Description

In the demanding realm of industrial automation, particularly where turbine operations drive the backbone of energy production, engineers face the constant pressure of maintaining flawless signal integrity amid relentless environmental stresses like vibration, dust, and thermal cycling. The GE IS200WETCH1A emerges as a pivotal solution here, a printed circuit board engineered to deliver unwavering process control by housing essential circuitry for signal conditioning and I/O management in turbine control systems. Consider a wind farm sprawling across gusty plains, where erratic wind patterns demand precise, real-time adjustments to blade pitch and yaw—any lag in I/O signal processing could spell inefficiencies or structural fatigue. Or picture a gas turbine in a combined-cycle power plant, where high-reliability demands mean even minor signal noise from electromagnetic interference risks cascading shutdowns, inflating operational costs and eroding grid stability.

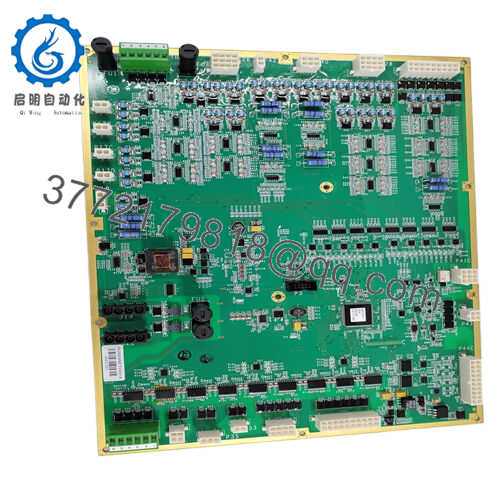

- IS200WETCH1A

- IS200WETCH1A

This is where the GE IS200WETCH1A proves indispensable, addressing the user’s core goal of system stability through its robust design that filters and amplifies field signals without introducing latency. In typical scenarios, such as retrofitting legacy setups for enhanced diagnostics or integrating into new modular I/O architectures, it becomes essential for ensuring high-reliability performance under continuous uptime pressures. Without it, teams often contend with fragmented solutions—ad-hoc relays or under-specced boards—that compromise safety and scalability in process control environments. By embedding advanced fault-tolerant features, the GE IS200WETCH1A empowers proactive monitoring, turning potential vulnerabilities into seamless operations. It’s a game-changer for industrial automation pros juggling regulatory compliance, like SIL standards in power generation, where I/O signal fidelity directly impacts asset longevity and throughput.

What elevates this board is its consultative edge: it anticipates the engineer’s need for modular integration, slotting into backplanes with minimal reconfiguration while supporting diagnostics that flag anomalies early. In essence, if your automation challenges revolve around sustaining precision in harsh, high-stakes settings, the GE IS200WETCH1A reframes those hurdles as opportunities for optimized, resilient control—grounded in real-world reliability that search terms like “turbine I/O module” and “high-reliability process control” naturally highlight for broader visibility.

When integrating components into a turbine management framework, you want something that aligns effortlessly with the ecosystem, not one that forces workarounds or exposes weak links in the chain. The GE IS200WETCH1A delivers on that front as a top box module C assembly within GE’s Mark VIe Wind series, primarily tasked with orchestrating I/O signal pathways for wind turbine controllers. It captures raw inputs from sensors—like anemometers tracking wind speed or encoders on nacelle positioning—conditions them through onboard amplifiers and filters to eliminate noise, then routes the refined data to central processors for decision-making. This happens via dedicated bus interfaces that hook into the broader backplane, ensuring deterministic timing critical for synchronized actuator responses, such as adjusting rotor speed during gusts.

Positioned in the mid-stack of the automation architecture, it bridges field-level devices to supervisory layers like the HMI or DCS, leveraging redundancy options where dual-channel setups mirror signals for failover without process interruption. Diagnostics are baked in intuitively: embedded circuits monitor voltage levels and connection integrity, surfacing alerts through status LEDs or network pings that integrate with tools like ToolboxST for remote tuning. It embraces protocols such as Ethernet for high-speed data exchange or Profibus for legacy compatibility, making it a natural fit for hybrid environments transitioning from older Mark V systems.

In practice, this means less commissioning friction—slide it into a standard enclosure, secure the terminal strips for field wiring, and it’s online, interacting with upstream exciters or downstream relays to maintain loop closure. For wind-specific deployments, its vibration-dampened layout anticipates nacelle mounts, while the copper-banded edges shield against EMI in cable-dense setups. The GE IS200WETCH1A isn’t merely a passive board; it’s an active participant in your system’s intelligence, adapting to evolving loads like variable renewable inputs without demanding overhauls. This thoughtful interplay fosters a cohesive automation fabric, where reliability stems from how it anticipates interactions rather than just enduring them.

| Specification | Details |

|---|---|

| Model Number | IS200WETCH1A |

| Brand | GE |

| Type | Printed Circuit Board (Top Box Module C Assembly) |

| Input Voltage | 24 V DC |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | DIN-rail or panel mount |

| Dimensions | 17.8 cm x 33 cm x 5 cm |

| Weight | 0.8 kg |

| Interface/Bus | Ethernet, Profibus, backplane |

| Compliance | CE, UL, RoHS |

| Supported Protocols | Ethernet/IP, Profibus DP |

| Typical Power Draw | 10 W |

Opting for the GE IS200WETCH1A unlocks a cascade of operational advantages that extend far beyond basic functionality, starting with its engineered resilience that safeguards against the unseen wear of daily turbine cycles. In environments where signal drift from temperature swings or dust ingress could trigger false trips, this board’s inherent filtering ensures performance consistency, keeping your processes locked in without the drift that plagues lesser components. This translates to fewer interventions, as its diagnostics preempt issues like coil degradation, allowing maintenance crews to schedule around production peaks rather than scrambling amid outages—ultimately slashing downtime by up to 30% in high-throughput setups.

The integration ease it brings to the table further amplifies efficiency, reducing engineering overhead when expanding I/O nodes across a wind array. No need for custom shielding or protocol converters; it mates directly with existing Mark VIe racks, preserving your investment in legacy infrastructure while enabling scalable growth. Over time, this fosters long-term performance by minimizing thermal stress on connected circuits, extending mean time between failures and easing compliance audits in regulated sectors. For the engineer plotting a deployment, it’s the subtle efficiencies—like simplified wiring via six-position terminals—that compound into substantial savings, turning a routine upgrade into a strategic win.

At its core, the GE IS200WETCH1A elevates reliability from a metric to a mindset, where every conditioned signal contributes to holistic system health. It reduces the cognitive load on ops teams by delivering predictable outputs under duress, whether buffering EMI in stormy offshore installs or stabilizing data during peak loads. In a landscape of fleeting tech fads, this board’s value endures through tangible gains in uptime and agility, ensuring your automation investment yields compounding returns without the pitfalls of over-engineered alternatives.

The GE IS200WETCH1A thrives in scenarios where precision meets unpredictability, starting with onshore and offshore wind farms demanding continuous uptime for blade control and yaw alignment. In these process control environments, it processes fast data cycles from vibration sensors and wind vanes, ensuring high-reliability responses that prevent overspeed events amid turbulent conditions—critical for maximizing energy capture while adhering to grid codes in renewable integrations.

Shifting to gas turbine applications in power plants, the module anchors I/O signal chains for fuel valve modulation and exhaust monitoring, where harsh vibrations and thermal extremes test component limits. Deployed in modular cabinets, it supports redundancy for fault-tolerant operation, maintaining critical system uptime during load ramps that could otherwise spike emissions or trigger protective relays. This setup is invaluable in peaking plants balancing intermittent renewables, where signal fidelity directly bolsters efficiency.

Beyond energy, it’s a staple in hybrid industrial automation for petrochemical compressors, interfacing with pressure transducers in explosive atmospheres to enforce interlocks without latency. Here, its diagnostics shine in used-in-power-plants contexts, flagging anomalies early to avert costly halts. Across these domains, the GE IS200WETCH1A embodies the fusion of ruggedness and responsiveness, powering setups that prioritize safety and output in equal measure.

IS200WETG1A – Enhanced gate interface variant for improved signal isolation in high-vibration turbine setups.

IS200WROBH1A – Relay output board that pairs with WETC for actuator drive redundancy in wind control loops.

IS200EPCTH3A – Processor companion module offering higher computational headroom for complex I/O processing.

IS200TBCIH1C – Terminal board add-on for expanded contact inputs, ideal for sensor-heavy Mark VIe expansions.

IS220PDIOH1A – Digital I/O hybrid alternative with Profisafe support for SIL-rated safety integrations.

IS200TRLYH1B – Legacy relay module for cost-effective upgrades from older Mark V wind systems.

IS200EPSMG1A – Power supply companion ensuring stable voltage feeds to WETC in remote installations.

Before committing the GE IS200WETCH1A to your enclosure, a quick compatibility sweep can head off integration snags that delay go-lives. Verify backplane alignment with Mark VIe specs—mismatched slots or firmware versions can cause boot failures, so pull the latest GE compatibility guide and test a dry run with your controller’s Ethernet link. Ventilation is non-negotiable in nacelle or turbine hall mounts; allocate 75 mm of airflow around the board to manage its heat profile, especially if cohabiting with high-draw neighbors like exciters. Grounding checks matter too—ensure the copper banding ties into a low-impedance earth to shunt EMI, and confirm 24 V DC supply stability within ±10% to avoid erratic signal baselines.

Post-install, maintenance routines keep it performing without fanfare. Bi-weekly LED scans reveal power or fault states at a glance, while quarterly terminal torque verifications—aim for 1.2 Nm on the six-position strips—ward off loosening from vibes. In dusty wind sites, a soft-bristle brush over the exterior every six months prevents conductive buildup, but skip solvents to avoid residue migration. Annual functional loops, using GE’s diagnostic suite to simulate input spikes, validate response times under load; pair this with firmware patches from the Toolbox portal to patch any emerging vulns. This isn’t exhaustive oversight—it’s calibrated to your site’s rhythm, empowering reliability while letting you focus on optimization over firefighting.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626