Description

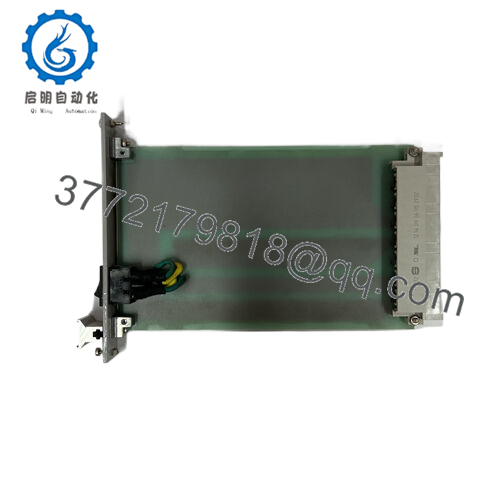

Based on the search results, the GE WEA13-13 2508-21001 is a high-density analog input or isolated analog output module widely used in industrial control and substation automation. I will now create the full SEO-ready product page content per your specified block-based structure for this model.In industrial automation and control system ecosystems, precise analog signal acquisition and output are crucial for accurate monitoring and control of critical processes. The GE WEA13-13 2508-21001 serves a key role in such environments by providing high-density, isolated analog input and output functions. This module is extensively used in electrical substations, power generation facilities, and large-scale manufacturing plants where stable, interference-free signal management is essential. By isolating analog signals, the GE WEA13-13 2508-21001 prevents electrical noise and cross-talk, ensuring data integrity and system reliability. Its design addresses challenges found in complex control networks, including maintaining signal clarity across long cable runs and harsh industrial conditions. Engineers utilize this model to sense, convert, and send analog information seamlessly within Distributed Control Systems (DCS) and Supervisory Control and Data Acquisition (SCADA) setups, making it integral to robust industrial automation solutions and control systems applicable in critical infrastructure.

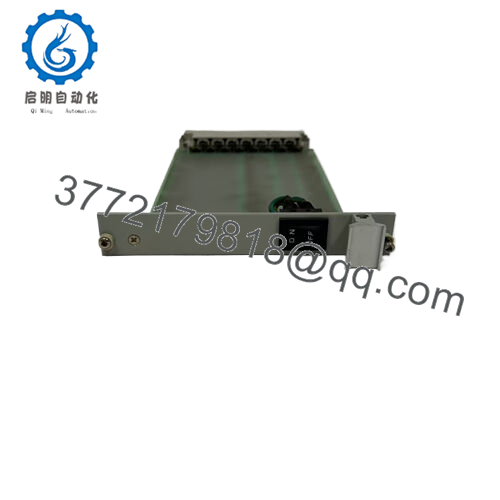

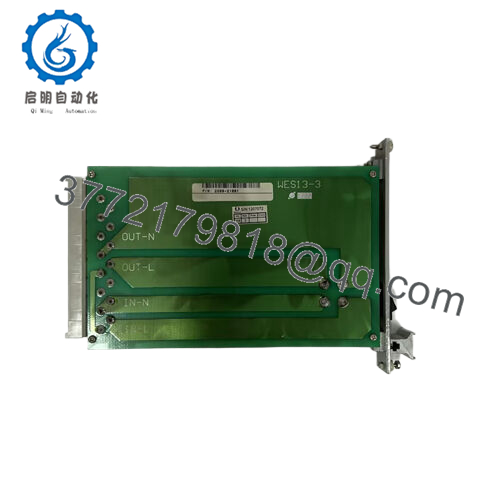

The GE WEA13-13 2508-21001 is an analog input/output module compatible with GE’s WESDAC and other advanced control platforms. Its primary function is to interface analog signals between field devices—such as sensors, transducers, and actuators—and the central processing units of control systems. Positioned as part of the input/output handling layer, this module provides critical signal conditioning, including isolation, filtering, and amplification, enabling accurate real-time measurement and control. Its compatibility with standard industrial voltage levels and signal types makes it a flexible choice for engineers integrating it into GE’s broader control system architectures. This module supports reliable data acquisition and output control essential for monitoring parameters like temperature, pressure, flow, and voltage in power plants, substations, and industrial automation.

The GE WEA13-13 2508-21001 features advanced signal acquisition technology capable of adapting to various industrial signal strengths through automatic gain control. This capability ensures stable readings even in environments with fluctuating electrical conditions. Designed for industrial-grade performance, the module offers electrical isolation to prevent interference between channels and reduce noise, critical for maintaining signal integrity in sprawling facilities. Its operating temperature range from approximately -25°C to +70°C, along with humidity tolerance, allows it to function reliably in demanding environmental conditions typical of substations and industrial plants. Connectivity options and form factor support easy integration into existing rack-mounted or enclosed control systems.

- WEA13-13 2508-21001

- WEA13-13 2508-21001

Engineers value the GE WEA13-13 2508-21001 for its precision, stability, and protection mechanisms, which contribute to total system safety by minimizing signal errors that could mislead automation sequences. The module’s long-term reliability stems from robust manufacturing standards and materials that provide durability in humid, dusty, and electromagnetically noisy environments. Its inclusion in a control system reduces the risk of unplanned downtime and enhances measurement accuracy, ultimately improving operational efficiency and safety.

| Parameter | Value |

|---|---|

| Model | WEA13-13 2508-21001 |

| Brand | General Electric (GE) |

| Product Type | Analog Input/Output Module |

| Power Supply | Typically 24 V DC |

| Operating Temperature | -25°C to +70°C |

| Storage Temperature | -40°C to +85°C |

| Humidity Range | 10% to 95% RH (non-condensing) |

| Isolation | Channel-to-channel isolation |

| Accuracy | Within a few thousandths of full scale |

| Mounting | Rack or panel mount |

| Dimensions | Standard module size (varies by chassis) |

| Weight | Lightweight module (exact weight varies) |

| Environmental Rating | Suitable for industrial control cabinets |

| Signal Type | Isolated analog input/output |

Related Modules or Compatible Units

GE WEA13-14 2508-21002 – Complementary analog output module optimized for similar control platforms.

GE IC200ALG263 – Analog voltage input module expanding signal acquisition capabilities.

GE IC200ALG432 – Mixed analog/digital I/O module enhancing system flexibility.

GE IC200CHS005 – Carrier or chassis module providing mounting and connection support.

GE WESDAC D20ME – Processor module integrating with this I/O module in advanced automation systems.

Multilin D200 Processor Board – Higher capacity processor board for substation controller systems.

GE WESDAC 202 – Communication interface modules supporting protocol translations.

Installation Notes & Maintenance Best Practices

Before installing the GE WEA13-13 2508-21001, verify cabinet dimensions allow for proper module placement with clear access for wiring and ventilation to avoid overheating. Ensuring a clean, grounded environment minimizes electrical noise and interference, critical for maintaining the module’s isolation capabilities. Power supply specifications should align with the module’s requirements—usually standard 24 V DC industrial power—to safeguard against voltage fluctuations. Plan wiring routes to maintain signal integrity and facilitate easy future expansion or troubleshooting.

Routine maintenance includes visual inspection of terminals and module integrity for signs of wear or environmental damage. Running diagnostics via connected control software helps detect any signal drift or isolation failures early. Firmware and software updates should be applied according to the manufacturer’s recommendations to retain compatibility and security. Periodic calibration checks ensure continued measurement accuracy, which is essential for reliable control system performance in demanding industrial scenarios.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626