Description

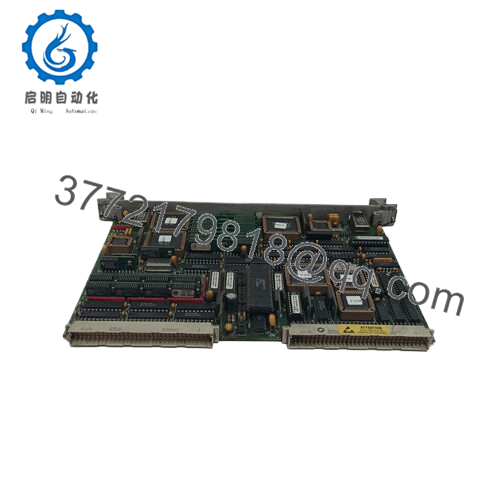

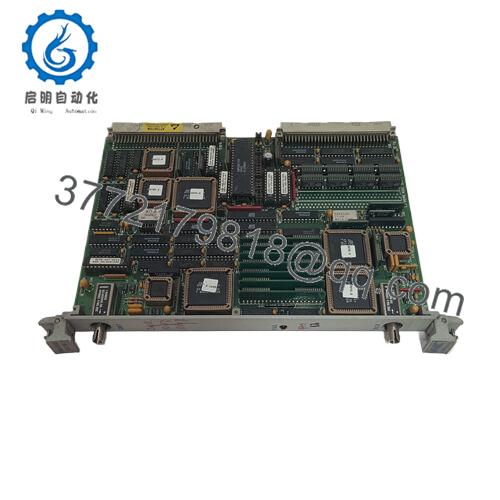

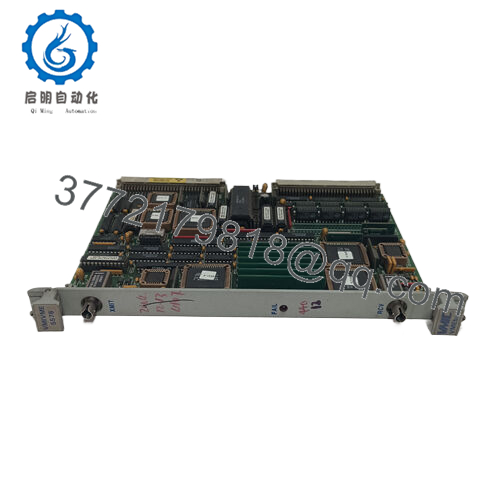

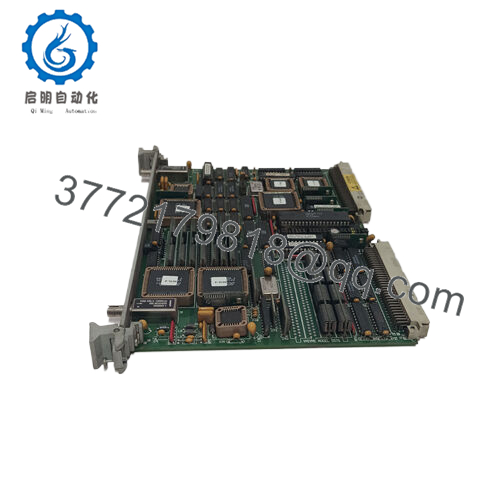

The GE VMIVME5576 is a high-performance fiber optic reflective memory interface module designed for use in VMEbus-based industrial automation and control systems, particularly within GE’s Speedtronic turbine control platforms. This module excels in real-time data sharing and synchronization across distributed control nodes, enhancing system reliability and performance in critical applications such as power generation, turbine control, and complex manufacturing processes. The VMIVME5576 supports high-speed fiber optic communication, ensuring ultra-fast and deterministic memory updates which are essential for seamless coordination and control in large-scale industrial environments.

The GE VMIVME5576 operates at a fiber optic serial data rate of 170 Mbaud, supporting node-to-node spacing of up to 2,000 meters and scalable to networks comprising up to 256 nodes, making it highly suitable for extensive distributed control networks. It features configurable onboard SRAM memory ranging from 256 Kbyte to 1 Mbyte for flexible data handling depending on application needs. The module’s design accommodates a maximum data transfer rate of up to 6.2 Mbyte per second, enabling the rapid exchange of control data across the network. It uses a fiber-optic network interface for robust and electromagnetic interference-immune communication, critical in noisy industrial electrical environments. The instrument’s compliance with stringent industrial standards ensures durability and operational stability under demanding conditions.

- VMIVME5576

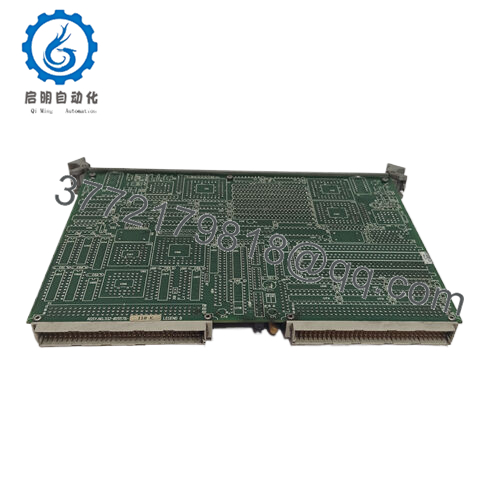

Physically, the VMIVME5576 conforms to the VME 6U form factor, fitting seamlessly into standard VME racks and chassis. It supports an operating temperature range suitable for industrial applications, ensuring reliable performance over extended periods. The module integrates with GE’s Speedtronic control platforms and other VME-compatible equipment, facilitating enhanced data replication and synchronization necessary for high-availability control systems. Its robust construction and high-speed reflective memory functionalities make it a vital component in power plant turbine control and other mission-critical automation systems.

| Parameter | Value |

|---|---|

| Model | VMIVME5576 |

| Brand | General Electric (GE) |

| Product Type | Fiber Optic Reflective Memory Interface Module |

| Data Rate | 170 Mbaud serial fiber optic |

| Onboard Memory | 256 Kbyte to 1 Mbyte SRAM |

| Max Node Spacing | Up to 2,000 meters |

| Max Network Nodes | Up to 256 |

| Max Data Transfer Rate | 6.2 Mbyte/s |

| Interface | Fiber Optic |

| Form Factor | VME 6U Standard |

| Operating Temperature | Industrial standard range |

| Application | Real-time data sharing in distributed control |

Related modules compatible with the VMIVME5576 include:

VMIVME-5530S – Analog input/output modules for complementary signal processing.

VMIVME-5577 – Sibling reflective memory module with variant memory configurations.

VMIVME-7768 – VME single board computer module to manage control system processing.

VMIVME-7698 – High-channel count digital input board used alongside reflective memory modules.

VMICPMC-5565 – PMC mezzanine cards for expanded communication or I/O.

Installation of the GE VMIVME5576 requires a standard VMEbus chassis with appropriate power and cooling. Fiber optic cables selected must comply with module specifications for distance and type (multimode or single mode). Proper grounding and electromagnetic interference (EMI) protection are critical to maintain signal integrity. Regular maintenance includes inspecting fiber connections, cleaning interfaces, and updating firmware as per GE’s recommendations.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626