be used to expand the control capabilities of the system, such as by adding more control loops or handling more field devices.

GE VMIVME1150- can be integrated with GE WEA13-13 2508-21001 in certain industrial computer-based control settings. It may provide additional computing power or memory resources for applications with higher demands.

GE SR745-W2-P1-G1-HI-A-L-R – This module can be used in parallel with GE WEA13-13 2508-21001 and is suitable for applications that require specific signal conditioning or monitoring functions, improving the overall performance of the system.

GE IS215UCVEM08B – It has different digital input/output capabilities and can be used in conjunction with GE WEA13-13 2508-21001 to create a more comprehensive digital control solution for industrial processes.

GE DS200UCPBG6AFB – may provide additional communication or control functions that can be integrated with GE WEA13-13 2508-21001 to optimize the performance of industrial automation systems, particularly in data processing and system integration.

Installation and maintenance:

Before installing GE WEA13-13 2508-21001, the installation location must be carefully planned. Ensure that the control cabinet has sufficient space to accommodate the module and any related wiring. The control cabinet should also be properly grounded to prevent electrical interference and ensure the safety of the entire system. In addition, maintain appropriate gaps around the module to ensure proper ventilation. Overheating can significantly affect the performance and lifespan of modules, therefore proper air circulation is crucial.

In terms of maintenance, it is recommended to conduct regular visual inspections. Check for any signs of physical damage, such as cracks or loose connections. Monitor the status indicator lights of the monitoring module to identify any potential issues as early as possible. Signal diagnosis should be conducted regularly to ensure the accuracy of transmitted and received data. GE typically provides software tools for these diagnostics, which can be used to quickly identify and resolve any communication or signal related issues. In addition, keep the firmware of the module updated. GE will regularly release firmware updates to improve performance, fix errors, and enhance security. Updating firmware helps ensure that GE WEA13-13 2508-21001 maintains optimal performance over time.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626