Description

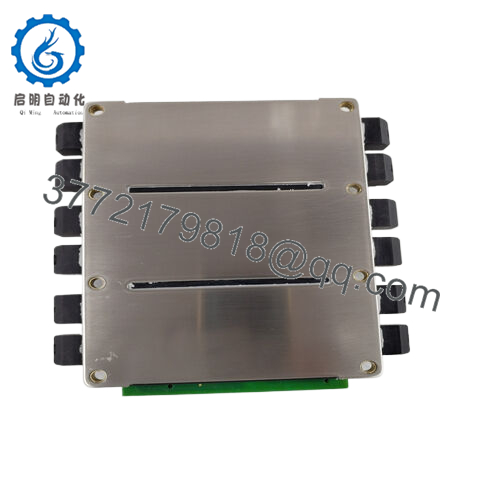

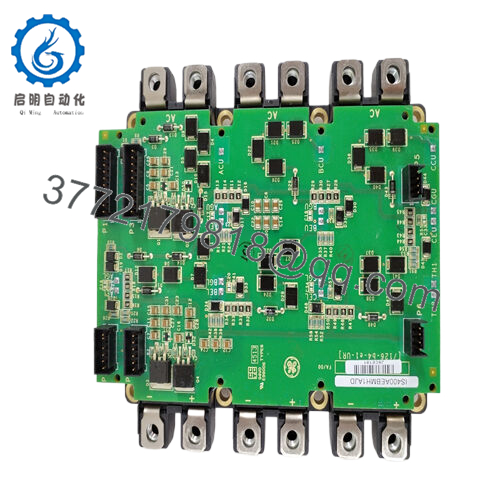

Product Model: GE IS400AEBMH1AJD

- Product Brand: General Electric (GE)

- Product Series: Mark VIe Control System

- Product Features:

- High-performance board for Mark VIe turbine control systems

- Engineered for robust operation in demanding environments

- Full compatibility with GE’s distributed control architecture

- Long-term maintainability and diagnostic support

Product Role & System Fit

The GE IS400AEBMH1AJD is a specialized module designed to operate as part of GE’s advanced Mark VIe control system. Its primary function is to provide reliable control logic and communication pathways within turbine and industrial automation environments. Acting as a bridge between central processors and field-level hardware, it ensures that critical instructions are processed quickly and accurately.

In the architecture of a Mark VIe system, the module fits neatly into a modular rack. This design philosophy allows operators to expand or replace hardware without disturbing the rest of the installation. The GE IS400AEBMH1AJD communicates seamlessly with companion boards, operator interfaces, and field devices, making it a cornerstone in both turbine applications and other high-demand automation systems.

What makes it especially valuable is its compatibility with GE’s distributed control framework. Instead of a single point of failure, the system is designed with redundancy and modularity. The GE IS400AEBMH1AJD contributes to this resilience by offering a dependable interface that supports continuous plant operation.

Applications & Industry Context

Industrial operators often face the challenge of balancing output efficiency with equipment reliability. In the energy sector, where turbines must run continuously to meet grid demand, downtime is unacceptable. The GE IS400AEBMH1AJD plays a critical role in keeping such systems stable.

For example, in gas turbine plants, the module ensures that control logic executes with precision, feeding the right signals to actuators and valves at exactly the right time. This prevents operational instability and contributes to better fuel efficiency. In steam turbine environments, where pressure and temperature control are essential, the module provides the accuracy required to maintain safe limits without sacrificing productivity.

Beyond power generation, industries such as petrochemicals, refining, and heavy manufacturing also rely on this component. These environments are characterized by harsh conditions — from high electrical noise to extreme temperatures — yet the GE IS400AEBMH1AJD is engineered to handle them. The rugged board design and built-in diagnostic capabilities allow it to continue performing even when environmental conditions push lesser hardware to failure.

For operators, the presence of this module means smoother process control, fewer unplanned shutdowns, and ultimately, a safer and more efficient plant.

- IS400AEBMH1AJD

- IS400AEBMH1AJD

Technical Features & Benefits

The GE IS400AEBMH1AJD is more than just a circuit board. It incorporates a range of features that directly translate into operational benefits for plant owners and maintenance teams.

One of the key highlights is its compatibility with the Mark VIe system. Because the Mark VIe architecture emphasizes scalability and modularity, the board can be easily integrated into existing racks with minimal configuration. This reduces engineering time during system expansion or upgrades.

Reliability is another defining characteristic. GE designs its turbine control hardware for continuous duty cycles, meaning the GE IS400AEBMH1AJD can operate year-round with minimal degradation. Protective circuitry helps shield the board from electrical surges and interference, which are common in high-power industrial setups.

From a diagnostic standpoint, the module is designed to work with GE’s monitoring software. This allows maintenance teams to quickly identify faults or anomalies at the board level. Such predictive maintenance capability reduces downtime and allows for repairs before failures escalate.

Lastly, durability is embedded in the physical construction. The board is built with industrial-grade materials and undergoes rigorous testing to ensure it meets GE’s demanding standards. For operators, this translates to fewer replacements, lower long-term costs, and peace of mind in critical applications.

Technical Specifications Table

| Specification | Details |

|---|---|

| Product Model | GE IS400AEBMH1AJD |

| Manufacturer | General Electric (GE) |

| Product Series | Mark VIe Control System |

| Module Type | Control/Processor Module |

| Application | Turbine and industrial automation |

| Integration | Native compatibility with Mark VIe racks |

| Design | Rugged, industrial-grade PCB |

| Diagnostics | Supported via GE system monitoring tools |

| Environmental Tolerance | Resistant to vibration and temperature extremes |

| Mounting | Modular, rack-mounted |

| Industries Supported | Power generation, petrochemical, manufacturing |

| Reliability Standard | High-availability, continuous-duty design |

Installation & Maintenance Insights

Installing the GE IS400AEBMH1AJD is typically straightforward for engineers familiar with GE’s Mark VIe system. The module slides into its rack position, connecting via backplane interfaces to other components. Proper grounding is essential to ensure noise immunity, and engineers should always verify that firmware compatibility aligns with the system’s current configuration.

Cable routing deserves attention, especially in plants with dense wiring. Organized cabling reduces strain on connectors and minimizes potential faults. Following GE’s wiring documentation ensures that inputs and outputs are correctly assigned.

Maintenance practices should include regular system diagnostics through GE’s software interface, which can flag potential board-level issues before they affect operations. Periodic inspection for dust buildup, connector wear, or environmental stress marks also extends module longevity. For facilities with heavy vibration exposure, technicians may consider reseating the module during scheduled maintenance intervals to ensure reliable connections.

By adhering to these guidelines, plants can maximize the operational life of the GE IS400AEBMH1AJD while minimizing unplanned downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626