Description

The GE IS420ESWBH3A is extensively deployed in industrial automation environments where reliable high-speed Ethernet communication is essential for real-time control and monitoring. It is particularly applicable in turbine control systems such as GE’s Mark VIe platform, which supports power plants, wind farms, and other heavy industries requiring precise, low-latency data exchange. The switch acts as a communication backbone that connects multiple control system components, ensuring seamless data transfer between controllers, sensors, and actuators.

Industries using this switch gain from its robust performance in harsh and variable conditions—ranging from cold outdoor installations to heat-intensive indoor control rooms. Its emphasis on copper Ethernet connectivity suits facilities with existing network infrastructures preferring cost-effective, durable cabling solutions over fiber optics. By providing stable and deterministic network paths, the GE IS420ESWBH3A enhances system responsiveness and uptime, addressing challenges such as signal interference and network congestion common in industrial settings. This switch is thus widely used in industrial automation, turbine control, and process control systems requiring dependable network communication.

Product Introduction and Positioning

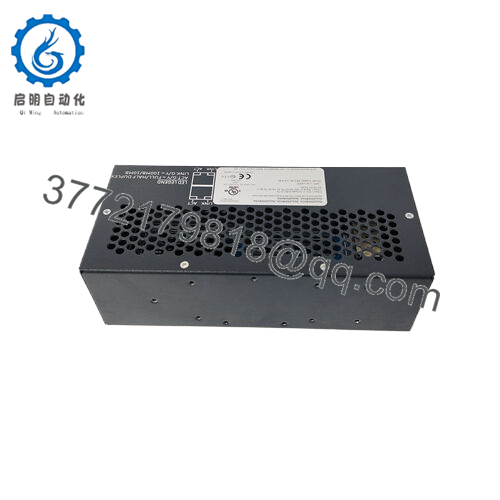

The GE IS420ESWBH3A is a dedicated industrial Ethernet IONet switch manufactured by General Electric as part of the Mark VIe series. Functioning as a network communication hub, this device supports up to 16 copper 100Base-TX Ethernet ports, enabling connectivity within advanced turbine control and automation systems. It consolidates network traffic among controllers and field devices, contributing to the overall distributed control system’s stability and performance.

Positioned in the Mark VIe control system stack, GE IS420ESWBH3A plays a vital role in data routing and signal management. Its compatibility with the common 24/28 VDC industrial power supply and support for standard Category 5e copper cables make it an integrable and flexible option for system designers. The switch’s role simplifies complex network architectures by providing reliable and manageable connectivity, which engineers and integrators rely on to maintain high availability and facilitate scalable network expansions without compromising control precision.

Key Technical Features and Functional Benefits

The GE IS420ESWBH3A switch excels with its robust 16-port copper Ethernet design, optimized for industrial environments requiring fast, low-latency network communication. Without fiber optic ports, it emphasizes simplified deployment where fiber infrastructure is unavailable or unnecessary, easing installation complexity and reducing maintenance overhead. Its support for 10/100 Mbps speeds with full and half-duplex auto-negotiation provides versatile connectivity options tailored to varying network demands.

Built to withstand extreme temperature conditions, the switch operates over a broad range from -40 to 70°C, ensuring reliable performance in both outdoor and challenging indoor environments. Its convection cooling system eliminates moving parts, thereby lowering failure risks and maintenance requirements crucial for 24/7 industrial operations. The compact yet rugged design fits conveniently in control cabinets with DIN-rail or panel mounting options, allowing seamless integration into existing infrastructure.

Compatibility with Cat 5e UTP cables outfitted with RJ45 connectors standardizes connectivity and supports industry-preferred wiring schemes. The GE IS420ESWBH3A is G3 compliant and designed with vented modular construction, increasing serviceability while preserving signal integrity. Altogether, these features make the device ideal for engineers and maintenance teams focused on system reliability and efficiency in fast-paced industrial automation settings.

- IS420ESWBH3A

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE IS420ESWBH3A |

| Brand | General Electric (GE) |

| Product Type | Industrial Ethernet IONet Switch |

| Power Supply | 24/28 VDC |

| Operating Temperature | -40 to 70°C |

| Mounting | DIN-Rail or Panel Mounting |

| Dimensions | 18.8 cm (H) x 8.6 cm (W) x 5.6 cm (D) |

| Weight | Approximately 2 lbs |

| Interfaces | 16 x 100Base-TX Copper RJ45 Ethernet |

| Fiber Ports | None |

| Cooling | Convection Cooled |

| Certifications | G3 Compliant |

| Compatible Cables | Cat 5e UTP Cable with RJ45 Connectors |

Related Modules or Compatible Units

IS420ESWBH3AE – Variant with similar copper port configuration including fiber optic ports for hybrid connectivity.

IS210AEAAH2B – Input/output PCB used in the Mark VIe series, complementing network communication modules.

IS215AEPSG1A – Power supply board supporting stable power delivery within the Mark VIe ecosystem.

IS212AESWBH1B – Ethernet switch with fewer ports, suitable for smaller network topologies.

IS215AEPCH1A – Pitch control board commonly paired in turbine control systems using Mark VIe components.

Installation Notes and Maintenance Best Practices

When installing the GE IS420ESWBH3A, verify the physical space in the control cabinet to ensure proper airflow and easy access for wiring. The device supports DIN-rail or panel mounting, so select mounting hardware appropriately, and ensure power supply and grounding align with industrial electrical standards to prevent signal interference or damage from electrical noise. Confirm network cable quality and routing to maintain optimal signal integrity and reduce electromagnetic interference risks.

Maintenance should include periodic visual inspections for dust accumulation or physical damage, especially around the RJ45 ports and ventilation areas to prevent overheating. Network diagnostics tools are recommended to monitor port activity and detect signal issues early. Firmware updates, if applicable, should be applied by certified personnel to enhance security and add new features. Keeping the unit clean and maintaining a controlled environment will maximize operational lifespan and network reliability.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626