Description

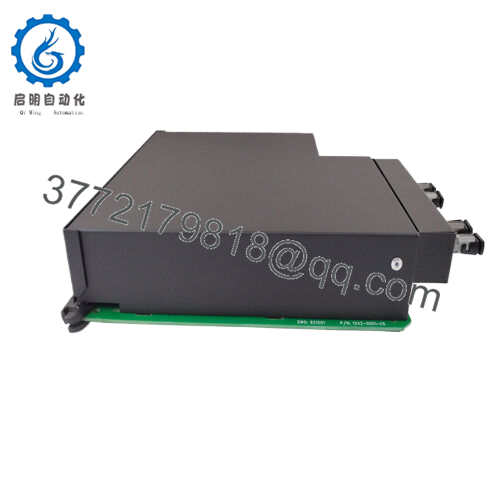

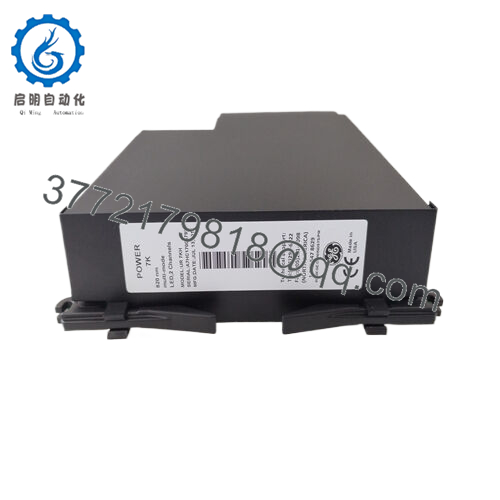

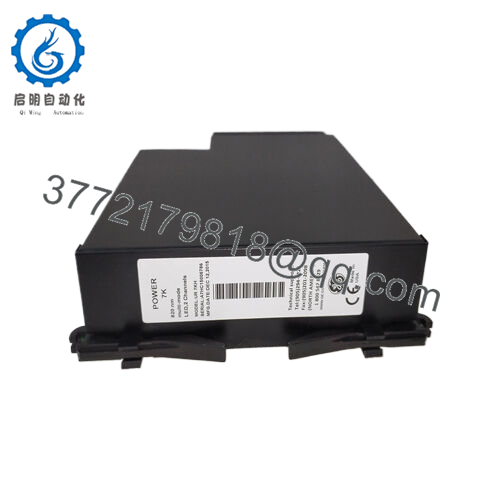

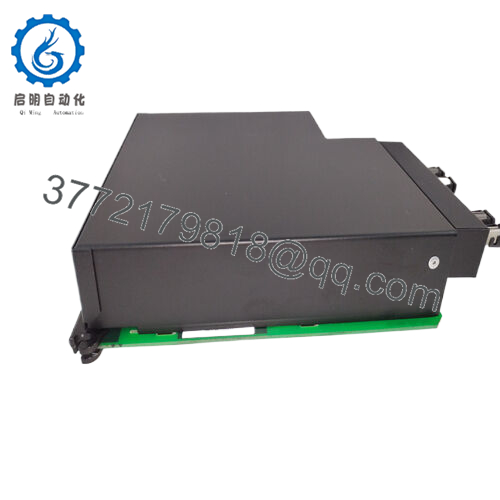

Product Model: GE UR7KH

- Product Brand: General Electric (GE)

- Product Series: Multilin UR Series

- Product Features:

- High-speed and reliable protection relay module

- Seamless integration with GE Multilin Universal Relay systems

- Robust design for demanding industrial and utility applications

- Flexible configuration for multiple protection and control functions

Applications & Industry Context

In today’s energy and industrial environments, power system reliability is more than a buzzword—it is a lifeline. Facilities in heavy industries such as steel, mining, petrochemical, and utilities operate under enormous pressure to keep downtime to a minimum. A sudden electrical fault in a substation, a transient overload in a distribution line, or a mis-coordination between feeder relays can quickly spiral into production losses and costly outages. This is where the GE UR7KH steps into the picture.

The GE UR7KH is a key module within the Multilin Universal Relay (UR) platform, which has become a standard in modern protection and control schemes. Utilities worldwide deploy it in transmission and distribution substations where selectivity and speed are critical. In refineries and chemical plants, the device ensures safe operation of motors, transformers, and feeders, often running in complex protection architectures. Large data centers rely on it to maintain continuous power availability, safeguarding sensitive IT loads.

What makes this relay module especially valuable is its adaptability. While it is rugged enough for field substations exposed to harsh climates, it also fits seamlessly into control rooms where precision and interoperability matter. The GE UR7KH has proven itself in diverse roles—from protecting industrial motors driving conveyor belts in mining operations to ensuring transformer stability in grid interconnections. By combining fast response with flexible configuration, it bridges the gap between traditional protection requirements and the evolving challenges of digital grids.

Technical Features & Benefits

At its core, the GE UR7KH is designed to deliver dependable protection while allowing engineers to configure complex schemes with minimal effort. Unlike legacy protection devices that often locked users into fixed settings, the UR platform is modular and expandable. The UR7KH module brings that philosophy into practice.

One of its standout features is high-speed fault detection. In many industrial power systems, milliseconds make the difference between a safe shutdown and equipment damage. The GE UR7KH leverages advanced algorithms to trip circuits almost instantaneously when faults are detected, reducing arc flash risks and limiting mechanical stress on connected assets.

The module also integrates seamlessly with SCADA and modern energy management systems. Its built-in communication protocols—ranging from Modbus and DNP3 to IEC 61850—allow operators to pull data directly into their control centers. This visibility gives engineers real-time insight into relay performance, breaker health, and event logs.

Reliability is another hallmark. Field engineers often note how the UR series withstands electrical noise, temperature extremes, and high-vibration environments. The GE UR7KH is tested against international standards to ensure it performs consistently under these conditions. Maintenance teams appreciate the self-diagnostic capabilities, which help identify issues before they escalate into failures.

Finally, its configurability cannot be overstated. The GE UR7KH can be tailored for protection of lines, feeders, transformers, or motors, depending on the system design. That flexibility reduces the need for multiple device types across a site, streamlining spare parts inventory and training requirements.

- UR7KH

- UR7KH

Product Role & System Fit

To understand where the GE UR7KH belongs, it helps to step back and look at the broader GE Multilin UR platform. This family of protection relays is built around a modular architecture. Instead of using separate standalone relays for each protection task, engineers can assemble modules like the UR7KH into a cohesive system.

The UR7KH plays a vital role in this architecture. Acting as both a protection and control unit, it interfaces with circuit breakers, current transformers, and voltage transformers. Its digital I/O capability allows integration into automated schemes such as breaker interlocking, load shedding, and system restoration. For operators, this means fewer manual interventions during fault conditions, leading to safer and more reliable operation.

Compatibility is another strength. The GE UR7KH can coexist with both modern IEC-based protection systems and older infrastructures still running conventional protocols. This ensures that organizations upgrading gradually can still deploy the UR7KH without massive rewiring or software overhauls.

When combined with other UR modules—such as transformer, motor, or bus protection units—the UR7KH completes a flexible protection layer. Its ability to scale from small industrial substations to large interconnected grids makes it an indispensable building block in GE’s protection ecosystem.

Technical Specifications Table

| Specification | Details |

|---|---|

| Product Model | GE UR7KH |

| Series | GE Multilin UR Series |

| Device Type | Universal Relay Module |

| Protection Functions | Line, transformer, motor, and feeder applications |

| Communication Protocols | IEC 61850, Modbus, DNP3, TCP/IP, RS485 |

| Operating Voltage Range | 24–250 VDC / 48–240 VAC |

| Input/Output Capability | Configurable digital I/O |

| Response Time | High-speed tripping in milliseconds |

| Operating Temperature | –40°C to +60°C |

| Compliance Standards | IEEE, IEC, ANSI standards |

| Mounting | Panel-mounted, modular rack design |

| Diagnostics | Self-test, event recording, waveform capture |

Installation & Maintenance Insights

For many engineers, the first encounter with the GE UR7KH is during a substation retrofit. Installation is straightforward thanks to its modular chassis design. Mounting the relay into an existing UR rack typically requires minimal wiring changes. Engineers often highlight the intuitive configuration software, which reduces setup time significantly compared to older electromechanical relays.

A key installation tip is ensuring proper grounding and shielding of communication cables. Because the relay interfaces with sensitive protection circuits, avoiding interference is critical. Using shielded twisted pair for serial communications or fiber for IEC 61850 can greatly improve reliability.

From a maintenance perspective, the GE UR7KH is designed for longevity. Routine tasks such as firmware updates, configuration backups, and relay testing can be performed without removing the unit from service for long periods. Its front-panel indicators and event records make troubleshooting much faster, often allowing technicians to pinpoint an issue within minutes.

Preventive maintenance programs benefit from the relay’s self-diagnostics. By monitoring internal health and external connections, the GE UR7KH provides early warnings before failures occur, allowing planners to schedule interventions without impacting operations.

Related Models

- GE UR6NH – Designed for advanced motor protection within the UR platform

- GE UR8KH – Extended functionality relay with additional I/O capacity

- GE UR5GH – Optimized for transformer differential protection

- GE UR9EH – High-end relay tailored for busbar protection

- GE UR4PH – Focused on feeder protection with simplified setup

- GE UR6DH – Compact relay for applications requiring limited space

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626