Description

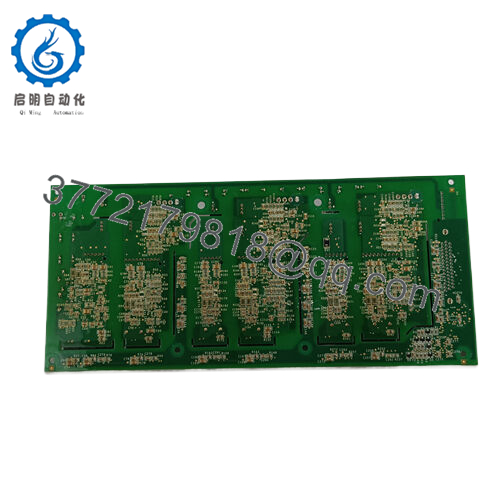

The GE IS210AEBIH1BED is a specialized AE (Analog Electronics) Bridge Interface Card designed for use in GE’s Mark VI and Mark VIe turbine control systems. This module is crucial for precise monitoring, control, and protection of turbomachinery, acting as an interface for analog signal conditioning and data acquisition from sensors used in turbine operation.

Key features of the GE IS210AEBIH1BED include:

- High performance with advanced processors and precise control algorithms for fast and accurate response.

- High reliability ensured by rugged design and quality components suitable for harsh industrial environments.

- Easy programming and integration with rich interfaces and development tools.

- High precision analog inputs and outputs to support accurate measurement and control.

- Compatibility with various sensors and actuators to build a complete turbine control system.

- GE IS210AEBIH1BED

Technical details:

- Dimensions: approximately 16 cm x 16 cm x 12 cm.

- Weight: about 0.8 kg.

- Operating temperature range: -40°C to +70°C.

- Supports analog voltage or current input signals configurable for specific application needs.

- Interfaces include two COM ports, a reset switch, and a 10BaseT Ethernet connector for network communication.

- Supports integration with large control systems providing turbine monitoring and safety functionalities.

| Parameter | Value |

|---|---|

| Model | GE IS210AEBIH1BED |

| Manufacturer | General Electric (GE) |

| Product Type | AE Bridge Interface Card |

| Dimensions | 16 cm x 16 cm x 12 cm |

| Weight | Approximately 0.8 kg |

| Operating Temperature | -40°C to +70°C |

| Input Signal Type | Analog voltage/current (configurable) |

| Communication Ports | 2 COM ports, 1 Ethernet 10BaseT |

| Application | Turbine control and monitoring |

The IS210AEBIH1BED is designed for easy integration within the Mark VI and Mark VIe turbine control platforms, providing precise and reliable analog signal processing essential for turbine operation and protection. Its robust construction ensures long-term operation under demanding industrial conditions.

Installation requires proper mounting within control racks compatible with Mark VI series, careful connection to sensors and actuators, and network integration via Ethernet and serial ports. Routine maintenance involves functional verification, firmware updates, and diagnostics facilitated by the module’s communication interfaces.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626