Description

In the realm of industrial automation, few things disrupt operations more than unexpected feeder faults—those sudden short circuits, overloads, or ground anomalies that ripple through distribution networks, triggering cascading failures in motors, transformers, and downstream loads. Picture a manufacturing facility where a subtle voltage imbalance goes undetected, escalating into equipment damage, production halts, or even safety hazards for personnel. These issues are commonplace in process control environments, from petrochemical refineries to heavy industry plants, where high reliability in power distribution is paramount. Without intelligent oversight, engineers face constant trade-offs: balancing sensitivity to catch faults early against the risk of nuisance trips that idle lines unnecessarily.

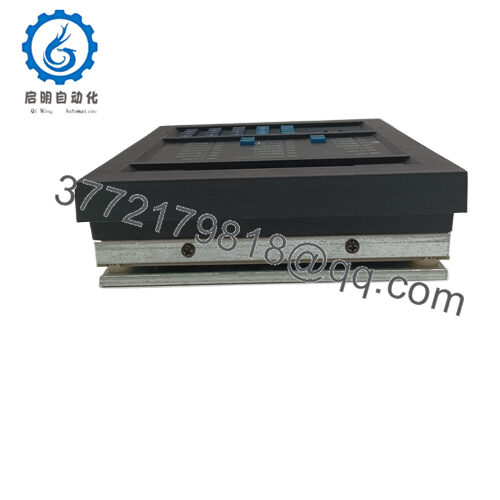

Enter the GE 1219-0003 SR760, a cornerstone of the Multilin SR series designed to deliver comprehensive feeder management and protection. This microprocessor-based relay addresses the critical need for real-time monitoring and rapid response in medium-voltage systems, ensuring system stability by integrating protection, control, and diagnostics into a single, drawout unit. It’s particularly vital in scenarios demanding modular I/O signal handling, such as expanding substations or retrofitting legacy setups, where traditional discrete relays fall short on integration speed and data granularity. For teams grappling with arc-flash risks or breaker wear in high-vibration zones, the GE 1219-0003 SR760 provides the high-fidelity metering and event recording to preempt downtime, turning reactive firefighting into proactive asset management.

- SR760 Panel 1219-0003

- SR760 Panel 1219-0003

The broader impact can’t be overstated: unchecked feeder disturbances not only inflate maintenance costs but also compromise overall process control integrity, skewing SCADA feeds and eroding predictive analytics. By embedding advanced algorithms for directional overcurrent and underfrequency detection, the GE 1219-0003 SR760 empowers precise coordination with upstream breakers, minimizing fault propagation and enhancing uptime in industrial automation backbones. It’s the kind of tool that lets you scale confidently, knowing your power layer won’t bottleneck the rest of the operation.

When deploying the GE 1219-0003 SR760 within your automation ecosystem, envision it as the vigilant sentinel at the edge of your distribution network, interfacing directly with current transformers (CTs) and potential transformers (PTs) to capture raw power signals. Housed in a rugged, drawout chassis that mounts into standard 19-inch panels, it processes these inputs through its modular I/O architecture—up to 8 contact outputs and configurable analog channels—before relaying synthesized data to central controllers via RS485 ports or Modbus RTU protocol. This positions it squarely in the field layer of your stack, bridging physical grid dynamics to supervisory systems like DCS or PLC platforms, where it supports seamless redundancy through dual power supplies and self-testing diagnostics.

In operation, the relay doesn’t just monitor; it anticipates. It scans for imbalances in real time, applying user-defined curves for time-overcurrent protection while logging waveforms for post-event forensics—all without taxing the backplane bus. Pair it with GE’s EnerVista software, and configuration becomes intuitive: tweak breaker failure logic or enable synch-check elements via drag-and-drop interfaces, ensuring compatibility with Ethernet/IP for hybrid setups. For sites with harsh EMI exposure, its conformal-coated boards and isolated channels maintain signal integrity, feeding clean telemetry upstream to avoid latency in fast-response loops. The GE 1219-0003 SR760 thrives in this role, adapting to varied architectures from radial feeders to looped configurations, and its front-panel HMI offers on-the-fly adjustments, reducing dependency on remote access during commissioning.

| Specification | Details |

|---|---|

| Model Number | 1219-0003 SR760 |

| Brand | GE Multilin |

| Type | Feeder Management Protection Relay |

| Input Voltage | 48-125 V DC / 88-300 V DC |

| Operating Temp Range | -40°C to +85°C |

| Mounting Style | 19″ Rack / Panel Drawout |

| Dimensions | 145 x 200 x 150 mm (chassis) |

| Weight | 2.5 kg |

| Interface/Bus | RS485 / Modbus RTU |

| Compliance | IEEE C37.90, CE, UL |

| Supported Protocols | Modbus RTU, DNP3 (optional) |

| Typical Power Draw | 10 W |

Opting for the GE 1219-0003 SR760 delivers a foundation of unwavering reliability, where its adaptive protection schemes ensure faults are isolated with millisecond precision, safeguarding assets without overprotecting to the point of inefficiency. In daily use, this means consistent performance across load swings, with breaker contact wear monitoring that forecasts maintenance needs, slashing unplanned outages by up to 40% in demanding process control setups. Engineered for endurance in corrosive or dusty atmospheres, it holds calibration over years of thermal cycling, providing the data depth for root-cause analysis that turns incidents into actionable insights.

What truly elevates it is the maintenance efficiency baked in: onboard oscillography captures 32 cycles of pre- and post-fault data, streamlining compliance reporting and reducing engineering overhead from hours of manual logging to quick exports. Integration eases the burden further, as its plug-compatible design with SR-series accessories minimizes rewiring during expansions, fostering a more agile automation environment. Over the lifecycle, this translates to lower total ownership costs—not just through fewer replacements, but by enabling predictive strategies that extend equipment life and optimize energy flows.

For forward-thinking operations, the GE 1219-0003 SR760 ensures long-term performance by supporting firmware upgrades via USB, keeping your system aligned with evolving standards like IEC 61850 without hardware overhauls. It’s a choice that aligns protection with productivity, letting your team focus on innovation rather than interruptions.

In utility substations, the GE 1219-0003 SR760 is routinely deployed for radial feeder protection, where continuous uptime is critical amid fluctuating renewables integration—handling overcurrent and undervoltage events to prevent blackouts in power plants, all while metering demand for billing accuracy. Its voltage-restrained logic excels in these process control environments, coordinating with reclosers to clear transient faults swiftly without manual intervention.

Water and wastewater facilities leverage it for pump station management, monitoring ground faults and load unbalances in harsh, humid conditions to maintain critical system uptime for treatment cycles. Here, the relay’s demand metering tracks energy usage across variable-speed drives, optimizing operations in fast data cycles tied to SCADA oversight.

Across mining operations, the GE 1219-0003 SR760 guards conveyor and crusher feeders against arc flashes, with sensitive earth-fault detection suited to high-resistance grounded systems—ensuring high reliability where downtime directly hits output quotas.

1219-0015 – CT input board variant for enhanced current scaling in high-amperage feeders

1219-0025 – Analog main processor upgrade for improved PT signal resolution

SR750 1219-0001 – Simplified version for basic overcurrent without advanced metering

1219-1002 – Control board add-on for expanded contact I/O in multi-feeder panels

T60 1219-0080 – Transformer-focused relay for complementary substation protection

F60 1219-0070 – Feeder alternative with integrated Ethernet for networked setups

SR469 1219-0045 – Motor management companion for downstream load safeguarding

Prior to installing the GE 1219-0003 SR760, confirm CT/PT ratios match your grid specs to avoid scaling errors—run a polarity check with a test set, and ensure the panel slot offers adequate ventilation, as heat buildup from adjacent modules can nudge performance at upper temps. Firmware should be version 4.0x or later; download the latest from GE’s portal and verify via the front RS232 before powering up. If tying into an existing Modbus network, map registers carefully to prevent address conflicts, and ground the chassis shield to your substation earth for optimal noise rejection.

Ongoing upkeep is straightforward but deliberate: monthly, glance at the faceplate LEDs for self-test alerts, and use EnerVista to pull event logs quarterly, cross-referencing against baselines to spot drift. Annually, perform secondary injection testing with a relay simulator—focus on trip curves and output timing—to validate pickup thresholds without de-energizing the line. Connector inspections every six months catch oxidation early, especially in coastal sites; a quick torque check on terminals prevents intermittent contacts. For remote diagnostics, enable DNP3 polling to your SCADA, allowing trend analysis of breaker operations without dispatching crews. This measured approach keeps the relay vigilant, with minimal intrusion on your schedule.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626