Description

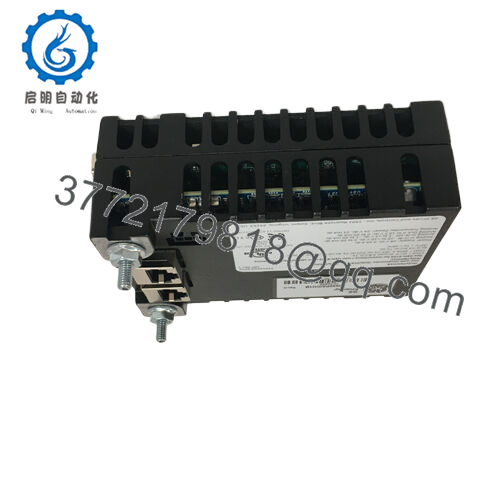

GE IS220PAICH1B, as a specialized analog input module, plays an important role in industrial automation architecture. It is connected to various analog sensors such as temperature sensors, pressure transmitters, and flow meters, and converts the analog signals of these sensors into digital data for higher-level control systems such as programmable logic controllers (PLCs) or distributed control systems (DCS) to process.

IS220PAICH1B

This module is equipped with multiple analog input channels, each capable of processing a specific range of input signals ranging from millivolts to volts. It uses a high-resolution analog-to-digital converter (ADC) with a resolution of up to 16 bits, ensuring accurate signal conversion and even detecting the smallest signal changes. The built-in signal conditioning circuit can filter out noise and interference, amplify weak signals, and linearize the output of nonlinear sensors to ensure that the data transmitted to the control system is clean and reliable.

IS220PAICH1B

Technical specifications:

Model IS220PAICH1B

Brand General Electric

Type Analog Input Module

Input voltage range 0-10V, ± 10V, 0-20mA, 4-20mA

Resolution 16 bits

Working temperature range -40 ° C to+70 ° C

Installation method: DIN rail

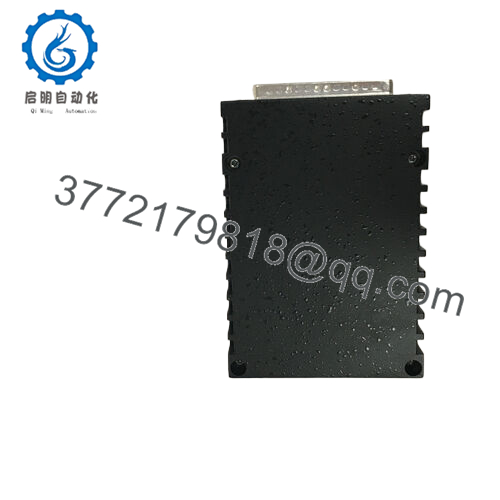

Size 100mm x 80mm x 60mm

Weight 0.45 kg

Interface/Bus RS-485, Ethernet (optional)

Certification CE, RoHS, IEC 61000-6-2

Supports Modbus RTU and Modbus TCP protocols (optional)

Typical power consumption 5W

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

IS220PAICH1B

Main features and advantages:

IS220PAICH1B communicates with the control system through a high-speed serial bus (such as RS-485 or Ethernet, depending on the system configuration). It supports industry standard communication protocols such as Modbus RTU or Modbus TCP, which can be seamlessly integrated with existing automation systems. This module also has diagnostic functions, continuously monitoring the status of each input channel, detecting abnormal situations such as sensor failures, signal loss, or out of range, and reporting these events to the control system for timely troubleshooting.

From a physical structure perspective, GEIS220PAICH1B is designed for easy installation in standard industrial control cabinets. Its compact size and DIN rail installation method save valuable space, and modular design facilitates replacement and maintenance. Whether used for new automation projects or as an upgrade to existing systems, this module can seamlessly integrate into the industrial control ecosystem, improving the overall accuracy and reliability of analog input data acquisition processes.

The advanced signal conditioning function and high-resolution ADC of this module ensure accurate and consistent data obtained from sensors, thereby achieving more precise process control and improving product quality. For example, in chemical processing plants, using IS220PAICH1B to accurately measure temperature and pressure can help optimize reaction conditions, reduce waste, and increase the yield of chemical products.

The module’s sturdy and durable design, as well as excellent anti-interference ability, make it suitable for harsh industrial environments. It can withstand extreme temperatures, vibrations, and electrical noise, ensuring reliable operation even under the most demanding conditions. This makes it an ideal choice for applications in industries such as oil and gas, mining, and manufacturing, where reliability and durability are crucial.

The wide sensor compatibility and flexible communication options ofIS220PAICH1B simplify system integration and reduce engineering costs. It can be connected to various analog sensors without the need for additional signal conditioning modules, saving costs and shortening installation time. Its support for standard communication protocols enables it to easily integrate with existing control systems, achieving seamless data exchange and control.

In addition, the diagnostic function of this module helps to achieve proactive maintenance, reduce downtime, and improve system availability. By continuously monitoring the status of each input channel, it can detect potential problems before they lead to malfunctions, allowing maintenance teams to schedule repairs during planned downtime and avoid costly unexpected interruptions in production.

IS220PAICH1B

Application areas:

In the power industry, this module is used to monitor and control the operation of generators, turbines, and other power related equipment. It can measure parameters such as voltage, current, frequency, temperature, and pressure, providing real-time data for control systems to achieve efficient power production and grid management. For example, in thermal power plants, IS220PAICH1Bcan be used to measure the temperature of boiler water and steam, ensuring that the boiler operates within safe and efficient parameter ranges.

In the manufacturing industry, this module is used for automated production lines to monitor and control various process variables such as temperature, pressure, flow rate, and liquid level. It can be integrated with sensors on production equipment such as robotic arms and CNC machines to achieve precise control of the manufacturing process and ensure product quality. For example, in food and beverage production plants, GEIS220PAICH1Bcan be used to measure temperature and pressure during cooking and packaging processes, ensuring product safety and compliance with required quality standards.

In the water and wastewater treatment industry, this module is used to monitor and control treatment processes such as filtration, disinfection, and chemical dosing. It can measure parameters such as water flow rate, pH value, turbidity, and dissolved oxygen, providing real-time data for the control system to achieve efficient treatment and management of water resources. For example, in wastewater treatment plants, IS220PAICH1B can be used to measure the flow rate of wastewater entering the treatment plant and the amount of chemical agents added during the treatment process, ensuring that the treatment process is optimized and the treated water meets discharge standards.

IS220PAICH1B

Related products:

GE IS210PAICH1A: Low resolution, limited input channels, suitable for less complex analog input applications.

GE IS220PAICH2B: With more input channels and enhanced signal conditioning capabilities, designed specifically for higher demand industrial automation projects.

GE IS220PAICH1C: equipped with basic analog input function, suitable for small industrial applications with limited budget.

GE IS230PAICH1B: The next generation analog input module, with advanced functions such as wireless connection and edge computing, is suitable for intelligent manufacturing and industrial 4.0 applications.

GE IS220PAICH1D: IS220PAICH1B has enhanced environmental protection capabilities and is designed specifically for harsh industrial environments such as offshore platforms and mining sites.

IS220PAICH1B

Installation and maintenance:

Before installing GE IS220PAICH1B, it is essential to ensure that the power supply meets the requirements of the module. Check the voltage level to ensure there are no fluctuations or surges that may damage the module. In addition, it is necessary to verify the compatibility of the communication interface with the existing control system. Ensure that the communication protocol is configured correctly and the network settings are correct.

During the installation process, be careful when operating the module to avoid damage from static electricity. Install and wire correctly according to the manufacturer’s instructions. Ensure all connections are secure and modules are properly grounded to prevent electrical interference. When connecting analog sensors to modules, use appropriate cables and connectors, and follow recommended cable lengths and shielding practices to ensure reliable signal transmission.

For daily maintenance, regularly check the status indicator lights on the module to monitor its operation. Green light indicates normal operation, while red light may indicate a fault or error state. Regularly check communication cables and power connections for signs of wear or damage. Gently clean the surface of the module to remove any accumulated dust or debris. It is also recommended to regularly calibrate the module using a calibration signal source to ensure the accuracy of analog input measurements. Download and install the latest firmware updates from the official GE website to keep the module firmware up-to-date. These updates typically include error fixes, performance improvements, and security enhancements to ensure that the module always operates at its best.

Other GE product models:

GE HE693THM888K

GE IS420EWSBH3A

GE IS200TREAS1A

GE IC695CPE305

GE F650BFBF1G0HI6E

GE VMIVME-5565-110000

GE IC695CPU315-CD

GE IC695NKT002

GE IC695CPU315-CD

GE IS200TDBTH6ABC

GE IC800SSI228RD2

GE TKMA3Y1200

GE IS210MACCH1AKH

GE IS210BPPBH2CAA

GE IS210MACCH1AGG

GE IS200AEPCH1BAA

GE IS200WEMAH1AEA

GE IS200AEPAH1AHD

GE IS200WETAH1AEC

GE VMIVME-5565-010000 332-015565-010000 P

GE IC695ALG508-AA

GE DS200CPCAG1ABB

GE DS3800HFPB1F1E

GE DS3800NB1A

GE IC695ALG508

GE IC695ALG508

GE MIVII1000E00HI00

GE IC758CSWC19PCX512

GE XMTC-6C-11

GE WPX-08 WE3DNQGQEXBBXCX

GE 750-P5-G5-S5-HI-A20-R-E

GE 469P5HIA20EH

GE IC694PWR330

GE IC200ALG262

GE CK10CE300

GE IC755CBW07CDA

GE IS220PTURH1B

GE IS220PTURH1A

GE IS420UCSBS1A

GE IS200TDBSH6ABC

GE IS200STAIH1ABB

GE IS200SRTDH1ABB

GE IS420ESWB3HA

GE IS200JPDFG1A

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626