Description

In the relentless cadence of industrial power generation, where a subtle anomaly in excitation signaling can cascade into rotor imbalances or voltage instabilities, engineers confront the daunting task of upholding signal precision amid electromagnetic barrages, thermal gradients, and mechanical harmonics that plague legacy control frameworks. The GE PWB68A993125 confronts this dilemma as a specialized excitation interface printed wiring board (PWB) within GE’s legacy Speedtronic turbine control series, meticulously designed to orchestrate reliable I/O signal pathways for brushless exciter systems in industrial automation environments. Envision a synchronous generator in a peaking gas plant, where fluctuating grid demands require instantaneous field current adjustments to avert under-excitation dips; or a hydro facility enduring seismic jolts, where vibration-induced noise corrupts feedback loops, risking overfluxing and equipment strain. These are the flashpoints where process control teeters on the edge, and off-the-shelf boards succumb to the din, inflating troubleshooting cycles and eroding high-reliability benchmarks.

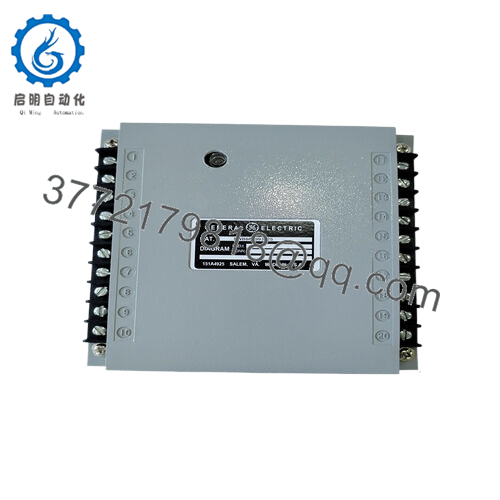

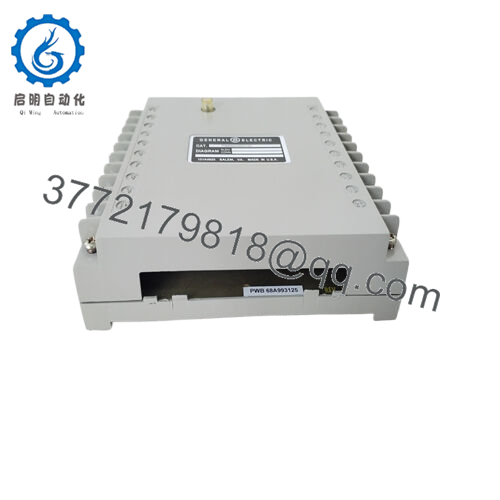

- PWB68A993125

- PWB68A993125

The GE PWB68A993125 intervenes with targeted resolve, centering on the user’s pursuit of system stability by conditioning and isolating excitation commands from the Mark IV or V controller, ensuring unerring delivery to the thyristor bridge without introducing phase lags or ground faults. In archetypal deployments—such as rehabilitating turbine governors for extended baseload runs or fortifying modular I/O architectures in renewable hybrids—it asserts itself as indispensable, displacing fragmented relay arrays with a compact assembly that embeds transient suppression for EMI resilience. Devoid of this board, operations revert to makeshift bridges—cobbled amplifiers or unshielded traces—that amplify vulnerabilities and derail modular integration in process control setups beholden to IEEE 421 standards. The GE PWB68A993125, conversely, incorporates diagnostic taps for voltage monitoring, enabling forward-looking fault isolation that synchronizes with DCS overlays for holistic oversight.

Its advisory finesse endears it to retrofit specialists: gate-drive circuitry tuned for 100 A pulses, paired with conformal coatings for humid enclosures, anticipates the engineer’s hurdles in phased upgrades. For query-driven experts scanning “excitation PWB” or “Speedtronic interface board,” it materializes as a sentinel of precision. If your automation imperatives revolve around fortifying generator health against the caprices of field flux in unforgiving rotations, the GE PWB68A993125 reimagines those exigencies as calibrated constants, moored in empirical fortitude that refines every integration calculus.

When sculpting the sinews of a turbine’s excitation loop, the discerning board doesn’t merely conduct—it anticipates the interplay of pulses and feedback, weaving fault tolerance into the very fabric of the stack without engendering bottlenecks. The GE PWB68A993125 personifies this as an interface PWB in GE’s Speedtronic lineage, dedicated to bridging the controller’s SCR firing commands to the exciter’s power stack, where it rectifies gate signals through opto-isolated drivers, filters harmonics via RC networks to preserve waveform integrity, and relays field current sense via precision shunts back to the regulator for closed-loop stabilization. It mates via multi-pin headers to the core backplane, channeling 125 V DC logic levels while segregating high-power paths to thwart arc-over, all within a deterministic 10 ms response envelope that honors TMR redundancies in Mark V evolutions.

Perched at the power-electronics frontier of the automation hierarchy, it liaises raw thyristor gates with supervisory layers like the TMR processor or HMI gateways, embracing protocols such as 4-20 mA analogs for trending or discrete flags for trip latching, with built-in crowbar diagnostics that detect overcurrent spikes and signal via relay contacts without taxing the main bus. Redundancy manifests organically: dual-trace routing mirrors critical paths for failover, while thermal fuses safeguard against latch-up in overvoltage transients, a staple for safety loops where a single glitch could desynchronize a 100 MW unit. In transitional architectures, it dovetails with brushless pilots, extending field flashing sequences from startup logic to steady-state var control, leveraging its epoxy-laminated substrate to endure 10g vibrations without trace fractures.

From an emplacement vantage, it integrates with intent—secure it to the exciter chassis via standoffs, align the fiber-optic isolates for noise-free firing, and commission baselines using the Speedtronic toolkit, its quiescent draw under 5 W suiting battery-buffered cabinets in islanded modes. The GE PWB68A993125 eclipses passive routing; it’s a dynamic mediator in your circuit’s discourse, foreseeing flux perturbations to reinforce the excitation weave against the inexorable.

| Specification | Details |

|---|---|

| Model Number | PWB68A993125 |

| Brand | GE |

| Type | Excitation Interface Printed Wiring Board (PWB) |

| Input Voltage | 115-125 V DC |

| Operating Temp Range | -20°C to +70°C |

| Mounting Style | Chassis mount with standoffs |

| Dimensions | 15 cm x 10 cm x 2.5 cm |

| Weight | 0.3 kg |

| Interface/Bus | Multi-pin headers, analog I/O |

| Compliance | IEEE 421, UL 508 |

| Supported Protocols | 4-20 mA analog, discrete logic |

| Typical Power Draw | ≤ 5 W |

Adopting the GE PWB68A993125 endows your generator regimen with a steadfastness that radiates from the exciter core outward, initiating with its isolation bulwarks that insulate against the voltaic gales of rectifier bays, where commutation notches or EMI pulses might otherwise skew firing angles and precipitate voltage hunts. In the unyielding rhythm of cyclic loading, this cements performance consistency by damping transients to <1% ripple, forestalling the efficiency erosions that nibble at pf in aggregate—envision sustaining full excitation during grid faults without the vigil of auxiliary clamps, often elevating stability margins in flux-sensitive arrays. It’s the unobtrusive steward that permits seamless var absorption, from no-load floats to full-lag burdens, infusing reliability where flux fidelity reigns supreme.

Servicing cadences sharpen appreciably, as its trace-embedded sensors—probing gate health or shunt drifts via test points—facilitate prognostic audits piped to panel meters, enabling pre-scheduled interchanges over crisis dives, which curtails outages by unmasking solder fatigue before it severs loops. The board’s lithe profile eases this, nesting beside power stacks sans cabling sprawl to diminish engineering toil in revamps, whether amplifying a legacy Mark IV for DER ties or hybridizing with static compensators. Forged for longevity, its FR-4 laminate and tinned pads defy humidity incursions, assuring protracted efficacy that outpaces ephemeral substitutes and facilitates ANSI 421 audits with innate metering hooks.

Essentially, this PWB’s potency multiplies via systemic rapport, where sense data dissects field behaviors for root hunts, streamlining adherence to NERC VAR norms. For the engineer arbitrating asset lifecycles amid fiscal squeezes, the GE PWB68A993125 concentrates high-reliability into attainable boons—slimmer downtimes, astuter diagnostics, and a bulwark that hoists excitation stewardship from obligation to eminence.

The GE PWB68A993125 embeds adroitly in gas turbine exciters of combined-cycle plants, where it modulates SCR pulses for 50 MVA rotors amid 400 Hz drone and steam cross-talk, its analog taps furnishing regulator feedback for precise V/Hz profiling that underpins critical system uptime in process control environments gunning for sub-5% regulation amid ramp rates.

In hydro generator bays, it anchors brushless pilots against water hammer vibes, its opto-gates withstanding -20°C chills while honing field flashes for black-start sequences, bolstering high-reliability loops that nix under-excitation relays during low-head surges. Fast data cycles excel herein, meshing with governors for remote tuning sans phase errors.

Broadening to industrial synchronous motors in steel mills, the board interfaces thyristor bridges in ATEX zones, parsing current senses for torque pulsation damping against arc-furnace flicker. Whether used in power plants or excitation control domains, the GE PWB68A993125 girds rigorous-condition bastions, amalgamating signal acuity with power poise for resilient, potency-centric endeavors.

PWB68A993124 – Predecessor variant with legacy 115 V gating, apt for Mark IV retrofits in voltage-constrained auxiliaries.

PWB127A1145 – Augmented power board companion for higher-current exciters in aero-derivative setups.

DS3800NDAC1A – AC input module that feeds the PWB68A993125 for enhanced harmonic rejection in grid-tied gens.

DS3800HMPH1A – Processor host for Speedtronic integration, enabling TMR oversight of the interface PWB.

PWB68A993126 – Fiber-isolated upgrade for EMI-heavy enclosures, suiting offshore hydro installs.

DS200TCQAG1A – Terminal companion for expanded I/O tying into excitation signaling chains.

PWB127A1146 – Output driver add-on for crowbar actuation, bolstering fault response alongside the core board.

Prior to affixing the GE PWB68A993125 to its chassis, a discerning pre-alignment can parry those nascent fitment foibles that elongate power-up phases. Collate header pinouts with the exciter schematic per GE’s legacy matrix—disjunctures spawn firing asymmetries, so mock a continuity loop on a donor frame with a variac sweep. Chassis congruity merits heed; gauge for 2.5 cm standoff clearance to avert shorting against heatsinks, and in thermal pockets, affirm 15 mm airflow vents to cap junction rises below 85°C. Assay the 125 V bus for <50 mV noise under simulated pulse loads—sags incite erratic commutation—and corroborate shield bonds on sense leads to stifle common-mode ingress from inception.

In tenure, tending veers toward perceptive, epochal inspections that capitalize on its passivity. Bimonthly test-point probes—voltmeter on gate biases or shunt drops—expose trace delams or fuse pops early, routinely via panel readouts over bench teardowns. Quartersawn, scrutinize solder joints for microcracks (magnify at 10x) and torque header screws to 0.4 Nm, particularly in oscillatory mounts where thermal cycling migrates alloys; append a hi-pot across isolates to nab dielectric erosion. Annually, enact a full pulse regimen through the toolkit, benchmarking waveform fidelity against OEM envelopes—coordinate with any archival bulletins from the archive for obsolescence bridges. In saline or particulate venues, a biennial IPA swab over pads expunges flux relics sans abrasion perils. These aren’t sweeping edicts; they’re attuned to your exciter’s throb, upholding keenness while reallocating zeal to refinements over rectifications.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626