Description

The GE IS215WETAH1A is widely used in industrial automation, particularly within the wind turbine sector as part of GE’s Mark VIe control system family. It plays a vital role in managing analog and digital signal inputs and outputs for turbine control, especially in advanced wind turbine applications. This module is designed to address challenges like precise instrumentation signal handling and robust field communication, which are essential in optimizing wind turbine operations across various environmental conditions.

Applicable in wind farms and renewable energy installations, the GE IS215WETAH1A enables operators to maintain efficient turbine control and real-time data integration required for maximizing energy output and ensuring safety. Its support for configurable analog/digital channels and HART communication protocols underscores its adaptability for process control systems and turbine diagnostics. The module is essential in wind turbine automation where exact control of pitch, speed, and electrical parameters sustains reliable power generation and operational longevity.

- IS215WETAH1A

- IS215WETAH1A

Product Introduction and Positioning

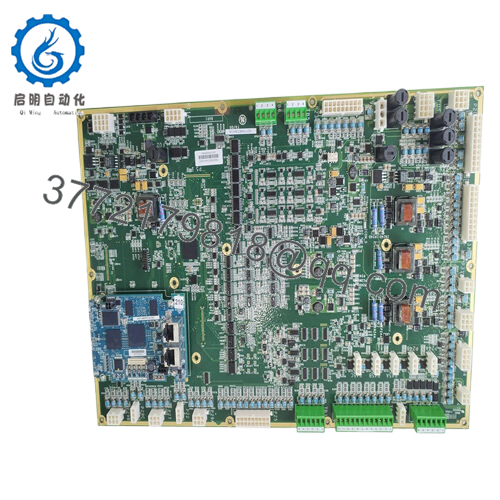

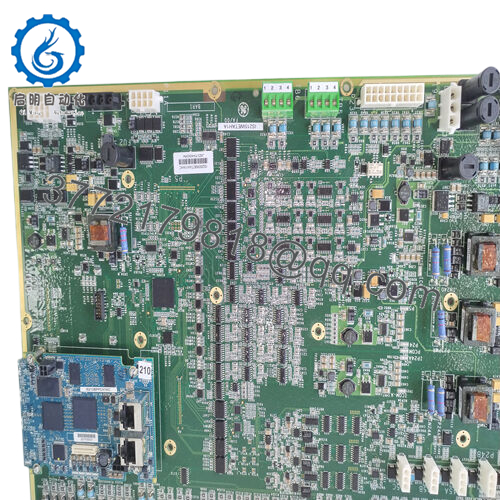

The GE IS215WETAH1A is an analog and digital I/O module within the Mark VIe turbine control system designed specifically for wind turbine applications. It manages 16 to 32 configurable analog and digital channels, handling signals like 4–20 mA, 0–10 V, RTD inputs, and 24 VDC dry or wet contacts. This module’s flexible channel configuration allows it to accommodate diverse field instrumentation and control demands, making it a cornerstone of effective wind turbine control solutions.

Integrated seamlessly into the Mark VIe architecture, the GE IS215WETAH1A provides precise control and monitoring of turbine subsystems through reliable data acquisition and output commands. It enhances system modularity and scalability, allowing engineers to tailor control strategies for different turbine models and site conditions. For system integrators, its rugged design and compatibility with industry communication standards simplify the installation and maintenance processes while ensuring a high degree of operational reliability.

Key Technical Features and Functional Benefits

The GE IS215WETAH1A excels through its versatile channel support, allowing 16 to 32 mixed analog and digital input/output configurations suited for complex turbine control schemes. It supports industry-standard signal types including current loops (4–20 mA), voltage signals (0–10 V), and resistor temperature detectors (RTDs), providing flexibility to manage various sensor and actuator interfaces. The integration of HART communication enhances device diagnostics and field device parameter adjustments without system interruption.

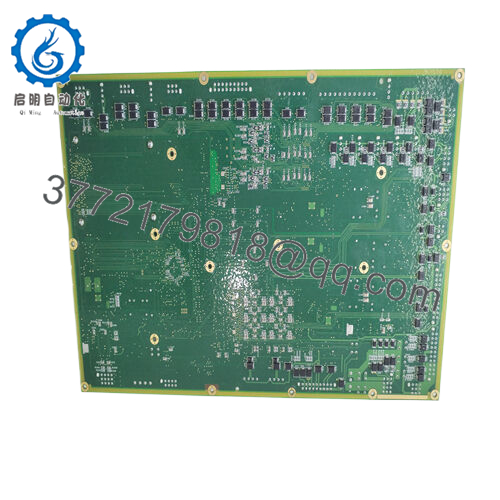

Engineered for durability, the module withstands an industrial temperature range and environmental stresses typical of wind turbine nacelles and control cabinets. Its compact form factor supports efficient space utilization in control racks while maintaining easy access for wiring and diagnostics. Reliability is reinforced by design features that minimize susceptibility to electrical noise and mechanical vibration, ensuring stable operation in dynamic and sometimes unpredictable wind farm environments.

Detailed Technical Specifications

| Parameter | Value |

|---|---|

| Model | GE IS215WETAH1A |

| Brand | General Electric (GE) |

| Product Type | Analog/Digital I/O Module (Mark VIe Wind) |

| Channels | Configurable 16–32 analog/digital channels |

| Analog Input Types | 4–20 mA, 0–10 V, RTD |

| Digital Input Types | 24 VDC dry/wet contacts |

| Mounting | DIN Rail or Panel Mounting |

| Operating Temperature | Industrial range (-40°C to +70°C) |

| Dimensions | Standard Mark VIe module size |

| Weight | Lightweight PCB assembly |

| Communication | HART protocol support |

| Diagnostics | Built-in communication diagnostics |

| Certifications | Industry-standard wind turbine automation certifications |

Related Modules or Compatible Units

IS220PHRAH1A – HART Analog I/O pack supporting complex analog signal communication in Mark VIe systems.

IS215AEPSG1A – Power supply board providing stable power for critical Mark VIe control modules.

IS420ESWBH3A – Industrial Ethernet switch facilitating high-speed network communication for turbine controllers.

IS230JPDGH1B – DC power distribution module vital for reliable 28V power delivery in control cabinets.

IS215WETAH1CA – Wind turbine top box module working alongside the IS215WETAH1A for expanded control functionality.

Installation Notes and Maintenance Best Practices

Before installing the GE IS215WETAH1A, verify that the control cabinet layout allows DIN rail or panel mounting with appropriate access for analog and digital wiring. Ensure that cable shielding and grounding practices are followed to prevent electrical noise interference, which can affect sensitive signal integrity. Confirm compatibility with existing Mark VIe system modules and use manufacturer-recommended cabling practices to facilitate consistent HART communication.

Routine maintenance should include visual inspections of connectors and wiring to identify corrosion or wear that could impact signal quality. Use system diagnostic tools regularly to verify communication health and channel performance. Firmware and device parameter updates should be performed by trained technicians to maintain optimal control and diagnostic capabilities. Proper environmental controls within the cabinet, such as temperature and humidity regulation, will help extend module longevity and reduce downtime.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626