Description

In the unforgiving landscape of gas turbine operations, where milliseconds separate optimal performance from catastrophic faults, engineers often contend with the fragility of distributed processing that falters under load spikes or sensor overloads, leading to erratic control loops and unplanned scrams. The GE IS220UCSAH1A-C confronts this head-on as a specialized PAMC Acoustic Monitor Processor, engineered to deliver unerring real-time diagnostics in industrial automation setups where acoustic anomalies signal impending blade cracks or combustion instabilities. Envision a heavy-duty combined-cycle plant, where turbine rotors spin at 3,600 RPM amid searing exhaust gases and acoustic barrages—without precise monitoring, subtle vibrations amplify into failures, eroding efficiency and inviting regulatory penalties. Or consider offshore gas compression stations, where corrosive mists and seismic rumbles demand high-reliability safeguards to sustain process control without compromising I/O signal chains.

This is the terrain where the GE IS220UCSAH1A-C shines, prioritizing the user’s quest for system stability by processing acoustic data streams from microphones and accelerometers, flagging deviations that trigger preemptive adjustments before they escalate. In scenarios like retrofitting legacy Mark systems for enhanced predictive maintenance or scaling I/O architectures in wind-integrated grids, it emerges as essential, supplanting generic processors with tailored logic that integrates seamlessly into turbine stacks. Absent such a module, operations lean on disjointed add-ons—off-the-shelf DSP boards or manual inspections—that balloon downtime and expose gaps in modular integration. The GE IS220UCSAH1A-C counters this with embedded algorithms that correlate noise patterns against baselines, fostering proactive interventions in process control environments where high-reliability isn’t optional but foundational.

- IS220UCSAH1A-C

Its consultative depth appeals to deployment teams navigating SIL compliance or hybrid renewables: it anticipates the need for low-latency IONet handshakes, embedding diagnostics that surface acoustic trends via standard HMI overlays. For search-focused pros targeting “turbine acoustic monitoring” or “Mark VIe processor module,” it surfaces as a beacon of targeted resilience. In short, if your automation challenges center on preempting failures through sonic vigilance in high-stakes rotations, the GE IS220UCSAH1A-C redefines those threats as tunable assets, rooted in field-proven precision that informs every upgrade call.

When piecing together a turbine’s neural network, the ideal processor doesn’t just crunch numbers—it orchestrates the symphony of inputs to output harmony under duress, without introducing delays that ripple through the stack. The GE IS220UCSAH1A-C fulfills this as a PAMC Acoustic Monitor Processor in GE’s Mark VIe lineup, dedicated to ingesting raw acoustic signals from field-mounted transducers, applying Fourier transforms and pattern recognition to discern anomalies like rub tones or flutter, then disseminating alerts across the IONet fabric for controller action. It interfaces via Ethernet ports to upstream I/O packs, pulling in synchronized vibration data while pushing processed insights to central UCSC nodes, all within a deterministic 1 ms cycle to honor triple-redundant topologies.

Nestled in the core processing tier of the automation hierarchy, it dovetails with backplane assemblies to bridge sensor arrays to supervisory layers like SCADA or CIMPLICITY HMIs, supporting protocols such as Ethernet/IP for multicast diagnostics or Modbus for legacy tie-ins. Redundancy is intuitive here: dual-channel memory mirroring ensures failover transparency, with onboard watchdogs resetting errant threads without loop drops, while QNX Neutrino’s real-time kernel juggles concurrent tasks—from acoustic filtering to event logging—sans jitter. In hybrid setups, it extends to wind turbine nacelles, where it syncs with exciters for aero-acoustic profiling, leveraging its Freescale PowerQUICC core to handle 667 MHz bursts without thermal throttling.

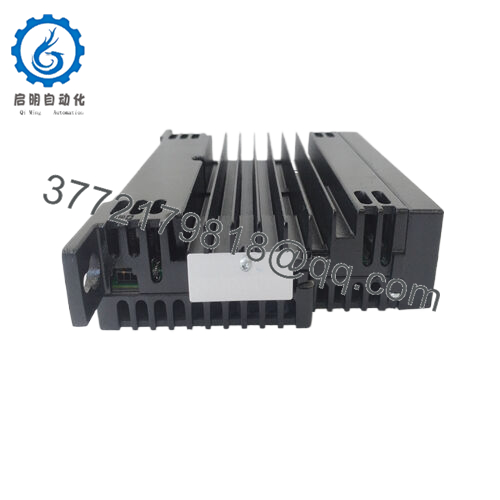

From a deployment lens, integration unfolds methodically: latch it into a standard Mark VIe cabinet via rear screw mounts, connect the RJ-45 IONet daisy-chain, and calibrate baselines using ToolboxST— no exotic tools needed, though verifying firmware parity with the host controller averts sync hiccups. It thrives on 18-36 V DC feeds, drawing a lean 12 W to minimize cabinet heat, and its grill-vented enclosure promotes passive cooling in ambient up to 65°C. The GE IS220UCSAH1A-C transcends rote computation; it’s a vigilant interpreter in your system’s dialogue, anticipating acoustic cues to fortify the broader control weave against the unforeseen.

| Specification | Details |

|---|---|

| Model Number | IS220UCSAH1A-C |

| Brand | GE |

| Type | PAMC Acoustic Monitor Processor |

| Input Voltage | 18-36 V DC |

| Operating Temp Range | 0°C to 65°C |

| Mounting Style | Panel mount with rear screws |

| Dimensions | 16 cm x 16 cm x 12 cm |

| Weight | 0.8 kg |

| Interface/Bus | Ethernet IONet, RJ-45 |

| Compliance | CE, UL, ATEX Zone 2 |

| Supported Protocols | Ethernet/IP, Modbus |

| Typical Power Draw | 12 W |

Deploying the GE IS220UCSAH1A-C infuses your turbine oversight with a predictive acuity that pays off in spades, beginning with its engineered vigilance over acoustic signatures that averts the stealthy creep of mechanical distress. In relentless cycles where harmonics from imbalanced rotors could prelude a million-dollar overhaul, its real-time spectral analysis locks in performance consistency, queuing interventions that sidestep full stops and reclaim lost megawatts—often boosting availability by 2-5% in monitored fleets. This isn’t mere detection; it’s the foresight that lets ops teams calibrate fuel flows or vane angles preemptively, honing efficiency without the guesswork of post-event forensics.

Maintenance workflows lighten considerably too, as integrated self-tests cycle through memory scrubs and signal integrity checks, surfacing wear on mic preamps via LED codes or network broadcasts before they mute critical bands. Integration’s subtlety shines in expansions—pairing with existing IONet spines demands no rewiring overhauls, slashing engineering overhead for sites layering renewables onto gas bases. Long-term, this module’s robust QNX footing and low MTBF ensure it weathers EMI-laced enclosures, prolonging system cohesion and easing audits under ISO 61508 mandates.

At heart, the GE IS220UCSAH1A-C cultivates reliability as an ecosystem enabler, where acoustic insights feed broader analytics to refine load-sharing or emissions profiles. For the engineer charting a retrofit, it trims the fat from traditional monitoring rigs, delivering acoustic precision that amplifies overall resilience without inflating complexity— a understated powerhouse turning sonic whispers into operational thunder.

The GE IS220UCSAH1A-C deploys adeptly in gas turbine halls of utility-scale plants, where it scrutinizes combustion chambers for erratic noise patterns amid 1,500°C infernos and pressure waves, bolstering process control environments with high-reliability diagnostics that enforce protective trips in under 100 ms—key for upholding critical system uptime during peak demands or fuel switches.

In steam turbine setups within nuclear or coal facilities, it anchors acoustic arrays on low-pressure casings, sifting through steam whistles and blade pass frequencies to flag erosion early, thriving in humid, vibration-riddled confines that demand continuous uptime for baseload stability. Its IONet prowess shines here, fusing data with vibration modules for holistic health scoring that curbs forced outages.

Extending to oil and gas compression trains, the module embeds in skid-mounted controls for centrifugal compressors, parsing surge precursors via suction dynamics in explosive atmospheres. Whether used in power plants or turbine control environments, the GE IS220UCSAH1A-C underpins fast data cycles in harsh conditions, ensuring acoustic sentinels guard against the unseen forces that threaten yield.

IS220UCSBH1A – Enhanced variant with expanded memory for multi-turbine acoustic fusion in larger Mark VIe arrays.

IS220UCSC1A – Core controller companion for triple-redundant IONet orchestration alongside PAMC processing.

IS220PDIAH1A – Discrete input module that feeds acoustic triggers into the UCSAH1A-C for interlock validation.

IS220PPDAH1A – Power distribution add-on ensuring stable feeds to acoustic processors in remote turbine installs.

IS220ESWBH3A – Fiber-extended Ethernet switch for linking PAMC units across distributed control spans.

IS420UCSCH1A – Higher-spec UCSC alternative for safety-critical acoustic monitoring in SIL 3 loops.

IS220YAICS1A – Analog safety I/O pack integrating with UCSAH1A-C for vibration-acoustic hybrid inputs.

Before energizing the GE IS220UCSAH1A-C in your cabinet, a targeted compatibility audit can forestall those elusive startup quirks that cascade into delays. Cross-check IONet firmware against the host UCSC via GE’s compatibility ledger—version mismatches often manifest as dropped packets during acoustic polling, so stage a bench sim with a spare transducer loop. Enclosure dynamics warrant scrutiny too; in turbine bays with ambient spikes, confirm 25 mm vent gaps around the grill to sustain passive cooling, and probe the 18-36 V rail for ripple under 500 mV to prevent processor brownouts. Ground the chassis solidly to chassis earth, as floating potentials amplify noise in mic lines, skewing baselines from the outset.

In operation, stewardship emphasizes discerning vigilance over rote patrols. Fortnightly status LED sweeps—green for nominal, amber for self-test flags—pinpoint memory faults or IONet drifts, frequently before they echo in logs. Semiannual connector audits on RJ-45s and power terminals, torqued to 0.6 Nm, mitigate loosening from acoustic thrum; include a continuity tickle on transducer cables to catch insulation pinholes. Yearly, invoke full-spectrum cal via ToolboxST, injecting test tones to benchmark FFT accuracy against OEM curves—pair with QNX kernel scans for patch currency. In coastal or dusty sites, a dry microfiber swipe over vents quarterly bars ingress without risking static. These protocols aren’t onerous; they’re honed to your turbine’s cadence, preserving acuity while redirecting focus to strategic tuning over triage.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626