Description

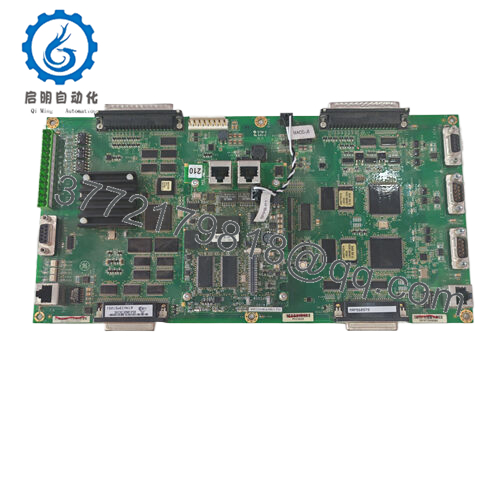

Product Model: IS210MACCH1AKH

Product Brand: GE (General Electric)

Product Series: IS210 / Mark VIe Control Modules

Product Features:

- Main control / processing module used in GE Mark VIe systems

- Executes control algorithms, coordinating I/O and system functions

- Designed for redundancy and high availability

- Rugged construction for industrial environments

Applications & Industry Context

Large industrial plants—power generation, petrochemical, gas turbine installations, and heavy manufacturing—demand precise, reliable control of processes with tight real-time constraints. The IS210MACCH1AKH finds its home in these environments within GE’s Mark VIe automation systems as a core processing module. It handles control logic, oversees safety interlocks, and integrates with I/O modules to maintain system stability.

In a gas turbine plant, for instance, control loops for speed, temperature, fuel flow, and steam valves must operate in concert. The IS210MACCH1AKH processes all these signals, ensures real-time coordination, handles alarming logic, and manages redundancy. In refineries or chemical plants, similar demands exist—control loops, safety interlocks, predictive maintenance, and high availability benefit from a robust module like this.

Because many facilities still run legacy control systems or hybrid architectures, the module’s ability to integrate with existing GE Mark-series systems is crucial. Operational staff often comment that once it’s installed and tested, the IS210MACCH1AKH “just runs” — rarely needing intervention unless a system-level change occurs.

Product Role & System Fit

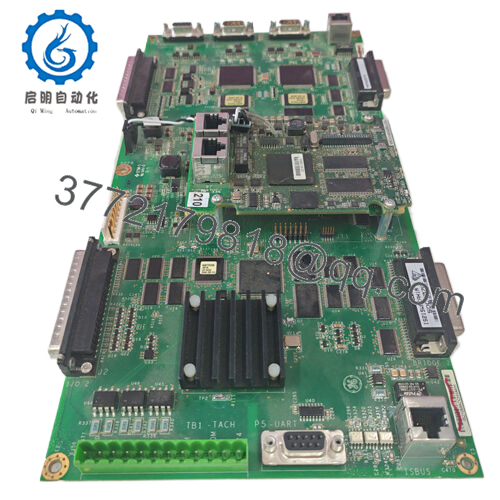

The IS210MACCH1AKH is not merely an I/O card—it is the main control / processing board (often referred to as MACCH module) in the GE Mark VIe control architecture. It manages the execution of control programs, communicates with I/O modules, handles redundancy logic, and interfaces with higher-level system functions (HMI, historian, diagnostics).

Within a control rack or chassis, the IS210MACCH1AKH sits at the heart. It may coexist with signal cards, protection cards, and communication modules. In redundant configurations, dual or triple modules can be employed so failure of one channel doesn’t degrade control. The module’s architecture supports hot-swapping or fallback strategies depending on system setup.

Its integration is made easier by compatibility with the Mark VIe backplane and communication links. It orchestrates packet traffic, oversees system health, and ensures synchronization across control loops. When upgrading or maintaining systems, replacing an IS210MACCH1AKH module is often one of the primary tasks, so designing for safe replacement is a key consideration.

- IS210MACCH1AKH

Technical Features & Benefits

Though technical details on this module are partially proprietary, available sources and typical architecture provide insight into its strengths:

- High-Performance Processing

The IS210MACCH1AKH runs a modern control CPU (often 32-bit RISC or equivalent) capable of executing control logic, coordination, and diagnostics in real time with low latency. - Redundancy & Fault Tolerance

The module is designed to work in redundant configurations, enabling continued operation even if one instance fails. This is vital in power plants or process units where downtime is extremely costly. The board supports failover and continuity logic. - Integrated Diagnostics & Health Monitoring

Built-in self-checks, logging of anomalies, and real-time status reporting help operators detect degraded conditions before they escalate. This capability acts as an early warning system for control faults. - Industrial-Grade Design

The IS210MACCH1AKH is built to withstand harsh conditions: wide operating temperature ranges, vibration, EMI immunity, and robust connectors. Such resilience is necessary in turbine halls, generator rooms, or process plants. - Seamless Mark VIe Ecosystem Compatibility

Because it’s a native GE Mark VIe module, it works smoothly with I/O cards, protection modules, communication units, and software tools in that ecosystem. For plants already standardized on GE, this lowers integration risk. - Scalable & Upgradeable

As plant control needs evolve, the module supports updates—both firmware and configuration. This scalability lets operators expand control complexity without needing to redesign the entire control rack.

From a user perspective, these features translate into fewer interruptions, easier maintenance, consistent performance, and longer life cycles. A well-implemented IS210MACCH1AKH means control logic remains stable under stress, and troubleshooting enters the domain of system engineers—not emergency repair.

Technical Specifications Table

| Specification | Detail / Approximate Value |

|---|---|

| Model | IS210MACCH1AKH |

| Brand | GE (General Electric) |

| Series | IS210 / Mark VIe |

| Module Role | Main Control / Processing (MACCH) |

| Redundancy Support | Simplex, dual, possibly triple (depending on system) |

| Diagnostic Features | Self-checks, error logging, status flags |

| Operating Environment | Industrial (vibration, EMI, temperature) |

| Mounting / Integration | Backplane / rack mount within Mark VIe chassis |

| Power Supply Requirements | According to GE’s control architecture (often 24V DC or compatible internal rails) |

| Communication Links | Internal control bus (Mark VIe backplane), possibly ethernet/communication module interfaces |

| Memory / Firmware | Internal flash or programmable memory for control logic |

| Interfaces with I/O modules | Full compatibility with GE’s I/O, protection, and signal cards |

| Dimensions / Physical Form | Similar to other IS210 / Mark VIe module formats |

| Reliability & Lifetime | Designed for long service life in industrial systems |

Note: Because GE does not publicly release full internal spec sheets for all modules, the above values are based on typical design architectures and industry practice for GE’s IS/Mark VIe modules.

Installation & Maintenance Insights

Proper installation and maintenance are crucial for getting the best from the IS210MACCH1AKH.

Mounting & Environment

Place the module firmly into the correct slot in the Mark VIe chassis or backplane. Ensure it is protected from excessive dust, oil, or corrosive atmospheres. Maintain thermal ventilation and avoid direct exposure to heat sources. Ensure vibration damping in heavy equipment areas.

Power & Grounding

Provide stable, clean power rails as per the system design (e.g., 24 V DC or internal derived voltages). Grounding is critical; poor ground or common-mode interference can induce logic errors. All shields, signal grounds, and control grounds should return to a single bonding point to avoid loops.

Firmware / Configuration

When installing or replacing, ensure the control logic becomes loaded correctly and that firmware versions match those of complementary modules. Backup existing configurations and program images before inserting or removing modules. Where hot-swap is supported, follow manufacturer procedures to avoid logic misalignment.

Diagnostics Checks

After installation, perform functional tests: confirm communication with I/O cards, validate logic operation in test mode, check status flags, and monitor for error diagnostics. Running a controlled simulation or test can expose issues early.

Periodic Maintenance

- Inspect connectors, signal cables, and backplane contacts for corrosion or loosening.

- Check module LEDs or indicator flags for warnings.

- Update firmware during scheduled windows to benefit from stability fixes (if available from GE or authorized vendors).

- In redundant systems, periodically test failover behavior to ensure continuity in real fault conditions.

Replacement & Spares Strategy

Because plants often operate continuous processes, having a preconfigured IS210MACCH1AKH as a spare can drastically reduce repair times. Match firmware, configuration, and hardware revision to the running modules so swapping is nearly plug-and-play. In critical systems, ensure spare stock is kept, and test replacement periodically.

An anecdote: in a power plant, a control logic module failed during a non-shutdown period. The maintenance team inserted a pre-programmed spare IS210MACCH1AKH, and within minutes the system recovered full control functionality. The redundancy and spare strategy saved hours of downtime and avoided process disruption.

Related Models & Alternatives

- IS210MACCH1AKL – variant ruggedized for hazardous environments

- IS210MACCH1AGG – earlier or alternative revision in the same family

- IS210PCLCH1AK – companion I/O extension card often paired with MACCH modules

- IS210UCPCH1AK – module handling I/O bus control, working in tandem with MACCH

- IS200 series modules – earlier generation control / I/O modules, sometimes used in older Mark setups

- Mark VIe CPU modules – higher-level logic controllers that interface with MACCH modules

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626