Description

The GE IS200WEMAH1AEA circuit board is widely used in industrial automation and energy control sectors, especially in applications involving the GE Mark VI and Mark VIe turbine control systems. It plays a critical role in connecting, terminating, and distributing analog, digital, and communication signals between the control system and peripheral devices such as sensors and actuators. This makes it essential in industries like power generation, manufacturing, oil and gas, and process control, where precise and stable signal handling is key to maintaining continuous and efficient operation. For example, in gas, steam, or hydro turbine power plants, the IS200WEMAH1AEA reliably transmits turbine operational data—such as speed, temperature, and pressure—to control units that adjust and optimize performance. Its robustness enables it to function flawlessly even in harsh conditions characterized by high electromagnetic interference, temperature extremes, and mechanical stress, making it a trusted component for sustaining critical industrial processes.

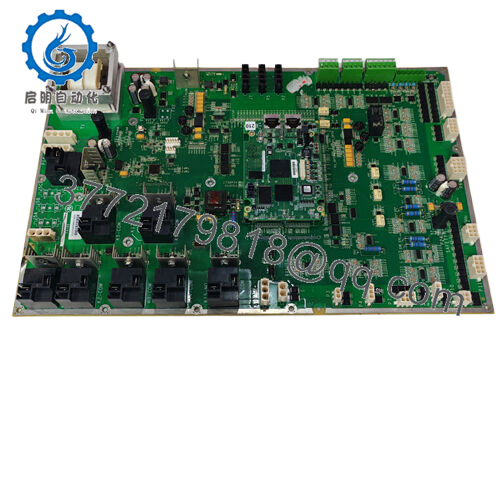

The GE IS200WEMAH1AEA is a printed circuit board designed to be integrated within the GE Mark VI and Mark VIe control systems. As a multi-channel terminal interface board, it facilitates seamless communication between the central control module and multiple input/output signal channels, serving as an interface hub for a broad range of sensors and actuators. This integration ensures accurate data transmission and system responsiveness. The board fits into racks or panels within control cabinets and supports hot-swapping, allowing replacement or maintenance without halting the entire system—an invaluable feature for minimizing downtime in continuous operation setups. Its modular and compact design ensures compatibility with other GE control modules, making it a scalable solution. For system integrators and engineers, the IS200WEMAH1AEA delivers a stable, flexible foundation for complex automation and control requirements.

- IS200WEMAH1AEA

- IS200WEMAH1AEA

From a technical perspective, the GE IS200WEMAH1AEA excels in high reliability and operational stability under rugged industrial environments. It supports a broad operating temperature range from -30°C to 70°C, with high immunity to electromagnetic interference to maintain signal integrity. The board handles multiple analog and digital signal channels simultaneously, ensuring comprehensive signal management in demanding automation setups. Constructed with industrial-grade materials, it withstands mechanical vibrations and environmental stresses typical in power plants and manufacturing plants. Its diagnostic capabilities provide real-time status monitoring and alarm support to detect faults swiftly, enhancing system reliability. Its rack or panel mount design facilitates organized installation within control cabinets, simplifying integration and maintenance workflows. The hot-swappable design further adds to longevity by enabling service without process interruption, which is critical for production continuity.

| Parameter | Value |

|---|---|

| Model | IS200WEMAH1AEA |

| Manufacturer | GE |

| Product Type | Printed Circuit Board |

| Signal Types | Analog, Digital, Communication Signals |

| Compatibility | GE Mark VI, Mark VIe Control Systems |

| Operating Temperature Range | -30°C to 70°C |

| Electromagnetic Compatibility | Industrial Standard Compliance, High Immunity |

| Mounting Method | Rack mount or panel mount |

| Diagnostic Feature | Real-time status detection and alarm support |

| Input/Output Channels | Multiple channels |

| Physical Dimensions | Not specified |

| Weight | Not specified |

The IS200WEMAH1AEA works seamlessly alongside related GE modules to create robust control systems. These include IS200WETCH1A, a related module with possibly complementary signal functions; IS200EMIOH1A, specialized in thermocouple signals used with the IS200WEMAH1AEA in combined systems; IS200VCMIH2BEE, a master communication controller managing high-level data transmission; IS200AEADH1ABA, focusing on specific power or signal processing roles; and IS200EROCH1ABB, tailored for certain industrial process controls that complement the general-purpose signal handling of the IS200WEMAH1AEA.

Installation requires a clean, ventilated environment with power off for safety. Proper wiring according to GE manuals is critical to ensure signal integrity and avoid faults. The board must be free from dust and regularly inspected for physical wear, connector stability, and temperature conditions. Monitoring diagnostic indicators aids in early fault detection. Periodic cleaning and adherence to maintenance protocols optimize performance and prevent operational disruptions.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626