Description

In the demanding arena of turbine and generator control, where communication delays or network failures can cascade into unsafe shutdowns or inefficient load sharing—picture a gas turbine in a peaking plant where fragmented Ethernet packets disrupt governor sequencing, leading to frequency deviations and fuel waste, or a steam cycle in a combined-heat-power setup where redundant control links falter under EMI, exposing processes to instability and regulatory non-compliance—these risks erode system resilience and amplify recovery efforts in process control environments. Engineers often navigate legacy DCS architectures where standard switches introduce latency or single points of failure, resulting in signal distortion, scalability hurdles, or diagnostic gaps that prolong outages and inflate engineering costs in high-reliability industrial automation. The GE IS420UCSBH1A emerges as a robust UCSB controller module from GE Vernova’s (formerly GE) Mark VIe series, serving as a standalone processing unit with integrated Ethernet connectivity to execute application logic, ensuring deterministic I/O signal distribution and seamless redundancy in turbine management systems.

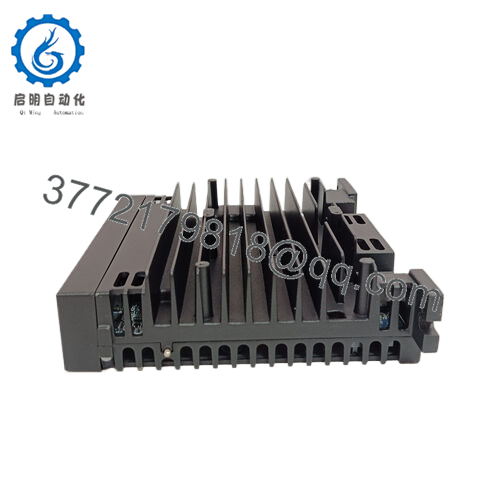

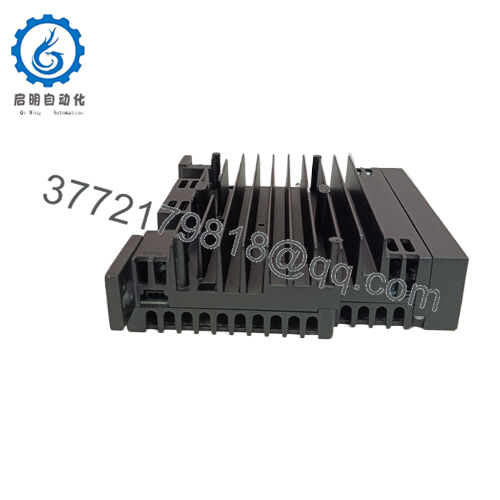

- GE IS420UCSBH1A

This module proves essential in scenarios like upgrading Mark VI to VIe for enhanced cybersecurity, where its compact, fanless design slots into existing racks without thermal overhauls, or in aero-derivative turbines demanding triple modular redundant (TMR) voting for fault-tolerant operations. In a solar thermal plant’s heliostat tracking, for instance, it processes position commands amid solar flux variability, delivering high-reliability Ethernet streams that synchronize mirrors without desync-induced hotspots. For offshore gas platforms with humid, vibration-laced cabinets, the GE IS420UCSBH1A leverages its wide DC input range for uninterrupted logic execution, upholding process stability without compromising on hot-swappable redundancy. It’s particularly critical for modular expansions in multi-shaft configurations, where its compatibility with EX2100e and LS2100e bridges legacy exciters to modern SCADA, focusing on your goals of minimized single points of failure in EMI-saturated or thermal-challenged zones.

At its core, it champions your deployment priorities: with a 600 MHz Intel EP80579 processor for real-time task handling, it supports dual Ethernet ports for ring topologies that evade link breaks. In protocol-dense plants or bandwidth-limited grids, its embedded toolbox software quells multicast overloads, while self-tests flag CPU drifts early. For teams modernizing Speedtronic fleets, the GE IS420UCSBH1A simplifies persistence, reusing Mark VIe footprints to defer full-system swaps, redirecting emphasis from network firefighting to optimized sequencing in industrial automation where control fluency safeguards every shaft rotation.

Integrating the GE IS420UCSBH1A into your turbine architecture casts it as the autonomous logic engine within GE’s Mark VIe ecosystem, where it runs application code on its isolated processor while interfacing I/O networks via Ethernet for data exchange with field modules like IS420ESWB. This controller mounts in VME-compatible racks or standalone panels, positioning at the TMR voting layer—directly executing control algorithms but relaying status upward through Profibus or HMI links for supervisory oversight. In a stratified stack, it collaborates with UCSC siblings for redundant voting or downstream PAII packs for analog termination, distributing computations across three channels to circumvent single-channel faults.

In action, it processes up to 1 ms cycle times for PID loops, syncing dual 10/100Base-TX ports for RNRP redundancy with sub-50 ms failover, while onboard flash stores firmware for quick recoveries. Diagnostics integrate via LEDs and serial ports, surfacing task utilization or link health in ToolboxST software for remote analysis—pivotal in process control where off-site dashboards outpace on-site interventions. Without native I/O termination, it thrives in TMR configs, where heartbeat polling ensures bumpless handover, and its battery-less design fortifies against power glitches in remote sites.

This embeddability extends to hybrid setups: snap it into IP54 enclosures with shielded cabling, parameterize logic via Ethernet uploads, and validate cycles with built-in simulators to confirm against jitter. For rack veterans, the GE IS420UCSBH1A demystifies TMR, turning standalone units into resilient voters that scale with turbine complexity, enhancing industrial automation from isolated controllers to synchronized sentinels.

| Specification | Details |

|---|---|

| Model Number | IS420UCSBH1A |

| Brand | GE Vernova |

| Type | UCSB Controller Module (Mark VIe Series) |

| Input Voltage | 18-30 VDC |

| Operating Temp Range | -30°C to 70°C |

| Mounting Style | VME Rack / Panel |

| Dimensions | 265 x 160 x 50 mm |

| Weight | 1.2 kg |

| Interface/Bus | Ethernet (2x 10/100Base-TX), RS-485 |

| Compliance | CE, UL, ATEX Zone 2, RoHS |

| Supported Protocols | Profibus DP, Modbus RTU |

| Typical Power Draw | 25 W |

Opting for the GE IS420UCSBH1A delivers unyielding logic execution that weathers operational storms, its 600 MHz processor sustaining 1 ms determinism for sequences where lags compound into turbine rubs or overspeeds, while TMR architecture preserves 99.999% availability amid channel faults that sideline lesser units. This steadfastness curbs process deviations by isolating computations per voter, steadying governors in variable-load zones like peaking plants where desyncs mean emissions spikes, all while its fanless chassis shrugs 70°C ambients without airflow dependencies.

The integration edge compounds through Mark VIe synergy, where it reuses Ethernet backbones to repurpose cabling for expansions like HRSG controls, slashing deployment from days to diagnostics and easing opex in multi-site fleets. Maintenance evolves via embedded health logs that surface CPU loads preemptively, condensing fault hunts from rack teardowns to remote pulls—fostering proactive tuning over reactive scrambles. Engineered for endurance in steamy or dusty bays, it holds cycle fidelity across swings, deferring verifications and aligning with MTTR goals in regulated ops.

Over time, these traits optimize total ecosystem efficiency, drawing just 25 W to lighten thermal burdens on shared rails and extending allied module lifespans. In high-reliability scenarios, the GE IS420UCSBH1A minimizes ownership risks, from RNRP rings that sustain links during fiber snaps to supervision that chronicles states for compliance audits, forging a control fabric that adapts to transients in turbine management.

In gas-fired peaking stations, the GE IS420UCSBH1A executes fuel valve logic, voting TMR signals amid combustion roar to secure critical system uptime in process control environments where sequence fidelity averts lean-burn stalls. Its high-reliability Ethernet processes I/O signals from governors, ensuring load-ramp precision.

Nuclear steam bypass systems deploy it for redundant sequencing under containment chills, overseeing multi-channel interlocks for nonstop cooldowns—delivering fault-tolerant paths that uphold signal purity and continuous uptime in safety bays. In aero-derivative drives for oil export terminals, it synchronizes shaft speeds against torque flux in humid vaults, supporting modular expander integrations. These applications underscore the GE IS420UCSBH1A as a TMR titan in rugged, sequence-strict industrial automation, where controller cunning meets resilience.

IS420UCSBH2A – Enhanced variant with quad voting for ultra-high-integrity loops in nuclear applications.

IS420UCSCB1A – Base UCSC model for non-TMR setups with similar Ethernet but reduced redundancy.

IS420ESWBH3A – Ethernet switch companion for expanded network ports in Mark VIe racks.

IS420SICIH2A – Safety interface card add-on for SIL-rated interlocks.

IS420PAIIH2A – Analog input module for field termination in TMR chains.

Mark VIe TMR Kit – Redundancy toolset for triple-voter configurations.

IS420UCSBS1A – Simplified standalone version for basic turbine logic.

EX2100e UCS Module – Exciter-compatible controller for generator tie-ins.

Before rack-mounting the GE IS420UCSBH1A, audit backplane compatibility—Mark VIe slots require precise pin alignment to avoid ghosting, and verify firmware parity with ToolboxST if blending revisions. Probe DC feeds for <5% ripple under peak loads, as noise corrupts Ethernet; isolate with ferrites if nearby converters hum. Allocate vent space in cabinets to stay below 70°C, especially when stacking with heat-generating I/O.

Once live, maintenance centers on low-impact routines that sustain performance without derailing shifts. Bi-weekly, scan front LEDs for heartbeat and fault pulses—uniform greens signal nominal, but ambers warrant a log pull via Ethernet to trace cycle overruns. Semiannually, reseat Ethernet jacks for oxidation and run a self-test sequence to validate TMR sync against baselines, confirming failover under 50 ms. In humid or dusty spots, a quarterly soft wipe of ports suffices, paired with torque checks on DIN clips to counter vibration creep. These steps, per GE’s Mark VIe manual, emphasize prevention over cure, positioning the GE IS420UCSBH1A as a low-touch asset in your turbine control lineup.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626