Description

Real-World Use & Application Scenarios

In the demanding landscape of industrial automation, aerospace, and energy management, the GE V7768-312001 serves as a pivotal computing solution engineered to meet high-performance requirements. This versatile module is primarily used in complex control systems that require reliable, fast processing and extensive I/O support. Industries such as manufacturing, power generation, oil and gas, and aerospace heavily depend on such modules to drive precise control and real-time monitoring of critical operations. For example, in manufacturing plants, the GE V7768-312001 facilitates communication between PLCs, sensors, and actuators, enabling sophisticated automation workflows that maximize production efficiency and safety. It is also applicable in control systems where resilience to vibration, electrical noise, and temperature variations is mandatory, reflecting its industrial-grade design. Beyond automation, this product finds use in aerospace systems, including navigation and communication modules, where low latency and high reliability are essential. Through its ability to handle complex algorithms and multitasking demands, the GE V7768-312001 supports a wide range of technical tasks, including data processing, fault diagnosis, and system diagnostics, making it a keystone component in environments where uptime and precision are non-negotiable.

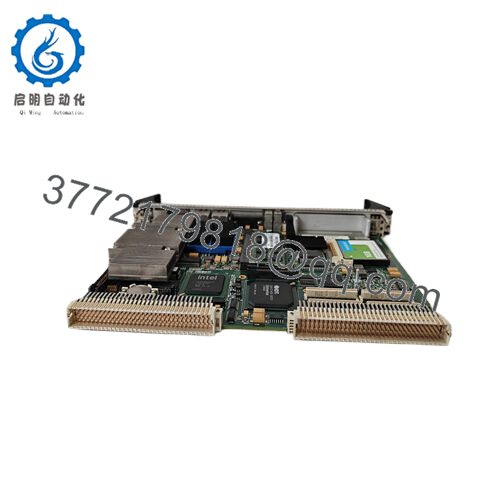

Product Introduction & Positioning

The GE V7768-312001 is a VME single-board computer (SBC) designed for integration within industrial control systems and embedded applications. Equipped with a powerful Intel Core 2 Duo processor clocked at 2.16 GHz, this board handles multitasking and compute-intensive processes essential for modern industrial automation. It supports up to 2 GB of DDR2 SDRAM and includes a PCI-X PMC expansion site, allowing for customized I/O capabilities via add-on boards. As a control system module, it acts as the computational core that processes input signals, runs control algorithms, and communicates with peripheral devices and networks. It is compatible with multiple operating systems such as Windows XP, VxWorks, and Linux, offering flexibility for diverse application environments. The GE V7768-312001 fits seamlessly into architectures requiring distributed processing, real-time control, and high data throughput, making it highly valuable for engineers and integrators aiming to build scalable, robust control platforms.

- V7768-312001

- V7768-312001

Key Technical Features & Functional Benefits

The GE V7768-312001 stands out with its robust computing performance, powered by the Intel Core 2 Duo processor that delivers up to 2.16 GHz speed. This enables efficient multitasking and high-speed execution of complex control and data processing applications, essential for industrial usage. Its support for up to 2 GB DDR2 SDRAM ensures smooth memory-intensive operations, contributing to overall responsiveness and system stability.

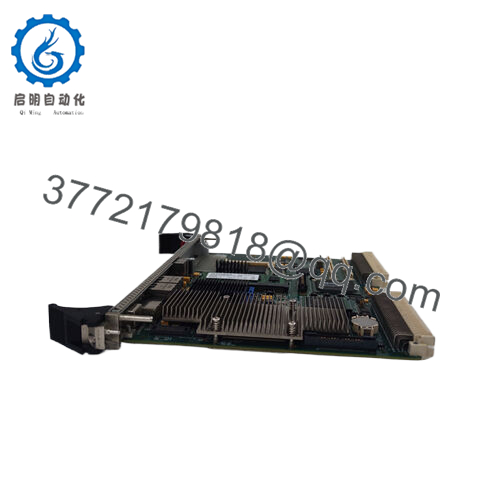

The hardware design is industrial-grade and rugged, supporting operating temperatures from -20°C to +60°C and offering resilience against vibration and electromagnetic interference. The module’s 6U VME form factor and dual-slot design provide ample space for extensive I/O integration and make it suitable for installation in standard VME chassis. The inclusion of a PCI-X PMC expansion site enables flexible hardware customization, allowing users to tailor I/O connections to precise application needs without redesigning the entire system.

In terms of connectivity, the GE V7768-312001 features diverse interfaces, including USB ports, serial communication ports, and SATA storage options, facilitating integration with peripheral devices and networks. This broad compatibility supports enhanced data acquisition, storage, and communication capabilities. Furthermore, the product’s long-term reliability is supported by solid-state storage and thermal management features, ensuring consistent operation even in challenging industrial environments.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | V7768-312001 |

| Brand | GE (General Electric) |

| Product Type | VME Single-Board Computer (SBC) |

| Processor | Intel Core 2 Duo, 2.16 GHz |

| Maximum Memory | Up to 2 GB DDR2 SDRAM |

| Storage | Up to 8 GB CompactFlash |

| Expansion Capability | 1 x PCI-X PMC expansion site |

| Operating Temperature | -20°C to +60°C |

| Form Factor | VME 6U dual-slot |

| Interfaces | USB 2.0, SATA, Serial ports |

| Supported OS | Windows XP, VxWorks, Linux |

| Cooling | Passive |

| Ruggedization Features | Anti-vibration, Anti-interference |

Related Modules or Compatible Units

V7769-312002 – A sibling model featuring an enhanced Intel Core 2 Duo for higher processing power and expanded I/O.

GE VMIVME-7750 – VME-based processor board compatible for system upgrades and extended applications.

V7768-320001 – An advanced variant with additional Gigabit Ethernet and USB interfaces for networked environments.

DS200DCFBG1BJB – Complementary data communication module for industrial control networks.

IC698CPE040-JP – GE’s programmable automation controller that pairs well with the V7768 series for full control system solutions.

3BHB013088R0001 – ABB compatible I/O expansion module used with GE systems for mixed-brand automation architectures.

MVME5500-0161 – Motorola VME SBC offering legacy system integration options.

Installation Notes & Maintenance Best Practices

When preparing to install the GE V7768-312001, ensure that the VME chassis selected supports 6U dual-slot boards with sufficient cooling and ventilation, as the module relies on passive cooling. Grounding and shielding of the cabinet should conform to industrial standards to prevent electromagnetic interference that could impair signal quality. Adequate spacing must be allocated for cabling and potential expansion boards, as well as to ease future maintenance access. Confirm that power supply voltage and current ratings match the specifications to avoid hardware damage.

For maintenance, regularly monitor module status via diagnostic LEDs and system software alerts to anticipate potential faults. Visual inspection of connectors for dust and corrosion should occur in routine maintenance cycles. Firmware updates and software patches should be executed during planned downtimes using manufacturer guidelines, ensuring operational continuity. Also, verify that peripheral expansions are seated properly to avoid communication errors. Implementing a schedule of these best practices will help optimize the lifespan and performance of the GE V7768-312001 within industrial environments.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626