Description

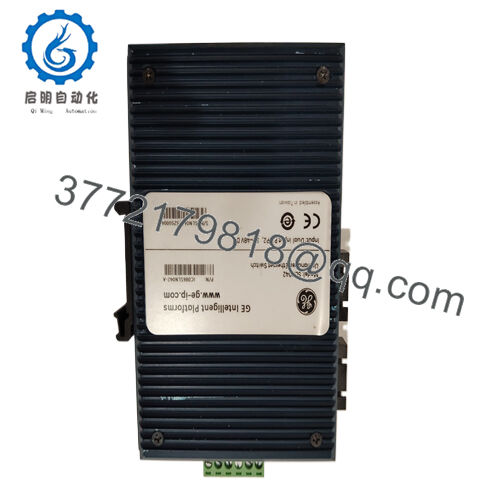

In the demanding arena of industrial automation, where reliable network connectivity amid electrical noise, temperature extremes, or power fluctuations can prevent data loss that cascades into process disruptions or safety risks, engineers often contend with switches that falter under harsh loads, lack redundant power for failover, or impose configuration burdens that delay commissioning in distributed control systems. The GE SLN042 IC086SLN042-A steps in as a compact, unmanaged industrial Ethernet switch, resolving these by delivering seamless 10/100 Mbps bridging for up to 6 ports in rugged process control environments. Picture a manufacturing floor where PLCs, HMIs, and sensors must exchange real-time I/O data over 100-meter runs—if the switch throttles under EMI from motors or drops links during surges, you’d face stalled sequences, inaccurate trending, or emergency halts that amplify downtime and costs. This switch is vital in such high-reliability scenarios, where its auto-negotiating ports and fault alarms ensure precise signal propagation, supporting modular networks that scale automation without the vulnerabilities of consumer-grade hubs.

The GE SLN042 IC086SLN042-A is especially indispensable in legacy-modern hybrid setups, like power substations or assembly lines, where its DIN-rail mount and IP30 enclosure withstand dust and vibrations while enabling quick daisy-chaining without managed overhead. By incorporating redundant power inputs and relay alarms for faults, it counters common threats like single-point failures or silent drops that plague basic switches, aligning with goals of enhanced diagnostics through LED status and SNMP compatibility. In humid, EMI-dense, or remote installations, its -40 to +70°C tolerance prevents thermal resets, fostering system uptime. Keywords like “industrial automation,” “process control,” “I/O signal,” and “high reliability” align here—the GE SLN042 IC086SLN042-A bridges connectivity gaps, minimizing engineering time for cabling tweaks and ensuring resilient data flows in environments where every packet underpins operational continuity and fault tolerance.

How the Product Works & Fits into a System

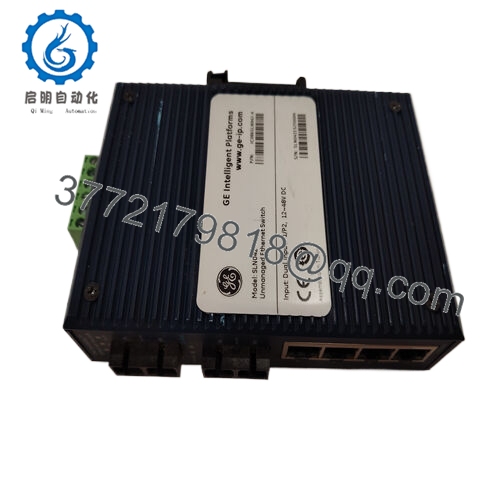

The GE SLN042 IC086SLN042-A operates as a plug-and-play Ethernet bridge in industrial networks, mounting on DIN rails within enclosures to connect devices like PLCs or VFDs via its 6x 10/100Base-T(X) RJ45 ports, automatically negotiating speeds and duplex for half/full modes without manual setup. Positioned in the network distribution layer of the automation stack, it forwards packets at wire speed with store-and-forward buffering to isolate collisions, supporting up to 100-meter Cat5e runs while the redundant 12-48 VDC inputs (with overload/reverse polarity protection) ensure failover under 10 ms. This configuration interacts with backplane systems via passthrough Ethernet, where it integrates with controllers like GE’s PACSystems or third-party PLCs for EtherNet/IP or Modbus TCP overlays, enabling daisy-chaining without repeaters in star or linear topologies.

- SLN042 IC086SLN042-A

- SLN042 IC086SLN042-A

In functionality, the switch’s unmanaged design prioritizes simplicity, with built-in surge protection (2 kV) and EMC immunity to filter noise, while a relay output signals power or link faults for external annunciation. Diagnostics include per-port LEDs for activity/speed, and optional SNMP for remote polling, making it compatible with SCADA tools like iFIX. For example, in a conveyor setup, the GE SLN042 IC086SLN042-A might link sensor drops to a central PLC, propagating I/O updates at 100 Mbps without jitter—all while its wide temp range handles 70°C enclosures. Rather than a basic hub, it actively buffers and isolates, fitting into modular Ethernet architectures where expandability counts, and reducing port counts for leaner panels in the overall process control ecosystem.

| Specification | Details |

|---|---|

| Model Number | SLN042 IC086SLN042-A |

| Brand | GE (GE Vernova) |

| Type | Unmanaged Industrial Ethernet Switch |

| Input Voltage | 12-48 VDC (redundant) |

| Operating Temp Range | -40 to +70°C |

| Mounting Style | DIN rail |

| Dimensions | 4.7″ x 3.5″ x 2.2″ (120 x 90 x 55 mm) |

| Weight | 0.4 kg |

| Interface/Bus | 6x RJ45 (10/100Base-T(X)) |

| Compliance | UL 508, CE, IP30, EMC (EN 61000) |

| Supported Protocols | Ethernet (IEEE 802.3), Auto-MDIX |

| Typical Power Draw | 7 W |

Real-World Benefits

Opting for the GE SLN042 IC086SLN042-A equips your network with a bridge built for industrial grit, where its redundant power and surge tolerance ensure long-term performance by sustaining links through 2 kV spikes, letting PLC polls flow uninterrupted at 100 Mbps even in 70°C ambients. In action, this means sensors in a mixing plant reporting levels without drops, enabling closed-loop adjustments that curb overfills and optimize batches—vital for processes where stability ties to yield or safety thresholds.

The switch’s unmanaged ease further lightens loads, as auto-negotiation trims config steps by hours in field installs, freeing teams for logic development over port mapping. Maintenance efficiency follows: relay alarms flag issues early, with DIN swaps under 5 minutes aligning with predictive scans that extend MTBF beyond 500,000 hours. For sites balancing ruggedness with simplicity, the GE SLN042 IC086SLN042-A elevates switching from a connectivity chore to a seamless enabler, fostering leaner ops where network health and process demands harmonize.

Typical Use Cases

In power substations, the GE SLN042 IC086SLN042-A chains RTU ports for breaker monitoring, its EMI immunity thriving in transformer hums and -40°C winters to deliver high reliability for process control—critical system uptime holds via fault-relayed alerts that prevent arcs in grid-tied loads.

Food processing lines deploy the GE SLN042 IC086SLN042-A for filler Ethernet drops, bridging HMIs amid steamy washdowns; its IP30 seal upholds process control precision, syncing recipes without drip-induced shorts in sanitary, high-throughput environments.

Mining ventilation fans harness the GE SLN042 IC086SLN042-A for sensor networks, daisy-chaining over dusty, 60°C shafts—its redundant inputs ensure high reliability, ventilating adits via vigilant I/O without blackout triggers in remote process control.

Compatible or Alternative Products

IC086SLN080-A – 8-port variant for denser node expansions in similar setups.

IC086SLN042-B – Managed counterpart with VLAN support for advanced segmentation.

IC200GBI001 – VersaMax bus interface for GE PLC Ethernet integrations.

IC693BSM001 – Rack power supply companion for stable feeds.

IC697LAN731 – Series 90-70 Ethernet module for legacy chassis ties.

DS200TCQCG1A – Mark V turbine board for power-specific extensions.

F650BFBF2G0HIE – Feeder relay add-on for protection overlays.

SR489-P1-HI-A20-E – Motor protection relay for complementary I/O.

Setup Notes & Maintenance Insights

Before energizing the GE SLN042 IC086SLN042-A, cross-check DIN rail alignment for secure mounting and confirm redundant 12-48 VDC feeds with isolated sources to enable failover—test polarity with a multimeter showing <50 mV ripple to avert reboots. Verify Cat5e cabling integrity up to 100 m per port using a tester for <20 ns skew, and ensure enclosure IP rating meets site needs (e.g., NEMA 4X for washdown); in EMI zones, ground shields to <1 ohm per NEC. Power up sequentially, monitoring LEDs for green links, and baseline throughput with iPerf at 95 Mbps to validate auto-MDIX.

Sustaining the GE SLN042 IC086SLN042-A emphasizes quarterly port inspections—clean RJ45 with ESD-safe wipes for dust buildup, especially in fibrous areas, and torque screws to 0.6 Nm against vibration loosening. Use a cable analyzer monthly to affirm continuity under 0.5 ohms, logging any deviations for proactive swaps; in humid locales, apply conformal coating annually to unused pins. During yearly network audits, simulate power faults to confirm relay alarms under 5 ms, but bench it: no live drops. This practical regimen, per IEEE 802.3 guidelines, keeps the switch steadfast without enclosure entries.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626