Description

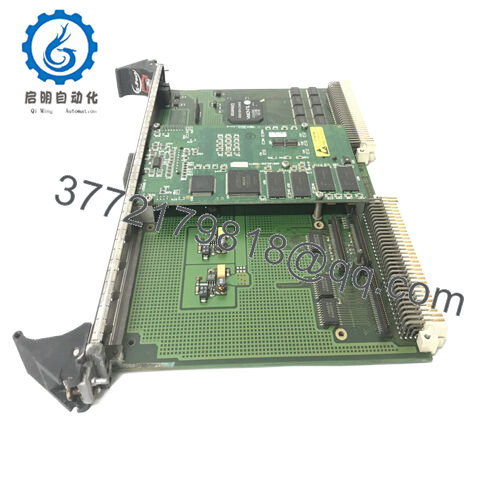

GE VME-PCM-CADDY is a high-performance VMEbus carrier board designed specifically for carrying PMC (PCI mezzanine card) modules. It is a key component of the VME based control system architecture, providing a platform for integrating different PMC modules to meet diverse application requirements.

VME-PMC-CADDY

As part of GE’s extensive portfolio of industrial and embedded computing solutions, GE VME-PCM-CADDY aims to provide reliable and efficient interfaces between VMEbus and PMC modules. It complies with the VME64 standard, ensuring compatibility with a wide range of VME based systems.

VME-PMC-CADDY

Main features and advantages:

From a performance perspective, GE VME-PCM-CADDY provides high-speed data transfer rates. It has a data width of up to 32 bits and 32 address signals on VMEbus, enabling fast transfer of large amounts of data between PMC modules and the rest of the VME based system. This is crucial for applications that require real-time data processing, such as industrial control systems that need to make instantaneous decisions based on incoming sensor data.

In terms of hardware design, the carrier board is sturdy and durable. It can withstand harsh environmental conditions, including temperature changes, vibrations, and electromagnetic interference. Two 160 pin VG connectors compatible with VME64 expansion provide secure and reliable connections for VMEbus. The compact size of the carrier board makes it suitable for installation in narrow spaces, which is common in many industrial and aerospace applications.

Compatibility is one of its main advantages. It is designed to seamlessly collaborate with various PMC modules, regardless of the manufacturer. This allows users to choose the PMC module that is most suitable for their specific application and easily integrate it into the VME based system. In addition, it supports seven interrupt request lines, which can be used to handle asynchronous events in the system, further enhancing its flexibility and responsiveness.

Long term reliability is also a key characteristic. GEVME-PCM-CADDY has undergone rigorous testing to ensure continuous operation in harsh environments. It has built-in diagnostic functions that can detect and report any potential issues, enabling proactive maintenance. The software drivers and documentation provided by GE make it easier for users to configure and maintain the carrier board, ensuring its long-term performance.

VME-PMC-CADDY

Technical specifications:

Model GE VME-PCM-CADDY

Brand GE

The type of VMEbus carrier board used for PMC modules

Compatibility with VME64 standard, supporting a wide range of PMC modules

Data width up to 32 bits

32 address signals on VMEbus

7 interrupt request lines

Two 160 pin VG connectors that comply with IEC 603-xx and VME64 extensions

The module can accommodate up to two single size PMC modules or one dual size module

Working temperature range -20 ° C to+70 ° C

Compliant with IEEE P1386 and IEEE 1014 Rev. D standards (if applicable)

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

VME-PMC-CADDY

Application areas:

In the field of industrial automation, factories rely on it to enhance the connectivity and performance of their production lines. For example, in large automobile manufacturing plants, GE VME-PCM-CADDY can be used to integrate multiple programmable logic controllers (PLCs), sensors, and actuators. It can achieve high-speed data transmission between these components, ensuring the smooth operation of the assembly line. In chemical processing plants, it helps manage control systems for temperature, pressure, and flow. By promoting seamless communication between different modules of the control system, it ensures that chemical reactions occur under optimal conditions, minimizing waste and improving production efficiency to the greatest extent possible.

In the military and aerospace fields, reliability and performance cannot be compromised. The military command center uses GE VME-PCM-CADDY to integrate various communication and surveillance systems. It is capable of processing large amounts of data from radar systems, satellite communication links, and unmanned aerial vehicle (UAV) control stations, enabling rapid decision-making on the battlefield. In the aerospace field, it is used in aircraft avionics systems to connect different flight control modules, navigation systems, and communication equipment. Its ability to operate in harsh environments such as extreme temperatures and high vibrations makes it an ideal choice for these applications.

Medical imaging facilities also benefit from GE VME-PCM-CADDY. In hospitals, it can be used to integrate different imaging modes such as magnetic resonance imaging (MRI), computed tomography (CT), and ultrasound systems. By achieving seamless data transmission between these devices and central data storage and processing units, it helps to provide accurate and timely medical diagnosis.

Related products:

GE VME-PMC CADDY -32P2- This is an option for GE VME-PMC CADDY that provides an alternative P2 pin assignment. When specific PMC I/O signal connections require different configurations, it can be used to provide more flexibility for system design.

PMC based communication modules (such as modules with Ethernet, RS-232, or RS-485 interfaces) – These modules can be plugged into GE VME-PMC CADDY to enhance the communication capabilities of VME based systems. For example, an Ethernet enabled PMC module can be used to connect the system to a local network for remote monitoring and control.

Data Collection PMC Module – When integrated with GE VME-PMC CADDY, these modules can be used to collect data from various sensors in industrial, aerospace, or medical applications. They can measure parameters such as temperature, pressure, and voltage, and transmit the data to the VME based system for further processing.

Signal Processing PMC Module – These modules can be used in conjunction with GE VME-PMC CADDY to perform tasks such as signal filtering, amplification, and modulation. In industrial control systems, a signal processing PMC module can be used to condition sensor signals before they are processed by the main controller.

GE VME based power modules – These modules are crucial for powering GE VME-PMC CADDY and connected PMC modules. They ensure a stable and reliable power supply, which is crucial for the normal operation of the system, especially in applications where power fluctuations may cause system failures.

GE VME-PMC CADDY related software libraries – These software libraries provided by GE can be used to simplify the programming and configuration of GE VME-PMC CADDY and connected PMC modules. They provide pre written functions and routines that can be used to control hardware and reduce engineers’ development time.

GE VME-PMC CADDY compatible enclosures – These enclosures are designed to accommodate GE VME-PMC CADDY and connected modules. They provide physical protection and help organize components, making the entire system more compact and easy to maintain.

Installation and maintenance:

Before installing GE VME-PCM-CADDY., it is necessary to ensure that the installation environment meets the required specifications. The VMEbus system installed should be properly grounded to prevent electrical interference. The temperature and humidity in the installation area should be within the specified working range of the carrier board to ensure optimal performance and lifespan.

When installing the carrier board, be careful to avoid electrostatic discharge, which may damage sensitive components. Ensure that the PMC module is correctly inserted into the slot of GEVME-PCM-CADDYand the connector is securely fixed. It is also recommended to check the compatibility between the PMC module and GE VME-PCM-CADDY. before installation to avoid any potential issues.

For maintenance, it is recommended to conduct regular visual inspections. Check for any signs of physical damage, such as bent pins, broken components, or loose connections. These issues can usually be detected early through visual inspection to prevent more serious problems from arising. Regularly update the software drivers provided by GE to ensure that the carrier board runs the latest performance enhancements and error fixes. In addition, running diagnostic tests using built-in diagnostic tools (if available) can help identify any potential hardware or software issues. If any issues are detected, please refer to the documentation provided by GE or contact their technical support for further assistance.

Other GE product models:

GE HE693THM888K

GE IS420EWSBH3A

GE IS200TREAS1A

GE IC695CPE305

GE F650BFBF1G0HI6E

GE VMIVME-5565-110000

GE IC695CPU315-CD

GE IC695NKT002

GE IC695CPU315-CD

GE IS200TDBTH6ABC

GE IC800SSI228RD2

GE TKMA3Y1200

GE IS210MACCH1AKH

GE IS210BPPBH2CAA

GE IS210MACCH1AGG

GE IS200AEPCH1BAA

GE IS200WEMAH1AEA

GE IS200AEPAH1AHD

GE IS200WETAH1AEC

GE VMIVME-5565-010000 332-015565-010000 P

GE IC695ALG508-AA

GE DS200CPCAG1ABB

GE DS3800HFPB1F1E

GE DS3800NB1A

GE IC695ALG508

GE IC695ALG508

GE MIVII1000E00HI00

GE IC758CSWC19PCX512

GE XMTC-6C-11

GE WPX-08 WE3DNQGQEXBBXCX

GE 750-P5-G5-S5-HI-A20-R-E

GE 469P5HIA20EH

GE IC694PWR330

GE IC200ALG262

GE CK10CE300

GE IC755CBW07CDA

GE IS220PTURH1B

GE IS220PTURH1A

GE IS420UCSBS1A

GE IS200TDBSH6ABC

GE IS200STAIH1ABB

GE IS200SRTDH1ABB

GE IS420ESWB3HA

GE IS200JPDFG1A

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626