Description

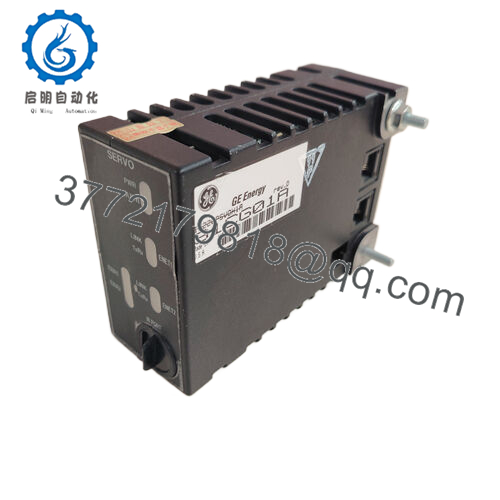

Product Model: GE IS220PSVOH1A

Product Brand: GE (General Electric)

Product Series: Mark VIe

Key Features:

- High-precision servo valve output control for turbine applications

- Robust Mark VIe platform integration with advanced diagnostics

- Ruggedized design for harsh industrial environments

- Simplified installation and configuration via Ethernet communication

Applications & Industry Context

Across the landscape of heavy industrial automation, few environments demand as much precision and reliability as gas and steam turbine control systems. The GE IS220PSVOH1A plays a pivotal role in these settings, serving as the servo valve output interface that directly governs actuator movement. From power generation plants in the Middle East to combined-cycle facilities in North America, this module helps engineers maintain exact control over fuel flow, inlet guide vane positioning, and hydraulic actuators.

In practical operation, turbine servos respond to microsecond-level control signals. Any delay or inconsistency can affect combustion efficiency or rotor stability. The GE IS220PSVOH1A ensures that servo commands are transmitted with exceptional fidelity, maintaining a synchronized relationship between the turbine controller and mechanical components.

Industries such as oil & gas, energy utilities, and process plants rely heavily on the Mark VIe control ecosystem. The IS220PSVOH1A integrates seamlessly with that architecture, providing reliable communication through Ethernet-based I/O networks. Field engineers appreciate its predictable performance even under thermal stress, humidity fluctuations, or electrical noise — conditions that would degrade lesser control modules.

In refineries, for instance, where turbine-driven compressors must run continuously, downtime translates to significant financial loss. The GE IS220PSVOH1A minimizes such risk through built-in redundancy support and robust diagnostics. These characteristics make it a trusted element in mission-critical turbine applications, where safety, efficiency, and continuous operation define success.

- IS220PSVOH1A

- IS220PSVOH1A

Technical Features & Benefits

What sets the GE IS220PSVOH1A apart from conventional servo output boards is its blend of rugged construction, precision control, and intelligent diagnostics. Designed under GE’s Mark VIe architecture, the module combines high-speed digital signal processing with fault-tolerant hardware layers. Each output channel provides stable current or voltage signals to servo actuators, ensuring responsive valve control even under variable load conditions.

One notable feature is its modular design philosophy. The Mark VIe platform encourages flexible configuration — whether you’re managing a single turbine section or a full plant-wide system, modules like the IS220PSVOH1A slot easily into standardized terminal boards. This modularity simplifies both initial commissioning and future scalability.

Electrical engineers often highlight the self-diagnostic capability of this module. It continuously monitors output signal integrity, temperature, and internal communication status. In the event of a deviation, alarms can be relayed back to the controller through the system’s Ethernet network, allowing technicians to pinpoint and resolve issues before they escalate.

Another major advantage is signal isolation. Each servo output channel is optically and galvanically isolated, preventing ground loops and interference — a frequent issue in high-current servo systems. This ensures consistent, noise-free operation, especially in environments with large electromagnetic interference sources such as generator stators or high-voltage switchgear.

Additionally, the GE IS220PSVOH1A supports hot-swap functionality when configured within redundant I/O racks. This feature allows maintenance crews to replace or test modules without halting the turbine control sequence, dramatically reducing downtime. Combined with GE’s global technical support and long product lifecycle, this module represents a solid long-term investment for operators seeking reliability and maintainability.

Technical Specifications

| Specification | Description |

|---|---|

| Product Model | GE IS220PSVOH1A |

| Brand | GE (General Electric) |

| Series | Mark VIe Control System |

| Function | Servo Valve Output Module |

| Communication Interface | Ethernet (10/100 Mbps) |

| Number of Channels | 2 independent servo output channels |

| Signal Types | Current/voltage servo drive signals |

| Isolation | Optical and galvanic isolation per channel |

| Power Supply | 28 VDC nominal |

| Operating Temperature | –30°C to +65°C |

| Mounting | DIN rail or panel mount via terminal board |

| Diagnostics | Built-in signal monitoring and fault reporting |

| Hot-Swap Capability | Supported in redundant configurations |

| Dimensions | Approx. 4.5 x 7.5 inches |

| Weight | 0.45 kg (approx.) |

Product Role & System Fit

Within the Mark VIe ecosystem, the GE IS220PSVOH1A serves as the primary output module for servo-controlled devices such as hydraulic actuators, valve positioners, and electro-hydraulic governors. It acts as a bridge between the control logic processed in the main controller (like the Mark VIe Control Processor) and the physical actuation mechanism in the field.

This integration follows GE’s distributed I/O design principle. Rather than routing all signals through a centralized chassis, each I/O module — including the IS220PSVOH1A — resides close to the field devices. This reduces wiring complexity and improves noise immunity. The module communicates digitally through Ethernet Global Data (EGD), ensuring deterministic real-time control.

Compatibility extends to various Mark VIe terminal boards such as the IS200STAIH2A or IS200SPROH2B, depending on the desired signal interface. In many installations, the IS220PSVOH1A is paired with servo drivers controlling fuel valves, inlet guide vanes, or bypass dampers. Its precision output helps maintain turbine stability during startup, load transitions, and shutdown sequences.

Another noteworthy aspect is backward compatibility. Although engineered for the Mark VIe, the GE IS220PSVOH1A can often replace older servo modules (like IS200SVROH1A) with minor configuration updates, offering a cost-effective upgrade path without major rewiring. This compatibility ensures that operators maintaining legacy GE turbine systems can adopt modern I/O reliability while preserving existing plant architecture.

Installation & Maintenance Insights

Field engineers often note how straightforward it is to deploy the GE IS220PSVOH1A compared to earlier Mark VI components. Installation begins by ensuring that the correct terminal board (typically an STVO board) is in place. Once mounted, the module simply connects through the plug-and-play interface. Ethernet cabling links it to the control network, automatically recognizing its role within the Mark VIe system configuration.

For maintenance teams, accessibility is a key benefit. The module’s front LED indicators display power status, communication health, and channel operation, enabling at-a-glance troubleshooting. During commissioning, using GE ToolboxST software allows engineers to calibrate and verify output signals, ensuring the servo actuators respond accurately.

When performing hot-swap replacement, technicians are advised to confirm redundant control coverage before removing the existing module. Thanks to built-in self-identification, the IS220PSVOH1A automatically uploads configuration parameters once reinserted, minimizing manual setup. This level of serviceability helps keep turbines online during routine maintenance — a major advantage in plants where every minute of uptime counts.

To preserve long-term reliability, GE recommends periodic inspection of Ethernet connectors and ensuring environmental cleanliness inside the control cabinet. Given its wide thermal tolerance and rugged build, this module rarely fails under normal operating conditions, but preventive checks on cabling and terminal tightness can further extend its life.

Related Models

- IS220PDOAH1A – Discrete Output Module with high-speed digital channels

- IS220PAICH1B – Analog Input Module for process variable monitoring

- IS220PRTDH1A – RTD Input Module for temperature sensing

- IS220PSCAH1A – Power Supply Control Module for Mark VIe racks

- IS220UCSAH1A – Universal Control Server Module

- IS200STAIH2A – Analog Terminal Board compatible with servo modules

- IS200SPROH2B – Servo Terminal Board variant for dual-channel operation

- IS220PAOCH1B – Analog Output Module for actuator control applications

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626