Description

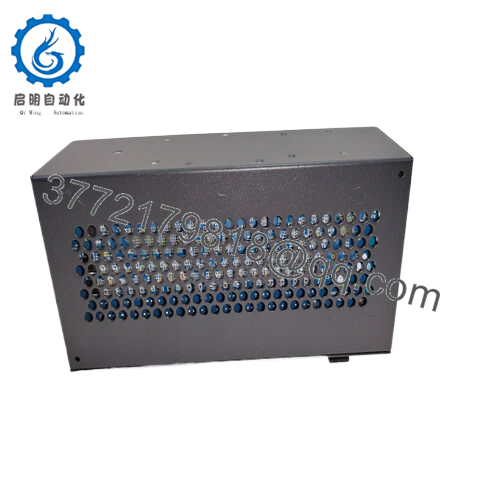

In the pulse-racing arena of gas turbine management, where split-second data flows dictate everything from fuel efficiency to grid synchronization, engineers wrestle with the specter of network bottlenecks that can unravel even the most fortified control systems. Enter the GE IS420ESWBH2A, a rugged Ethernet IONet switch crafted to conquer connectivity chaos in high-stakes industrial automation. At its core, it solves the pressing need for deterministic, low-latency communication in environments plagued by electromagnetic interference, thermal flux, and relentless vibration—scenarios where a dropped packet might cascade into turbine trips or suboptimal loads, spiking costs and compromising safety.

Think of a peaking power station juggling variable renewables, where controllers and I/O modules demand seamless IONet threading to maintain process control precision; without reliable switching, signal degradation leads to erratic responses, inflating maintenance calls and regulatory scrutiny. Or consider offshore platforms, where salt-laced air and seismic jolts amplify the urgency for high-reliability networking that buffers multicast streams without overwhelming buffers. The GE IS420ESWBH2A steps up by delivering unmanaged, plug-and-play Ethernet bridging that prioritizes system stability, filtering noise while enabling auto-negotiation for copper and fiber links alike. In these pressure-cooker setups, it becomes non-negotiable, supplanting fragile consumer-grade switches with industrial-grade fortitude that aligns with SIL-rated architectures.

- IS420ESWBH2A

- IS420ESWBH2A

This switch’s consultative appeal lies in its foresight for modular integration, allowing teams to scale IONet topologies without ripping out cabling or retooling protocols. By embedding features like redundant power inputs and status LEDs, it shifts focus from firefighting latency issues to optimizing throughput—vital for search-savvy pros hunting terms like “turbine Ethernet switch” or “high-reliability IONet.” Ultimately, if your automation blueprint hinges on unbreakable data highways amid operational turbulence, the GE IS420ESWBH2A recasts those risks as reliable thoroughfares, informed by battle-tested performance that underpins smarter decision-making in turbine-centric ecosystems.

Navigating the intricacies of a turbine control network, you need a switch that doesn’t just connect—it anticipates the ebb and flow of data across your stack, ensuring every node stays in lockstep. The GE IS420ESWBH2A excels here as an unmanaged IONet hub within GE’s Mark VIe framework, channeling traffic from distributed I/O packs to central controllers via its 16 copper ports and dual fiber uplinks. It ingests Ethernet frames from field devices—like vibration monitors or valve actuators—applies store-and-forward logic to sequence them without collisions, then dispatches them onward with minimal jitter, all while honoring 802.3x flow control to throttle floods in congested loops.

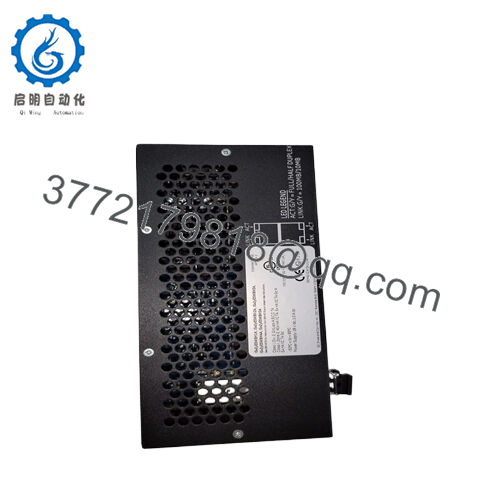

In the broader automation hierarchy, it occupies the connectivity layer, linking low-tier sensors through backplane IONet to upper-echelon HMIs and SCADA overlays, fostering a unified fabric for real-time diagnostics and redundancy handoffs. Dual power feeds, diode-OR’d for failover, keep it humming if one source falters, while multi-mode fiber ports extend reach up to 2 km for spanning turbine enclosures without signal loss. Protocols like 10/100Base-TX auto-sense on RJ-45s mean it meshes effortlessly with legacy Profibus gateways or modern Ethernet/IP endpoints, reducing integration friction in hybrid DCS migrations.

Practically speaking, commissioning feels intuitive: mount it on a DIN rail, wire the Phoenix connectors for power, and watch LEDs illuminate link status per port—no console commands or VLAN configs required, unlike managed alternatives that demand IT-level tweaks. It buffers up to 256 KB across 4K MAC addresses, queuing multicast diagnostics from safety modules without dropping critical alerts, which proves invaluable in safety-integrated Mark VIeS setups. For the deploying engineer, the GE IS420ESWBH2A embodies adaptive resilience, evolving with your network’s demands—from baseline turbine syncing to expanded renewable tie-ins—while its EMI-shielded enclosure guards against the industrial grit that fells lesser gear.

| Specification | Details |

|---|---|

| Model Number | IS420ESWBH2A |

| Brand | GE |

| Type | Unmanaged IONet Ethernet Switch |

| Input Voltage | 24/28 V DC, 1 A max |

| Operating Temp Range | -40°C to 70°C |

| Mounting Style | DIN-rail (clip required) |

| Dimensions | 18.8 x 8.6 x 5.6 cm |

| Weight | 0.9 kg |

| Interface/Bus | 16x 10/100Base-TX RJ-45, 2x 100Base-FX LC fiber |

| Compliance | ATEX Zone 2, Class 1 Div 2, G3 |

| Supported Protocols | IEEE 802.3, 802.3u, 802.3x |

| Typical Power Draw | ≤ 15 W |

Selecting the GE IS420ESWBH2A equips your turbine ecosystem with a networking backbone that quietly amplifies uptime, starting with its engineered tolerance for extremes that keeps data flowing when lesser switches stutter. In the grind of 24/7 operations, where brownouts or surges could isolate modules and halt sequencing, its soft-start circuit caps inrush to under 200% of nominal draw, ensuring stable handoffs that preserve process control loops and avert those margin-eroding scrams. This reliability cascades into performance consistency, as auto-MDIX on ports sidesteps cabling headaches, letting teams deploy faster and iterate on controls without network-induced variances.

Maintenance efficiency gets a boost too, with per-port LEDs that spotlight duplex mismatches or activity lulls at a glance, empowering ops staff to triage remotely via integrated diagnostics rather than chasing ghosts across the floor. Integration ease further lightens the load—its form factor slips into crowded cabinets alongside I/O racks, minimizing footprint while extending fiber runs for cleaner topologies that reduce engineering overhead in retrofits. Over cycles, this fosters long-term performance by buffering streams judiciously, preventing buffer overflows that plague broadcast-heavy environments and extending the viability of your Mark VIe investment.

What truly sets it apart is how it transforms connectivity from a vulnerability to a virtue, where redundant feeds and flow control ensure fault-tolerant exchanges that align with evolving safety mandates. For engineers balancing capex against opex, the GE IS420ESWBH2A delivers compounded value through fewer interventions and sharper diagnostics, turning a switch into a sentinel that safeguards your automation’s pulse without fanfare.

The GE IS420ESWBH2A anchors deployments in gas-fired power plants, where it weaves IONet threads for turbine governors and exciters, demanding high-reliability links amid acoustic noise and heat that could fragment signals. Here, in process control environments, its fiber uplinks span control rooms to field cabinets, upholding critical system uptime by queuing diagnostics from vibration arrays without latency spikes—essential for predictive maintenance that dodges overspeed risks.

Venturing into combined-cycle facilities, it facilitates seamless handoffs between steam and gas sections, buffering Ethernet traffic from load-sharing modules in setups chasing peak efficiency. Harsh vibrations from rotating machinery test its mettle, yet it maintains deterministic paths for fast data cycles, integrating with safety PLCs to enforce interlocks sans packet loss.

In renewable-hybrid grids, the switch supports wind-gas balancing, extending IONet to remote SCADA nodes over multi-mode fiber for resilient monitoring. Whether used in power plants or turbine control realms, the GE IS420ESWBH2A delivers the unyielding connectivity that powers adaptive, outage-proof operations.

IS420ESWBH1A – Base model without fiber ports, suited for compact, copper-only IONet segments in smaller turbine setups. IS420ESWBH3A – Upgraded single-mode fiber variant for extended distances up to 40 km in large-scale plant networks.

IS420ESWAH2A – Compact enclosure version with similar port config, ideal for space-constrained hazardous zones.

IS420UPCS1A – Controller module that interfaces directly with ESWB switches for core Mark VIe processing.

IS420SICIH2A – Safety input card add-on, enhancing IONet redundancy when paired with the switch.

IS420EPXAH1A – Exciter power module companion for streamlined turbine excitation loops.

IS420DTAOH1A – Analog output terminal board for expanding I/O tied to switch-managed networks.

Prior to rack-mounting the GE IS420ESWBH2A, a methodical pre-check can avert those mid-commission gremlins that stretch timelines. Confirm IONet compatibility with your Mark VIe controller—scan for firmware alignment via GE’s ToolboxST to dodge handshake failures, and verify the backplane’s slot provisions for its 5.6 cm depth. Airflow clearance is key in turbine halls; budget 50 mm above and below to vent operational warmth, particularly if stacking near heat-generating I/O. Power-wise, inspect your 24 V supply for sag resilience—test under load to ensure it holds above 21 V, as brownouts below that threshold might lock the unit in a reboot loop, necessitating a cycle.

In service, upkeep revolves around observant, low-touch habits that sustain its edge. Weekly LED patrols—focusing on power, link, and speed indicators—catch duplex flips or idle ports early, often traceable to loose RJ-45s in vibrating locales. Biannual connector audits involve reseating LC fibers and torquing Phoenix terminals to 0.5 Nm, guarding against corrosion in humid enclosures; a continuity probe across ports confirms no creeping faults. For thoroughness, annual throughput tests via a packet generator simulate multicast storms, validating buffer holds and failover times under GE’s diagnostic protocols. In ATEX-rated zones, pair this with enclosure IP checks to block ingress. These steps aren’t burdensome—they’re pragmatic guardrails, keeping your network vigilant so you can prioritize turbine tweaks over troubleshooting.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626