Description

In the intricate web of modern electrical distribution, where harmonics from variable frequency drives or nonlinear loads can silently erode equipment lifespan and inflate energy bills, engineers face the uphill battle of pinpointing power quality anomalies before they trigger failures or compliance violations. The GE PQMII-T20 steps in as a sophisticated digital power quality meter from GE Vernova’s Multilin series, engineered to deliver granular visibility into three-phase systems, capturing transients, sags, and swells that elude basic metering in industrial automation landscapes. Imagine a data center humming under UPS-backed loads, where a voltage dip from upstream switching cascades into server glitches and lost transactions; or a manufacturing floor riddled with welders and inverters, where harmonic distortion spikes THD beyond IEEE 519 thresholds, compromising motor efficiency and inviting fines. These are the crucibles where process control demands more than snapshots— it craves continuous, forensic tracking to safeguard high-reliability operations without drowning in data overload.

The GE PQMII-T20 meets this need by focusing on the user’s imperative for system stability, metering essentials like current, voltage, real/reactive power, energy consumption, power factor, and frequency while dissecting disturbances via waveform capture and harmonic analysis up to the 63rd order. In routine flashpoints—such as retrofitting substations for renewable tie-ins or embedding into modular I/O frameworks for facility-wide monitoring—it emerges as crucial, supplanting rudimentary panel meters with programmable setpoints and four assignable output relays that automate responses like load shedding or alarm triggers. Without it, teams resort to siloed tools—handheld analyzers or fragmented loggers—that fragment insights and escalate diagnostic times in process control environments tethered to NERC or IEC standards. The GE PQMII-T20, however, embeds voltage disturbance recording (VDR) to log dips and interruptions with timestamped precision, fostering proactive interventions that align quality metrics with operational goals.

Its consultative insight resonates with deployment pros navigating hybrid grids: configurable analog outputs retransmit key parameters for SCADA integration, while RS485 Modbus ensures plug-in compatibility sans protocol gymnastics. For search-oriented specialists querying “power quality meter harmonics” or “GE Multilin PQMII specs,” it stands as a beacon of actionable intelligence. If your automation challenges orbit around taming electrical noise for sustained uptime in dynamic loads, the GE PQMII-T20 recasts those enigmas as illuminated pathways, grounded in empirical depth that hones every monitoring mandate.

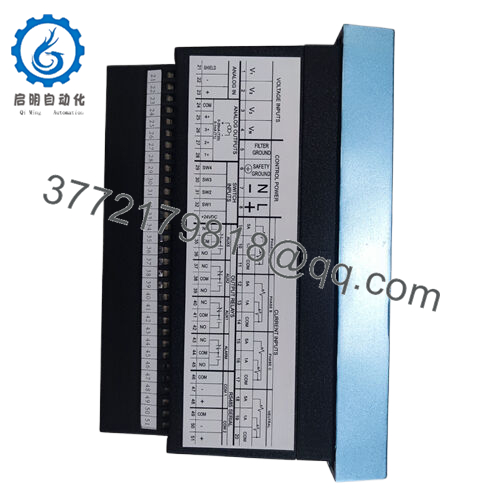

When orchestrating a facility’s electrical nervous system, the right meter doesn’t just observe—it interprets the flux of waveforms to inform control decisions, bridging raw AC signals to networked oversight without injecting latency or blind spots. The GE PQMII-T20 embodies this as a compact PQM II unit in GE Vernova’s metering portfolio, sampling three-phase inputs through voltage/current transformers to compute phasor-based metrics, then flagging excursions like 95% sags or 5% swells via threshold logic that actuates relays for sequenced alerts. It funnels this intelligence through an RS485 port using Modbus RTU for polling by PLCs or RTUs, while four isolated 0-20 mA analog outputs mirror variables like demand kW or THD(V) to analog recorders, enabling seamless handoffs in backplane-less setups where space constraints rule.

- PQMII-T20

Positioned at the distribution tier of the automation stack, it interfaces field CTs/VTs (up to 600 V phase-to-phase) with upper-layer historians or HMIs, supporting DNP 3.0 for utility-grade telemetry and optional Ethernet for GOOSE messaging in IEC 61850 fabrics, all while its DSP core sustains 256 samples-per-cycle resolution for transient fidelity. Diagnostics unfold accessibly: a front LCD scrolls real-time values or event logs, with configurable histograms tallying disturbance frequency over 24-hour windows, and self-tests verify input scaling without halting scans. In distributed architectures, it scales via daisy-chained RS485 segments, buffering harmonic spectra to preempt resonance in capacitor banks, a nod to legacy integrations where it emulates analog transducers minus the drift.

From a rollout perspective, it deploys with pragmatic simplicity—panel-mount the drawout case into a 19-inch rack, secure compression terminals for 5 A CTs, and baseline harmonics against load profiles using EnerVista Pro, its low 20-60 V DC draw fitting solar-auxiliary cabinets in off-grid outposts. The GE PQMII-T20 outstrips passive logging; it’s an astute sentinel in your grid’s lexicon, prognosticating quality lapses to reinforce the metering matrix against the volatile.

| Specification | Details |

|---|---|

| Model Number | PQMII-T20 |

| Brand | GE Vernova |

| Type | Digital Power Quality Meter |

| Input Voltage | 20-60 V DC / 20-48 V AC |

| Operating Temp Range | -40°C to +85°C |

| Mounting Style | Panel mount, drawout case |

| Dimensions | 144 mm H x 192 mm W x 103 mm D |

| Weight | 2.7 kg |

| Interface/Bus | RS485 Modbus RTU |

| Compliance | IEEE C37.90, CE, UL |

| Supported Protocols | Modbus RTU, DNP 3.0 |

| Typical Power Draw | ≤ 15 W |

Selecting the GE PQMII-T20 imbues your electrical oversight with a diagnostic acuity that reverberates through operations, commencing with its waveform scrutiny that unmasks transients in microseconds, averting the insidious creep of insulation stress that could fell transformers prematurely and reclaim megawatt-hours in preempted derates. In the perpetual flux of industrial loads, this secures performance consistency by auto-bucketing harmonics into IEC-compliant reports, sidestepping the output variances that plague uncalibrated gear—picture sustaining 99% availability during peak draws without the fog of unlogged swells, often honing energy audits to trim penalties by 10-15% in tariffed regimes. It’s the discreet oracle that empowers demand-response tweaks, metering cost-of-power in real time to optimize capacitor switching sans manual patrols.

Upkeep trajectories refine notably, as its relay-driven outputs latch setpoint breaches for remote interrogation, channeling logs to SCADA for trend forensics that forecast breaker wear before it strands circuits, thereby condensing site audits and engineering drudgery in sprawling plants. The meter’s lithe drawout eases this, permitting element pulls under voltage to curtail outages in live upgrades, while its 4-20 mA scalability mates fluidly with DCS spines, diminishing overhead for sites grafting EVs onto legacy feeders. Built for grit, the wide temp span and conformal internals defy enclosure heat or coastal brine, promising enduring vigor that eclipses transient rentals and streamlines EN 50160 validations with innate disturbance tallies.

At its nucleus, the GE PQMII-T20 magnifies reliability as a systemic catalyst, where captured spectra inform filter designs or load balancers, easing fidelity to PQ standards. For the engineer weighing expansions against volatility, it concentrates high-reliability into tangible boons—sharper foresights, leaner interventions, and a rampart that lifts quality guardianship from chore to cornerstone.

The GE PQMII-T20 deploys nimbly in commercial high-rises, where it patrols elevator banks and HVAC inverters for sag-induced glitches, its VDR logging 512-cycle captures amid fluorescent flicker to enforce critical system uptime in process control environments bent on Tier III resilience—vital for quelling CBEMA excursions during brownout drills.

In wastewater treatment plants, it embeds in MCCs to profile pump harmonics under VFD surges, its DNP feeds syncing with SCADA for predictive var compensation in humid vaults that corrode lesser housings. High-reliability THD tracking here nips motor overheating, upholding fast data cycles for remote overrides.

Spanning to solar farm inverters in utility yards, the meter dissects string imbalances via phasor diagrams, its Modbus polls dissecting flicker from cloud transients in sun-baked exposures. Whether used in power plants or power quality monitoring domains, the GE PQMII-T20 steels exacting-condition sentries, fusing metric depth with comms dexterity for resilient, thrift-oriented pursuits.

PQMII-T20-C – Current-only variant with enhanced CT scaling for feeder-level granularity in distribution panels.

PQMII-T21 – Upgraded model with Ethernet option for GOOSE integration in substation automation.

PQMII-T10 – Basic metering sibling sans harmonics, suited for cost-lean revenue tracking in small loads.

SR735-P5 – Feeder protection companion for overcurrent tie-ins alongside PQ analysis.

PQMII-T20-R – RTD-augmented version with temp inputs for thermal-PQ correlation in motor controls.

MIFII4E – Legacy feeder meter alternative for Modbus-only retrofits in legacy SCADA.

PQMII-T30 – Advanced transient recorder add-on for waveform depth in arc-flash studies.

Before energizing the GE PQMII-T20 in its panel, a succinct alignment check can deflect those startup subtleties that protract tuning. Align Modbus slave IDs with the master PLC per GE’s comms primer—clashes yield query stalls, so stage a loopback test on a lab feed with dummy VTs. Case accommodation figures; allot 10 mm bezel clearance for LCD views and door swings, and in dusty vaults, verify IP54 seals to bar grit from CT terminals. Probe the T20 supply for hold-up—simulate a 50 ms dropout to confirm it sustains above 18 V, as glitches reset the DSP mid-scan—and affirm VT polarity with a phase rotation meter to nix reversal artifacts from outset.

In play, nurturing skews to perspicacious, cyclical peeks that harness its vigilance. Fortnightly LCD scrolls—watt-hour tallies or THD trends—betray input drifts or relay sticks early, harvestable via DNP queries over physical pokes. Biannually, audit compression lugs for torque (0.7 Nm) and megger outputs amid humid cycles where creepage lurks; tack on a scaling verify with injected sine waves to hone accuracy curves. Yearly, unleash a full event replay in EnerVista, benchmarking sag thresholds against site logs—mesh with firmware infusions from the hub for protocol drifts. In variable-load zones, a quarterly harmonic sweep via test kit affirms filter efficacy sans resonance hunts. These aren’t draconian; they’re synced to your grid’s undulation, conserving perspicuity while funneling vigor to adaptations over alleviations.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626