Description

In the high-stakes orchestration of gas and steam turbine fleets, where balance-of-plant auxiliaries like lube oil pumps, cooling fans, and fuel forwarding systems must hum in lockstep with core generation—yet falter under transient surges, sensor noise, or power glitches that spawn cascading interlocks or efficiency dips—engineers grapple with the fragility of decentralized logic that fragments oversight and inflates fault recovery windows. The GE IS210BPPBH2BMD addresses this as a pivotal BOP processor board within GE’s Mark VI Speedtronic ecosystem, a compact controller engineered for industrial automation to centralize auxiliary sequencing and protection in process control frameworks. Consider a combined-cycle plant throttling steam dumps: auxiliary relays chatter amid voltage sags, but without a unified BOP hub, those signals splinter, delaying pump startups and risking bearing dry-outs that escalate to multimillion-dollar scrams. This board counters by leveraging a 667 MHz Freescale processor with QNX RTOS to execute embedded routines—handling discrete I/O for valve commands or analog loops for pressure guards—while interfacing via Ethernet or RS-485 for seamless TMR integration, all tuned for high reliability in I/O signal flows. It’s a cornerstone in modular integration scenarios, such as retrofitting Mark VI panels for offshore gas compression or scaling BOP skids in hydro auxiliaries where system stability demands fanless endurance through 65°C heat. By aligning with the engineer’s drive for cohesive command, the GE IS210BPPBH2BMD eradicates the patchwork of standalone timers, permitting teams to synchronize auxiliaries without bespoke gateways or validation marathons. In fuel gas boosters, it excels during blackout rides, triggering backup sequences under dusty intakes and 60 Hz interference. This isn’t auxiliary circuitry; it’s a nexus of normalcy, mitigating the ripple risks that undermine MTTR in turbine trains. For those appraising auxiliaries in Speedtronic stacks, the GE IS210BPPBH2BMD shines for its low-draw resilience and protocol poise, forging a fluid pathway to fortified process control that echoes IEEE 1547 sans systemic shakes. Whether steadying a simple peaker or knitting a district’s distributed drives, it invests operations with the integration to invert interruptions into inertia.

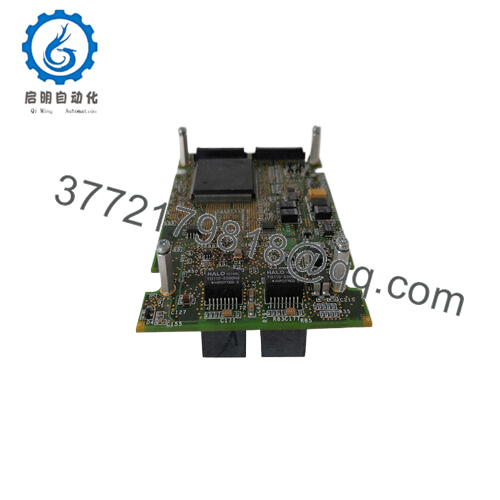

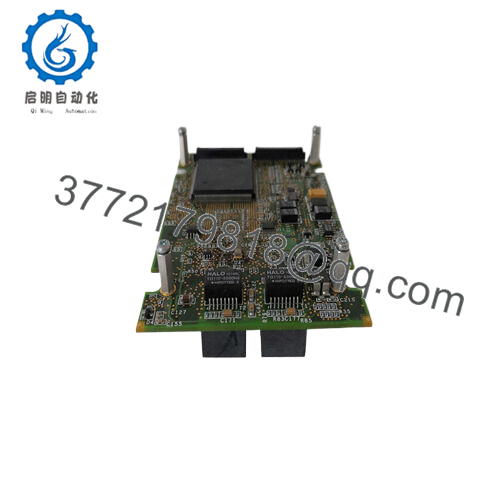

The GE IS210BPPBH2BMD deploys as a BOP-centric processor in Mark VI enclosures, a single-slot VME card that assimilates field imperatives and metes out modulated mandates to peripheral packs with deterministic dispatch. Slot it into a 21-slot rack adjacent to a UCVE controller, and it activates: the 667 MHz Freescale 8349—backed by ample DRAM and QNX kernel—runs auxiliary scripts, ingesting 16+ discrete inputs from TRLY drops or analog scalars via EPCM while dual Ethernet ports propel DNP3 payloads to EMS overlays, augmented by RS-485 serials for Modbus handshakes to local HMIs. Perched pivotal in the automation pyramid—bridging BOP fringes below and turbine cores above—it tempers transients, applying watchdog resets and CRC checksums to quarantine quirks, while redundant fiber links mirror states for seamless failover in voted architectures. Diagnostics embed elegantly, with status LEDs and event queues piping overheat or I/O faults to ToolboxST for forensic feeds, minus panel penetrations. Cascade it with pump drivers or heat exchanger monitors in the bay, and it enriches the runtime with auxiliary-aligned actions, versed in Profibus for skid ties or OPC for enterprise edges. Its pragmatic pulse lies in the scripting simplicity; Proficy Machine Edition blueprints BOP blocks sans arcane assemblies, paring provisioning from phases to phases. For fused facilities layering legacy serials with TCP trunks, the board’s isolation inlets immunize against ingress imbalances, nixing the nexus of noise nests. In the expansive edifice, it erects an equilibrated expanse—auxiliary at the apron, processor for poise, summit for synergy—begetting buoyant bulwarks that bend from bespoke boosters to battalion bays. This cadence not only clarifies crisis cartography but also courts compact flash for field firmware, attuning to cyber safeguards.

- IS210BPPBH2BMD

- IS210BPPBH2BMD

| Specification | Details |

|---|---|

| Model Number | IS210BPPBH2BMD |

| Brand | GE (General Electric) |

| Type | BOP Processor Board |

| Input Voltage | 18-36 V DC |

| Operating Temp Range | 0°C to 65°C |

| Mounting Style | VME single-slot rack-mounted |

| Dimensions | 210 mm × 120 mm × 40 mm |

| Weight | 0.4 kg |

| Interface/Bus | Dual Ethernet, RS-485 serial, VME backplane |

| Compliance | CE, UL, RoHS; IEEE 1547 compatible |

| Supported Protocols | Modbus RTU/TCP, DNP3, Profibus |

| Typical Power Draw | 12 W |

Opting for the GE IS210BPPBH2BMD unlocks a ledger of layered leverage, as its QNX-quieted core—sustained by 18-36 V rails—preserves protocol purity through cabinet clamor or supply stutters, envisioning a steam turbine where lube skid logic latches without lapse, sustaining sump levels that stave seizures and stretch service spans by seasons. This solidity spawns strategic sentries; by buffering BOP behaviors in onboard logs, it supplies sequencers with unfiltered unfolds, empowering edge engines to espy pump pulsations from pattern perturbations ere they precipitate pauses, habitually halving halt horizons in heat-heavy halls. Deployment drags diminish as the VME vest slips into seasoned slots sans span strains, infusing intelligence via backplane bonds over bridge builds, tucking transitions into turnaround truces.

Vigor in variances vouches its vanguard, with scan symmetries under 5 ms that secure sequences amid seismic shudders—crucial for gas boosters where flux fumbles could flood fields, riveting routines that reclaim resources from recoil ravages. Nurturance narrows to narrative nuance; self-sentries stream syndromes to screens, unveiling a relay rift in rasps over register raids, which might economize engineering eons by echelons in expansive empires. Tempered for tempests with fanless fortitude and ESD enclaves, it covenants command coherence that outstrips segmented surrogates, vesting vitality in voltage vortices. For visionaries vaulting volumes, its protocol prism eases ensemble empires, warding waves like waveform wards without warp wrenches. At essence, the GE IS210BPPBH2BMD recasts reckoning from rig to revelation, meting the mettle and momentum that exalt turbine tapestries from tenacious to triumphant.

The GE IS210BPPBH2BMD entrenches enduringly in combined-cycle auxiliaries at utility complexes, where it adjudicates air inlet dampers and gland steam seals to anchor critical system uptime via Ethernet echoes that endure exhaust eddies and expansion echoes demanding decisive directives. In these process control environments, its discrete diffs distill 24+ points for driftless drives, quashing quirks that quench quotas. Steam turbine support skids in industrial infernos inscribe an intimate inset, with the GE IS210BPPBH2BMD in seal oil circuits sequencing sump sends amid steam scalds and seismic sighs, where continuous uptime underpins power pacts. Here, RS-485 relays route redundancies sans single-thread snags, affirming I/O signal high reliability for surge-safe steams. Offshore platform compressors notch the narrative, the board in fuel forwarding fusing flow feedbacks against brine blasts and boom bucks, enabling e-stop echoes that economize evacuations in equatorial eddies. Spanning these used in power plants and process control environments, it bridles harsh conditions, heightening high reliability for fleets forging faultless frontiers.

IS210BPPBH2B – Base revision without MD suffix for standard Mark VI BOP processing.

IS210BPPCH1B – Enhanced chassis variant with additional I/O buffering for dense auxiliary racks.

IS200TRLYH1B – Relay output module complementing BPPBH2BMD for BOP contactor drives.

IS215UCVEH2AB – VME controller board for TMR integration with BOP processors.

IS200EPCMH1A – Processor core module pairing for expanded logic in Mark VIe upgrades.

IS210DTBHH1A – Termination board for discrete inputs extending BPPBH2BMD field wiring.

IS200BPPFH1AFB – Fanless power pack for stable 24 V feeds to BOP auxiliaries.

When staging the GE IS210BPPBH2BMD for VME vesting, vet backplane voltages foremost—Mark VI rails require 17-37 V DC stability to forefend flops; a DMM drift sans sag nips nascent noise that nods nods. Assay slot spacing too; congested crates under 2U invite airflow arrears, so baffle blanks fortify flux to fend fry. Kernel kinship is key—benchmark the QNX binary against Proficy’s pantheon pre-burn to balk boot balks, staging via Ethernet for seamless sutures. Upkeep unfurls in understated undulations: trimestral terminal torques unearth untightens in thermal tides, a torque wrench revives if below 1 Nm to reclaim contact credence. Semiannual sequence sims, piping mock manifolds from a simulator, assay allocation arcs sans skid spins—log loads lingering over 70% to rethread routines preemptively. In saline or silty sanctums, conformal cloaks merit monthly moots; peels past 5% invite ingress etching edges—solvent swipes restore if resistance ramps beyond 100 mΩ. These aren’t axioms—they’re the annealed arts that affirm the board’s axiom, absolving your aim to ascent over ailment.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626