Description

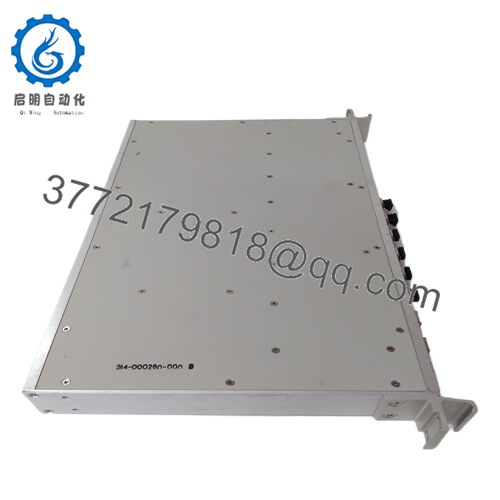

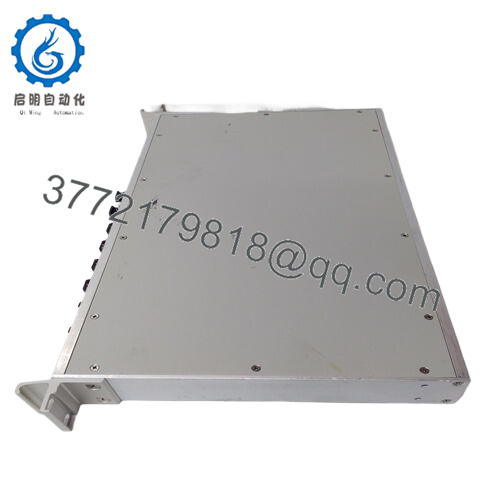

Product Model: GE VMIAC-5595-208

- Product Brand: General Electric (GE)

- Product Series: GE VME Industrial Computing Series

- Product Features:

- High-performance VMEbus interface for industrial automation

- Rugged design for continuous and demanding environments

- Compatible with GE’s industrial computing systems

- Long lifecycle support with proven reliability

Applications & Industry Context

In heavy industries where uptime is not just important but mission critical, control modules like the GE VMIAC-5595-208 provide the backbone for reliable automation. This module is often found in environments where high-speed data exchange between processors and field devices is necessary, such as in power generation facilities, advanced manufacturing plants, and transportation infrastructure systems.

The module’s design reflects the growing need for rugged computing that can survive dust, vibration, temperature fluctuations, and electrical noise. For example, in turbine control systems, operators rely on consistent data communication between sensors, actuators, and supervisory controllers. The GE VMIAC-5595-208 ensures that this information moves quickly and reliably across the VMEbus, minimizing latency and reducing risk of downtime.

In rail and aerospace testing facilities, VME interface modules such as this one are valued for their ability to synchronize multiple subsystems. They support simulation equipment, test benches, and monitoring setups that demand consistent throughput. Oil and gas companies also deploy these modules offshore and in refineries, where system stability directly ties into operational safety.

VMIACC-5595-208

Product Role & System Fit

The GE VMIAC-5595-208 is a VME interface board designed to act as a bridge within GE’s automation and computing architecture. It plays a vital role in managing data flow between CPUs and other VMEbus devices. By doing so, it ensures compatibility across distributed industrial control systems, allowing engineers to scale and reconfigure applications without costly rewiring or downtime.

This module integrates seamlessly with existing GE automation platforms, offering backward compatibility with earlier generations of GE VME modules. Engineers appreciate its plug-and-play setup, which reduces the learning curve during system expansion. In large distributed control systems (DCS), it often supports functions like real-time monitoring, diagnostics, and redundancy management, making it essential for operators who cannot afford communication bottlenecks.

Whether deployed in a new installation or as a replacement unit, the GE VMIAC-5595-208 supports modular design principles, allowing customers to extend the useful life of their existing GE infrastructure while adopting newer technologies incrementally.

Technical Features & Benefits

What sets the GE VMIAC-5595-208 apart is its engineering focus on performance and durability. Built around the VMEbus standard, it delivers consistent throughput and ensures synchronization across multiple I/O and processing units.

Key benefits include:

- Robust Data Handling: High-bandwidth design ensures minimal data loss even under heavy system loads.

- Industrial Durability: Shock-resistant and temperature-tolerant construction makes it suitable for extreme environments.

- Flexible Integration: Compatible with other GE VME cards, reducing integration headaches in complex systems.

- Lifecycle Support: GE has designed the module for long-term use, offering dependable operation over years of continuous duty.

This combination of speed, reliability, and compatibility gives operators confidence that their automation systems will not just function but thrive under demanding workloads.

Technical Specifications

| Specification | Value |

|---|---|

| Model Number | GE VMIAC-5595-208 |

| Brand | General Electric (GE) |

| Series | VME Industrial Computing Series |

| Form Factor | VMEbus Module |

| Function | Interface and control card |

| Operating Voltage | Standard VME power requirements |

| Communication Bus | VMEbus architecture |

| Cooling Method | Convection or forced-air (system dependent) |

| Dimensions | Standard VME 6U size |

| Operating Environment | Industrial-grade, wide temperature tolerance |

| Mounting | Rack-mounted in VME chassis |

| Compatibility | GE VME series controllers and processors |

Related Models

- GE VMIACC-5596-208 – Enhanced processing version with extended I/O support

- GE VME-7750 – High-performance CPU card for demanding VMEbus applications

- GE VMIVME-4140 – Analog output board for industrial control integration

- GE VMIVME-5565 – Reflective memory card for high-speed data sharing

- GE VMIVME-7452 – Display controller for visualization systems

- GE VMIVME-7807RC – Rugged embedded computing board for harsh environments

- GE VMIACC-5595-212 – Variant offering expanded communication features

Installation & Maintenance Insights

Installing the GE VMIAC-5595-208 requires only standard VME chassis access and proper grounding, but attention to environmental conditions pays dividends in long-term reliability. Engineers typically verify airflow within the rack and confirm that no dust accumulation blocks ventilation paths. While the module itself is built to endure rugged use, periodic visual inspection helps catch issues such as connector wear or loose cabling.

Firmware and system configuration updates are often managed through GE’s integrated tools, making ongoing maintenance straightforward. In the field, technicians value the hot-swap capability that allows quick module replacement with minimal downtime. With proper care, the GE VMIAC-5595-208 can operate for many years before requiring significant servicing.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626