Description

In the turbulent domain of wind turbine automation, where sensors battle relentless environmental stressors—gusting winds, corrosive salt spray, and extreme temperature swings—engineers face the critical challenge of maintaining precise, reliable data flow to prevent blade pitch errors or yaw misalignments that could lead to structural fatigue or costly grid disconnects. A single dropped signal can escalate into a turbine trip, slashing energy yields and triggering maintenance costs that erode slim margins in renewable operations. The GE IS200WETBHIB, a rugged top box terminal board from GE’s Mark VIe wind control suite, directly addresses this need by ensuring robust I/O signal integrity in the harshest conditions. Designed for industrial automation in wind farms, it delivers high reliability by conditioning and routing sensor data, enabling precise control over turbine dynamics in real-time.

Picture an offshore wind farm enduring North Atlantic squalls or an inland array grappling with dust storms in arid plains—settings where moisture, vibration, or EMI can degrade standard terminals, compromising process control. The GE IS200WETBHIB thrives here, its sealed, conformal-coated design safeguarding inputs from anemometers, strain gauges, or hydraulic sensors against ingress and noise, ensuring clean delivery to the Mark VIe controller. With support for modular integration, it simplifies retrofits in aging nacelles, aligning with IEC 61400 standards for wind turbine durability while reducing engineering overhead. By maintaining signal fidelity, it prevents false actuations that could stall operations, supporting continuous uptime and compliance with grid codes. For teams optimizing wind assets, the GE IS200WETBHIB empowers a focus on maximizing annual energy production, transforming raw environmental data into the steady pulse that drives efficient, sustainable power generation.

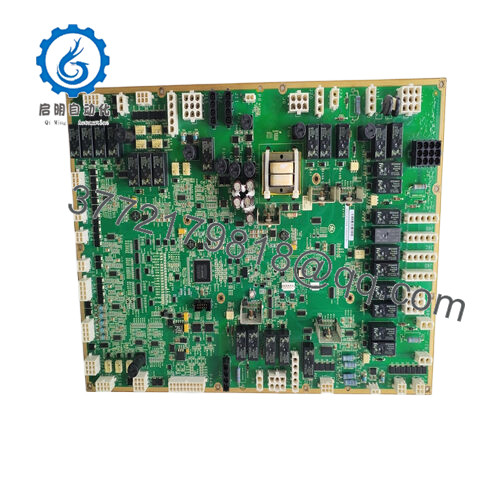

The GE IS200WETBHIB functions as a top box B terminal board in the Mark VIe ecosystem, acting as the nacelle’s signal gateway by aggregating and conditioning I/O from field sensors before relaying them to the main controller via Ethernet SRTP or Modbus TCP. Mounted in the turbine’s hub or top box enclosure, it processes up to 32 channels—mixing analog (4-20 mA, thermocouples) and digital (24 V wet/dry contacts)—using optical isolation to shield against EMI and ground faults common in wind setups. Signals from blade load sensors or yaw encoders pass through its screw terminals, get filtered for noise, and are multiplexed over shielded cables to the UCV controller, achieving sub-10 ms latency for responsive pitch or brake commands.

Positioned at the field interface layer, it integrates with auxiliary boards like the WETAH for expanded analogs or TREAH for trip outputs, supporting dual-path redundancy in critical loops to mimic TMR resilience without added hardware. Diagnostics flow through front-panel LEDs and ToolboxST queries, flagging channel drifts or seal breaches, while its IP66-rated enclosure and MIL-spec coatings endure 5g vibrations and 95% humidity, ideal for offshore rigs. The GE IS200WETBHIB streamlines wiring with pre-indexed terminal strips, cutting field setup time, and its Ethernet backbone supports DNP3 for grid telemetry, ensuring seamless SCADA integration. By anchoring the I/O periphery, it enables precise control sequences—like dynamic feathering or icing mitigation—while freeing engineers to refine turbine algorithms rather than wrestle with signal noise in wind-swept conditions.

- IS200WETBHIB

- IS200WETBHIB

| Specification | Details |

|---|---|

| Model Number | IS200WETBHIB |

| Brand | GE |

| Type | Top Box B Terminal Board (Wind I/O Interface) |

| Input Voltage | 18-32 V DC |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | Enclosure-mounted (nacelle/hub) |

| Dimensions | 250 x 150 x 60 mm |

| Weight | 1.1 kg |

| Interface/Bus | Ethernet SRTP, RS-485, screw terminals |

| Compliance | IEC 61400, UL 508, CE |

| Supported Protocols | Modbus TCP, DNP3, SRTP |

| Typical Power Draw | 10 W |

Choosing the GE IS200WETBHIB fortifies wind turbines with a resilience that withstands nature’s toughest assaults, ensuring that sensor signals remain pristine to drive precise pitch and yaw adjustments, boosting turbine availability and averting blade stress that could cost millions in repairs. Engineered for the punishing conditions of wind farms, its robust isolation and environmental sealing deliver long-term performance, enabling turbines to maintain peak output even during storm cycles, which directly enhances energy yields and grid reliability.

Maintenance becomes less burdensome, as the board’s diagnostic LEDs and remote polling capabilities pinpoint issues like signal drift or connector corrosion swiftly, reducing nacelle climbs and freeing technicians for predictive tasks like load trend analysis. Its plug-and-play compatibility with Mark VIe systems minimizes integration hurdles, accelerating commissioning in tight retrofit schedules and cutting capital dwell time. The GE IS200WETBHIB also enhances safety by isolating high-voltage transients, reducing arc risks during inspections. By embedding such dependability, it supports advanced control strategies—think real-time wake steering or curtailment optimization—while ensuring compliance with stringent grid codes, ultimately driving higher returns on wind investments through sustained, efficient operation.

The GE IS200WETBHIB is deployed in offshore wind turbines, where it channels accelerometer and hydraulic signals to prevent pitch overloads during 60 mph gales, ensuring critical system uptime in process control environments battered by corrosive seas and high vibrations.

Onshore wind farms in arid regions rely on the GE IS200WETBHIB to process anemometer and temperature inputs, combating dust ingress to maintain high reliability in continuous uptime scenarios, preventing yaw errors that could disrupt array synchronization.

Floating wind platforms leverage the GE IS200WETBHIB for inclinometer and pressure sensor I/O, enduring wave-induced oscillations to support fast data cycles, reinforcing industrial automation where precise tilt control ensures stability in turbulent waters.

IS200WETAH1A – Top Box A board for primary analog inputs in hub-focused wind applications.

IS200WETCH1A – Thermocouple-specific terminal for thermal monitoring alongside WETBHIB.

IS215UCVEH2A – Core controller processing WETBHIB’s I/O for wind sequencing logic.

IS200RAPAG1B – Power supply board delivering stable 24 V to WETBHIB’s field circuits.

IS200TREAH1A – Trip relay board amplifying WETBHIB outputs for emergency stops.

IS200TDBTH6A – Discrete I/O extender for additional binary channels with WETBHIB.

IS200VPROH2B – Protection module using WETBHIB inputs for overspeed safeguards.

IS200SRTDH2A – Startup interface for feathering sequences tied to WETBHIB data.

Before installing the GE IS200WETBHIB, verify nacelle grounding meets <1 Ω to prevent EMI bleed, and match terminal assignments to the SRTP map, as mispins can offset 4-20 mA loops by 5% or more—use a loop calibrator to confirm. Torque screw terminals to 8 in-lbs, using 12-14 AWG shielded cables, and ensure the enclosure’s IP66 gasket is intact, testing with a water jet if coastal exposure looms. Pre-stage the board at 0°C to avoid condensation on coatings, and validate Ethernet continuity with a 100BaseT tester to ensure <1 ms pings.

Ongoing maintenance involves quarterly inspections of terminal corrosion, especially in saline environments, using a borescope to check sealant integrity, and annual analog sweeps with a signal generator to verify ±0.3% linearity across channels. In dust-heavy sites, clean connectors with ESD-safe brushes every six months, and monitor LED status for flicker indicating loose pins. Firmware updates, if tied to controller patches, should occur during scheduled downtimes, with configurations backed up to SD cards. These practices, logged in your maintenance system, keep the GE IS200WETBHIB a reliable conduit, ensuring turbine signals remain sharp amidst environmental chaos.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626