Description

In the demanding landscape of turbine management and power generation, where seamless bridging between control processors and I/O modules is critical to prevent communication breakdowns or data silos—consider a gas turbine in a combined-cycle facility where a faulty bridge interface disrupts signal handoff during load ramps, leading to governor desync and efficiency drops, or a steam unit in a utility plant where isolated bus faults amid transients cascade into protective trips and unplanned outages—these disruptions highlight the need for reliable interconnects that maintain data flow without introducing latency or single points of failure. Such vulnerabilities plague legacy Speedtronic systems, where standard bridges overwhelm with wiring complexities or lack robust isolation, resulting in signal noise, integration hurdles, or diagnostic gaps that prolong recovery and escalate compliance costs in high-reliability process control environments. The GE IS210AEDBH4AGD tackles this as a bridge interface card from GE Vernova’s (formerly GE) Mark VI series, designed to facilitate high-speed data exchange between core controllers and peripheral modules, ensuring high-fidelity I/O signal routing and modular fault tolerance in turbine control architectures.

This card is vital in scenarios like retrofitting Mark V to VI for enhanced redundancy in heavy-duty turbines, where its conformal-coated design enables deployment in harsh enclosures without corrosion risks, or in industrial cogeneration where variable loads demand adaptive bus bridging to avert nuisance alarms. In a peaking gas turbine, for instance, it mediates signals from vibration sensors during rapid startups, delivering clean data paths to prevent overspeed without the yield losses from bridge-induced drops. For offshore platforms with vibration-laced cabinets, the GE IS210AEDBH4AGD supports 24 VDC operation with ±10% tolerance, upholding system stability across supply variances. It’s a staple for scalable integrations in multi-shaft setups, where its group variant 4 compatibility ties into VPRO processors, minimizing engineering overhead in EMI-dense or thermal-challenged zones.

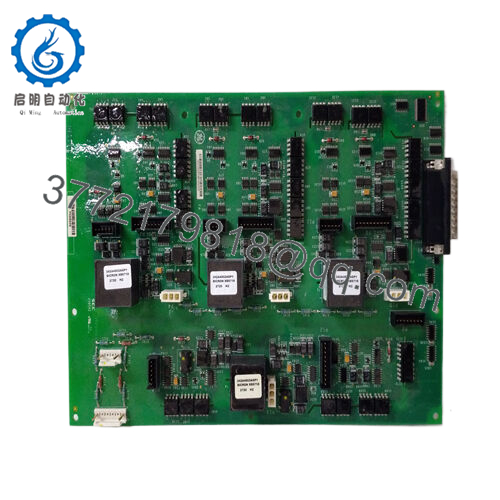

Engineered for the engineer’s toolkit, it features metal film resistors, capacitors, diodes, and transistors for precise signal conditioning, with nine drilled mounting points and slots for ICs/transformers to ensure vibration resistance. In arc-prone bays or grid-unstable sites, its isolation fortifies against transients, while front/back surface components enable compact layouts. For teams sustaining Mark VI fleets, the GE IS210AEDBH4AGD extends viability, reusing backplane standards to defer refreshes, repositioning bridges from fragility points to resilient conduits in industrial automation where data flow fuels every ramp.

When integrating the GE IS210AEDBH4AGD into your Mark VI ecosystem, picture it as the communicative nexus between core processors and I/O racks, where it routes signals via right-angled cable connectors (marked 574 9771-1 1301) and header pins, enabling up to 2.5 A current handling for peripheral handoffs in turbine cabinets. This card slots into standard Mark VI backplanes, perching at the interface layer—directly linking VPRO controllers to terminal boards but extending via serial bus for remote diagnostics in HMI oversight. In a stratified stack, it pairs with upstream <R> cores for algorithm bridging or downstream RTDB for termination, distributing data loads to circumvent single-link failures.

In daily flow, it arbitrates bus traffic at high speeds, conditioning analog/digital streams with integrated circuits for error-free exchange, while auxiliary headers support TMR configurations for sub-50 ms failover. Diagnostics come via onboard status indicators and bus hooks, flagging connector faults or overloads in ToolboxST for remote analysis—key in process control where off-site HMI trumps on-site dives. Without native power regulation, it draws from rack supplies (24 VDC), but its conformal coating enables IP54-like resilience in humid vaults, while firmware allows online parameter tweaks without de-energizing.

This adaptability reaches hybrid Mark VI nets: embed it in IP20 enclosures with shielded cables, populate slots via guided insertion for custom bridging, and test integrity with continuity checks to affirm against crosstalk. For backplane pros, the GE IS210AEDBH4AGD demystifies interfacing, turning core silos into bridged ensembles that scale with module counts, enhancing industrial automation from disjointed data to unified streams.

- IS210AEDBH4AGD

| Specification | Details |

|---|---|

| Model Number | IS210AEDBH4AGD |

| Brand | GE Vernova |

| Type | Bridge Interface Card (Mark VI Series) |

| Input Voltage | 24 VDC (±10%) |

| Operating Temp Range | -30°C to 70°C |

| Mounting Style | Backplane / Rack |

| Dimensions | Approx. 10.16 x 16.51 x 2.54 cm |

| Weight | 0.2 kg |

| Interface/Bus | Header Connectors, Right-Angled Cable |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Mark VI Internal Bus |

| Typical Power Draw | 2.5 A max |

Opting for the GE IS210AEDBH4AGD equips your turbine bridges with steadfast signal continuity that masters transient threats, its header-based routing—handling 2.5 A loads—facilitating handoffs in <20 ms to avert desyncs in ramp sequences where latency erodes stability and spawns trips. This endurance extends bus life by isolating noise with conformal coating, easing thermal strain on controllers and optimizing capex in multi-unit ops, all within a drilled/slot design that reuses Mark VI footprints without vent woes.

The integration payoff intensifies via Speedtronic lineage, where it repurposes cable layouts for add-ons like TMR interlocks, compressing tie-ins from shifts to setups and lightening opex in turbine arrays. Upkeep refines via connector-embedded status that logs faults for predictive pulls, shortening hunts from pin probes to console cues—empowering crews for bridging over breakdowns. Forged for bays laced with damp or dust, it clings to path integrity over 70°C cycles, forestalling replacements and attuning to MTTR vows in regulated ops.

The long arc spotlights efficiency amplifiers—compact 2.5 A draw trims rack thermals, while slot population defers custom cards for leaner setups that yield to bridge booms. In high-reliability pursuits, the GE IS210AEDBH4AGD tempers total risks, from galvanic guards that nix grounds to monitor chains that norm drifts for spares, etching a bridge web that braves barrages in turbine control.

In gas turbine peaking units, the GE IS210AEDBH4AGD bridges core-to-I/O during fast starts, routing signals amid flame roar to secure critical system uptime in process control environments where interface fidelity averts governor hunts. Its high-reliability headers process I/O signals from VPRO, ensuring ramp cohesion.

Steam turbine islands deploy it for protective bridging under load swings in boiler bays—yielding cable-tuned paths for continuous baseload where desyncs imperil blade paths. In aero-derivative drives for pipeline compression, it mediates surge data against torque flux in remote vaults, supporting modular TMR expansions. These roles exalt the GE IS210AEDBH4AGD as a bridge bastion in grueling, command-crucial industrial automation, where card cunning meets endurance.

IS210AEDBH4A – Predecessor variant for Mark VI without conformal coating for indoor use.

IS210AEDBH3B – Enhanced model with additional headers for denser bus integrations.

IS200RTDBH1A – Termination board companion for signal routing.

IS210VPRO-I1 – Processor core mate for core-to-bridge interfacing.

IS200EXAMG1A – Analog module add-on for hybrid conditioning.

Mark VI Bridge Kit – Cable and header toolset for custom configs.

IS210AEDBH4C – Updated revision for Mark VIe compatibility.

IS420AEDBH1A – Mark VIe equivalent with Ethernet extensions.

Before backplane-seating the GE IS210AEDBH4AGD, verify header pinouts against your Mark VI chassis—mismatches ghost paths, so continuity-check with a meter if splicing revisions. Scrutinize 24 VDC rails for <5% ripple, as hums distort bridges; decouple with ferrites if cores nearby buzz. Set any jumpers per diagram before power-up, dodging init faults.

In service, husbandry pares to tactical glances that suit sweeps. Monthly, eye status LEDs for bridge throbs—vibrant sequences endorse flow, but fades summon a bus dump to map anomalies. Quarterly, reseat cables for oxidation and cycle self-tests to gauge routing under load. For conformal-coated units, annual visual scans for delams precede full-load sims to vet thermal risers under 70°C. Per GE’s Mark VI codex, this liturgy limns the GE IS210AEDBH4AGD as a tacit overlord, harvesting equity with stingy pulls in your signal patrol.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626