Description

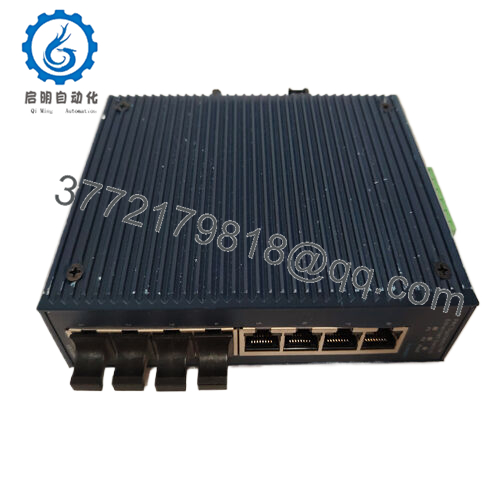

Product Model: GE SLN080 / IC086SLN080-A

Product Brand: GE (Emerson / PACSystems line)

Product Series: SLN Series Industrial Ethernet Switch

Product Features:

- 8 × 10/100Base-T(X) unmanaged Ethernet ports with fast recovery (< 10 ms)

- Wide temperature tolerance, redundant power inputs, and rugged construction

- Fault alarm relay and web-based network configuration tools

- Compact size to reduce panel footprint and ease deployment

Applications & Real-World Use Cases

Industrial facilities today demand more than just traditional cabling: they need deterministic, resilient Ethernet to carry process data, alarms, diagnostics, and control traffic. That’s where the GE SLN080 / IC086SLN080-A comes into play. As a rugged, unmanaged switch built for industrial settings, it acts as a backbone for device connectivity in constrained, harsh environments.

Consider a petrochemical plant: pumps, controllers, analyzers, motor drives, safety devices—all need to talk reliably. The SLN080 / IC086SLN080-A can be installed in control panels or junction boxes near critical equipment, linking PLCs, RTUs, HMI nodes, and I/O islands. Because of its wide temperature rating and hardening, even zones with heat, vibration, or humidity are no barrier.

In water/wastewater treatment plants, in remote pumping stations or lift stations, network stability is crucial to avoid service interruptions or spills. The fast recovery (<10 ms) characteristic of the SLN080 ensures that even if a link fails, downstream devices see minimal disruption.

Another scenario is retrofitting older plants: adding Ethernet capability without ripping out fiber or long copper runs. The compact module fits into existing racks or small enclosures. In food & beverage lines with tight control cabinets, the lower panel space used by the SLN080 frees up room for other modules or wiring.

In infrastructure like tunnels, highways, or rail, environmental stress (temperature swings, dust, vibration) is unavoidable. The IC086SLN080-A variant of SLN080 is engineered to endure those extremes, making network connectivity more reliable over time.

Technical Specifications & Attributes

Let’s dive into what makes GE SLN080 / IC086SLN080-A particularly suited for industrial networking.

| Parameter | Specification |

|---|---|

| Part Number | IC086SLN080 (model SLN080) |

| Managed / Unmanaged | Unmanaged |

| Ethernet Ports | 8 × 10/100Base-T(X) RJ45 |

| Ethernet Standards | IEEE 802.3, 802.3u, 802.3x (flow control) |

| Redundant Power Inputs | Yes — dual supply support |

| Fast Recovery | <10 ms network recovery |

| Fault Alarm Relay | Yes (relay output for fault signaling) |

| Temperature Range | Extended industrial (exact range per GE datasheet) |

| Mounting | Panel / DIN / enclosure (compact form) |

| Dimensions / Footprint | Compact — optimized for tight panel spaces (per manufacturer spec) |

| Certifications / Standards | Industrial Ethernet rugged standards (EMI, vibration survivability) |

| Web/Configuration Tool | Basic web interface for status view (though unmanaged) |

From a performance perspective, the GE SLN080 / IC086SLN080-A delivers essential industrial-grade features in an unmanaged switch topology. Its rapid fault recovery, redundant power feeds, and compact packaging distinguish it from general-purpose commercial switches.

One technical nuance: while “unmanaged” means there is no advanced VLAN, QoS, or SNMP configuration, the SLN080 still supports a minimal web-based view or local status check (LEDs and the alarm relay) to help operators verify port health or alert on a link or power failure.

Field engineers often note that the <10 ms recovery is essential in control loops: if a communication cable or switch fails, the downstream devices recover before critical timeouts—preventing cascading trips or process halts.

- SLN080 IC086SLN080-A

- SLN080 IC086SLN080-A

System Role & Integration

Within a control or automation architecture, the SLN080 / IC086SLN080-A is best viewed as a hardened link-layer node, not as a controller or logic device. It does not execute automation logic but ensures that data passes reliably between controllers, I/O, HMIs, and field devices.

In a typical cell or control zone:

- PLCs / controllers talk to I/O, sensors, actuators over Ethernet. The SLN080 sits in the middle or edge, consolidating multiple Ethernet device connections.

- For isolated field panels, the SLN080 can serve as the local switch hub, minimizing long copper/fiber runs.

- Because it offers redundant power inputs, it fits in critical zones where power fault tolerance is necessary.

- The fault alarm relay can connect to higher-level alarms or SCADA to indicate network issues proactively.

- Even though it is unmanaged, the compact footprint allows mix-and-match installations: you can have SLN080 in one segment and full managed switches elsewhere.

During retrofits, the SLN080 is often inserted into legacy control cabinets to “Ethernet-enable” older subsystems, bridging them to modern networks without dramatic infrastructure overhaul.

In a redundant network design, a pair of SLN080s might serve as “edge nodes” with dual ring or mesh connections upstream. Their fast recovery helps the network heal swiftly if one path goes down.

Installation & Maintenance Tips

From hands-on experience and field feedback, using a device like GE SLN080 / IC086SLN080-A well demands attention to wiring, environment, and maintenance.

Mounting & Ventilation

Because the module is compact, you may be tempted to cram it behind other devices. Resist that — leave some clearance (10–20 mm) around it to allow heat dissipation. Avoid placing it adjacent to hot modules or near power supplies that emit heat.

Power Wiring & Redundancy

Utilize the redundant power feed capability. Bring two separate 24 V (or your site voltage) supplies into the unit. Use properly rated and shielded cables, twisted pairs, and surge protection. Make sure the switch’s internal circuits are not starved during transient events. You’ll want fuses or circuit protection upstream.

Ethernet Cabling & Shielding

Use shielded twisted-pair (STP) cables in industrial zones. Ground shields properly (typically at one end) to avoid ground loops. Keep Ethernet runs separate from high-current power lines to reduce interference. Avoid tight bends or routing near noisy switching circuits.

Initial Commissioning

Power up in stages: energize the SLN080 first, verify LEDs, then connect devices one by one. Monitor link lights and ensure no port is in error. Use any minimal web/status interface (if supported) or check alarm relay status to detect cable faults. Log base conditions such as link latencies or drop rates.

Regular Maintenance

Industrial sites often accumulate dust, vibration stress, or temperature cycling. Periodically inspect connectors, reseat cables, ensure there’s no corrosion, and clean dust. If a port LED begins flickering or losing stability under load, swap cables first. Keep firmware or manufacturer updates in mind — even unmanaged devices sometimes benefit from bug fixes.

Spare & Replacement Planning

Given that the SLN080 / IC086SLN080-A is relatively compact and standardized, keep a spare unit with matching firmware/revision on hand. In critical installations, you can prewire the spare, label cables, and make swapout fast. The minimal configuration (unmanaged) means the replacement is typically plug-and-play.

Fault Recovery Testing

Because one of the primary advantages is fast recovery (<10 ms), it’s wise to simulate link failures and observe if downstream devices stay synchronized. Do this under controlled conditions to confirm the system’s robustness.

Related / Comparable Models

Here are several similar products or variants you might see compared or used in parallel:

- SLM080 / IC086SLM080 — managed version (with VLAN / QoS)

- SLN042 — compact 4-port variant for smaller deployments

- PACSystems managed switches — full managed equivalents in the same GE/Emerson lineup

- Industrial unmanaged switches from Hirschmann / Phoenix / Moxa — alternative brand offerings

- SLN080 variants with enhanced temperature or certification options — custom or region-specific models

These allow trade-offs among manageability, port counts, and environmental / certification levels.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626