Description

In the demanding landscape of industrial automation, capturing discrete events from field devices—like switch states, proximity sensor triggers, or emergency stop signals—without distortion or delay is crucial for maintaining process control integrity. Envision a conveyor system in a steel mill where a misread limit switch cascades into jammed rollers, halting lines and risking mechanical damage, or a chemical batch plant where overlooked valve positions lead to overpressure alarms that trigger unnecessary shutdowns. These pain points are all too familiar in environments requiring high reliability for digital I/O signals, from rugged factory floors to remote SCADA outposts, where electrical noise from drives or welders corrupts inputs, forcing engineers into endless debouncing hacks or redundant wiring schemes that inflate costs and complexity.

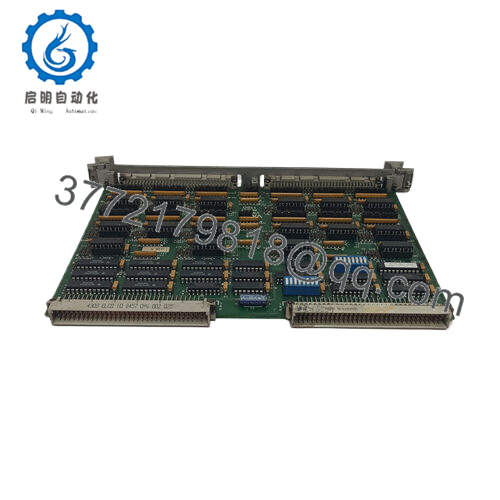

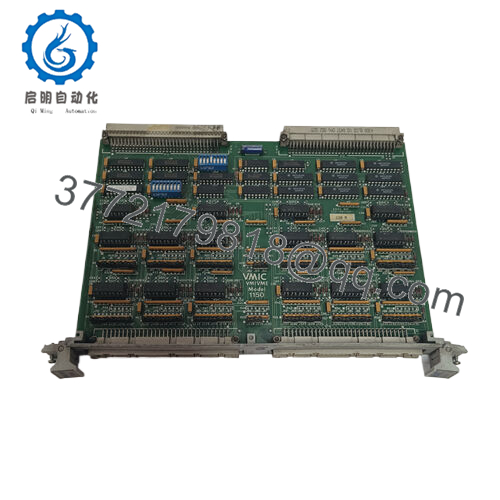

- VMIVME1150

Here, the GE VMIVME1150 emerges as a high-density digital input module, tailored to deliver optically isolated, rock-solid state detection for up to 64 channels in VMEbus architectures. It directly confronts the need for modular integration in legacy or hybrid systems, shielding against common-mode voltages up to 500V while latching transients to preserve data fidelity during high-speed scans—essential when upgrading discrete I/O in DCS expansions or embedding into real-time test rigs. For teams navigating EMI-saturated zones or scaling sensor arrays without ballooning chassis footprints, the GE VMIVME1150 proves indispensable, transforming erratic edge triggers into dependable process variables that feed control logic without false positives.

The fallout from unreliable digital inputs extends beyond immediate trips: it undermines trend analysis in historians, erodes confidence in safety PLC interlocks, and complicates fault tracing in distributed automation networks. With its change-of-state interrupts and front-panel diagnostics, the GE VMIVME1150 empowers precise event synchronization, enabling tighter coordination between field layers and supervisory platforms—think sub-millisecond polling that anticipates bottlenecks before they disrupt throughput. In essence, it’s the steadfast buffer that elevates industrial automation from fragile patchwork to cohesive, high-reliability orchestration, where every bit flip counts toward seamless operations.

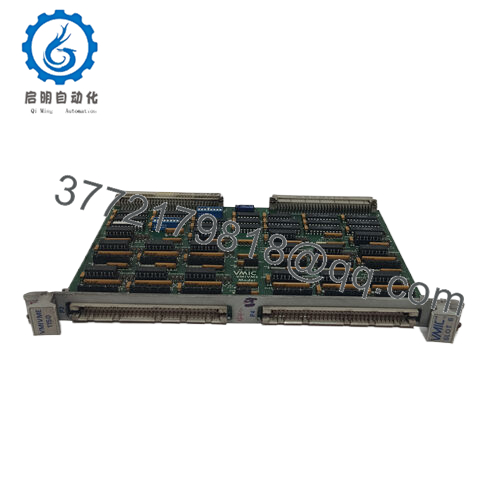

Slotting the GE VMIVME1150 into your VME ecosystem is akin to bolstering the chassis with a vigilant input aggregator—it plugs into a standard VME64 slot as a single-width board, drawing power from the backplane while exposing 64 optically coupled inputs via two 100-pin connectors for field wiring to dry contacts or TTL-level sensors. Nestled in the I/O stratum of your stack, it debounces signals on the fly (configurable from 0.5 to 50 ms) and asserts interrupts to the VMEbus arbiter, queuing state vectors for rapid retrieval by host CPUs like GE’s Pentium-based SBCs or third-party RTOS kernels, all while supporting block reads for efficient bandwidth use in multi-slot configurations.

Operationally, it thrives on simplicity: connect your discrete sources—say, solenoid feedbacks or photoeye outputs—to the screw terminals, then access the dual-ported RAM buffer through A24/D32 space for near-real-time mirroring, ensuring no data staleness in high-throughput loops. This module doesn’t impose; it accommodates, with jumper-selectable input thresholds and built-in surge protection that interfaces cleanly with backplane systems like VMIVME-7800 carriers, fostering redundancy via mirrored boards for hot-standby failover. Tie it to protocols through the host’s serial or Ethernet ports, and it feeds sanitized bitmaps into Modbus or custom APIs, bridging raw field pulses to polished SCADA visuals. In the broader automation hierarchy, the GE VMIVME1150 anchors the sensor-facing edge, filtering noise to deliver crisp telemetry that sharpens decision-making without taxing upstream resources—ideal for retrofits where VME longevity meets modern IIoT aspirations.

| Specification | Details |

|---|---|

| Model Number | VMIVME1150 |

| Brand | GE Fanuc VMIC |

| Type | 64-Channel Optically Isolated Digital Input Module |

| Input Voltage | 5 V DC (backplane) |

| Operating Temp Range | 0°C to +70°C |

| Mounting Style | VMEbus Single-Slot |

| Dimensions | 233 x 100 mm (VME form factor) |

| Weight | 0.4 kg |

| Interface/Bus | VME64 (A24/A32/D08/D16/D32) |

| Compliance | VITA 1-1994, CE, FCC Class A |

| Supported Protocols | VMEbus Interrupts, Dual-Port RAM |

| Typical Power Draw | 4 W |

Embracing the GE VMIVME1150 instills a core of unyielding reliability in your digital front end, where optical isolation decouples field grounds from the bus, preventing the voltage spikes that fry lesser boards and ensuring state reads remain accurate through power glitches—translating to fewer spurious interlocks that could otherwise stall production lines for hours. This engineered fortitude means your process control stays on rails, with debounced edges that align perfectly with timing-critical sequences, cutting variability in automated sorts or fills and preserving yield in precision ops.

Consistency in performance shines through its FIFO-like buffering, which smooths bursty inputs from vibrating machinery, allowing control algorithms to operate on settled data rather than chasing transients—a boon for maintenance teams who no longer sift through oscilloscope dumps for validation. It trims engineering overhead by exposing health via status registers, so routine polls reveal stuck channels early, streamlining diagnostics in vast I/O grids and slashing mean-time-to-isolate from days to diagnostics. Over the long arc, this module ensures enduring performance with conformal coatings that resist dust ingress, holding calibration across thermal swings without the drift that demands annual recalibrations.

Integration’s subtle power lies in its VME-native footprint, which drops into existing crates without reconfiguration, accelerating deployments by weeks and easing the blend of legacy sensors with edge analytics—your squad reallocates from hardware wrangling to optimizing loops. For sites pushing toward predictive regimes, the GE VMIVME1150 lays the groundwork, its interrupt-driven architecture feeding clean event streams to ML models for anomaly spotting, ultimately dialing down total cost of ownership by preempting failures that cascade into lost shifts.

In semiconductor fabs, the GE VMIVME1150 aggregates tool status from wafer handlers and gas cabinets, where process control environments mandate high reliability for cleanroom interlocks—its 64 channels consolidate alarms from vacuum pumps, ensuring critical system uptime amid ESD-prone airflows and rapid cycle times that brook no input lag. Racked in VME enclosures near lithography bays, it captures state shifts with isolated fidelity, bolstering fault-tolerant sequences that keep fab yields humming.

Aerospace test stands harness it for engine rig monitoring, channeling discrete signals from thrust sensors and fuel valves in harsh, high-vibration conditions—deployed in ruggedized chassis, the module’s surge tolerance maintains data integrity during shock tests, supporting continuous uptime for validation runs where a single missed trigger voids certification data. In rail signaling yards, it processes trackside occupancy from inductive loops, delivering high reliability in EMI-heavy switchyards to enforce safe routing in process control loops tied to dispatch systems, all while withstanding outdoor temp extremes.

VMIVME1160 – Counterpart output module for balanced digital actuation in VME setups

VMIVME-1182 – 32-channel variant with enhanced ESD protection for field-heavy apps

VMIVME-311x – Analog input sibling for hybrid signal processing in sensor fusion

VMIVME-7698 – PMC carrier adapter to extend the board into mezzanine expansions

VMIVME-5550 – Reflective memory node for real-time data sharing across chassis

VMIVME-7807 – VMEbus SBC host for standalone integration with the input module

VMIVME-6016 – High-speed serial interface add-on for protocol tunneling

As you gear up to seat the GE VMIVME1150 in your VME frame, prioritize a slot audit—confirm A24 space availability to avoid address overlaps, and measure backplane current headroom since full-channel loading can nudge draws toward 5W peaks; a quick multimeter tap on P1/J1 pins verifies clean +5V delivery. If sourcing from mixed-vendor crates, cross-check VME revision compliance via the utility software, and pre-populate jumpers for debounce intervals matching your scan rates to sidestep initial tuning loops. For multidrop fields, label wiring harnesses against the pinout diagram, and dry-run a continuity test benchside to catch open circuits before enclosure seal-up.

In service, upkeep revolves around pragmatic spot-checks: fortnightly, script a host query to toggle test inputs and log debounce efficacy, flagging any hysteresis creep that might signal optic wear, while visual scans of edge connectors every quarter catch oxidation in humid depots—a soft cloth and IPA wipe restores contact without teardown. GE outlines annual full-load soaks, injecting simulated pulses across all 64 bits to benchmark interrupt latency against factory specs, ideally with a logic analyzer for waveform correlation. In networked VME arrays, enable the board’s ID register for inventory sweeps during startups, and for distant installs, remote-access the dual-port window via Ethernet gateways to harvest status without boots. This steady vigilance sustains its edge without overcommitting your ops tempo.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626