Description

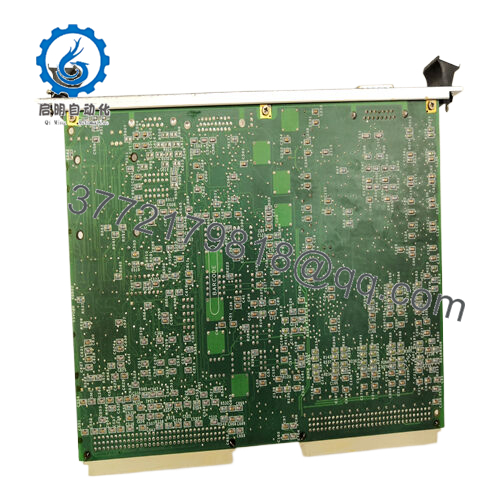

Product Model: GE IS200VSVOH1BDC

Product Brand: General Electric (GE)

Product Series: Mark VI IS200 Series

Product Features:

- Servo control card for 2- or 3-coil servo valve applications.

- Compatible with both active and passive speed sensors.

- Pulse-rate feedback input range: 2 Hz – 14 kHz.

- Rugged conformal-coated design for high-reliability turbine environments.

- IS200VSVOH1BDC

Applications & Industry Context

The GE IS200VSVOH1BDC module sits at the heart of many Mark VI turbine control systems, where precision control of servo valves determines the stability, responsiveness, and safety of critical power generation processes. It’s a specialized servo-valve control card designed for gas and steam turbines, often installed in energy plants, petrochemical facilities, and process industries that rely on electro-hydraulic actuation.

In practical operation, this board translates electronic control commands into exact physical valve positions. Whether modulating fuel flow, steam admission, or hydraulic pressure, the servo loop it manages must perform with micro-second accuracy. Turbine systems—especially those controlling steam bypass valves, inlet guide vanes, or nozzle actuators—demand stable proportional control even under heavy thermal and vibrational stress.

Field engineers often describe the IS200VSVOH1BDC as “one of those unsung heroes in the cabinet.” It’s rarely noticed when working correctly, yet indispensable when something goes wrong. When a servo valve sticks or feedback signals become erratic, this board is the key diagnostic checkpoint.

In many older GE turbine retrofits, engineers retain the GE IS200VSVOH1BDC because of its compatibility and proven track record. Its ability to handle both active and passive sensors simplifies integration with mixed-generation systems. Whether operating a Mark VIe upgrade or a legacy Mark VI VME rack, it provides a seamless bridge between control logic and high-power electro-hydraulic actuation.

Beyond turbines, the board finds niche use in industrial drive systems, test benches, and hydroelectric gate actuators—anywhere a reliable servo feedback and control interface is required.

Technical Features & Benefits

One of the hallmarks of the GE IS200VSVOH1BDC is its precision in controlling multi-coil servo valves. It supports both 2-coil and 3-coil configurations, the latter used in Triple Modular Redundant (TMR) systems for high-availability turbine applications. This makes it suitable for mission-critical loops where downtime is simply unacceptable.

Another strong feature is its sensor flexibility. It can work with active (powered) and passive (magnetic pickup) speed sensors. This dual compatibility allows integration with diverse sensor types—important when retrofitting or maintaining equipment across generations.

Its pulse-rate input capability (2 Hz to 14 kHz) enables it to interpret signals from flow dividers or other high-frequency feedback devices. This gives plant engineers flexibility to fine-tune the feedback loop resolution, ensuring precise actuator movement and tighter process control.

Durability is a key factor. The board uses conformal coating to protect sensitive components from humidity, oil mist, and airborne contaminants. In high-temperature turbine enclosures or compressor halls, this coating prevents moisture ingress and corrosion on copper traces—an often overlooked but critical design choice for long life.

Diagnostic indicators on the front panel—typically RUN, FAIL, and STATUS LEDs—provide immediate visual feedback for troubleshooting. During commissioning or maintenance, engineers can quickly identify a healthy module, a failed loop, or communication issues without connecting external tools.

Electrical isolation and signal conditioning on this module are engineered for stability. Noise from heavy-current equipment—motors, solenoids, or variable-speed drives—can induce signal jitter, but the IS200VSVOH1BDC filters and regulates its feedback channels to maintain clean loop control.

Finally, its VME form factor and pin-compatible design make it a drop-in replacement for older VSVOH1B or VSVOH1A boards. This backward compatibility minimizes downtime during upgrades or repairs.

Benefits summary

- Precision – stable servo response across wide temperature and load ranges.

- Reliability – conformal coating and robust PCB design ensure long-term service.

- Flexibility – compatible with varied sensor and coil configurations.

- Ease of integration – designed for seamless operation in GE Mark VI control racks.

- Serviceability – diagnostic LEDs and modular rack interface reduce troubleshooting time.

Technical Specifications Table

| Specification | Description |

|---|---|

| Model | GE IS200VSVOH1BDC |

| Product Type | Servo Valve Control Card |

| Manufacturer | General Electric (GE) |

| Product Series | Mark VI IS200 Series |

| Servo Configuration | Supports 2-coil or 3-coil servo valves |

| Sensor Compatibility | Active or passive speed sensors |

| Pulse Feedback Range | 2 Hz – 14 kHz |

| Mounting Type | VME Rack, IS200-family backplane |

| Front Indicators | RUN / FAIL / STATUS LEDs |

| PCB Protection | Conformal coating for humidity and dust resistance |

| Operating Environment | 0 °C – 60 °C (typical) |

| Application Area | Steam and gas turbine control systems |

| Typical System | GE Mark VI or compatible VME-based racks |

Product Role & System Fit

In a Mark VI control system, the GE IS200VSVOH1BDC functions as the dedicated servo driver for valve actuation loops. Each VSVO card interfaces with corresponding TSVO terminal boards, routing signals to and from the servo valves.

Think of it as the nerve-to-muscle link in the turbine’s control “nervous system.” The Mark VI controller (usually via the SPEEDTRONIC logic) computes desired actuator positions based on load demand, temperature, or pressure. Those commands travel over the VME backplane to the IS200VSVOH1BDC, which converts them into precise analog drive currents for the servo coils.

The module then reads back feedback signals—either analog LVDTs or high-frequency pulse sensors—to verify the actuator position. This closed-loop process repeats thousands of times per second, ensuring turbine components move exactly as intended.

Its ability to support Triple Modular Redundant (TMR) configurations enhances fault tolerance. Each of the three servo coils receives signals from independent control channels. If one fails, the system continues operating safely, a crucial feature in power-plant applications.

Integration is straightforward because the IS200VSVOH1BDC adheres to the IS200 family’s standardized connectors and mechanical format. It shares the same VME backplane pinout, simplifying installation for technicians familiar with GE control hardware.

The board’s firmware executes servo loop algorithms directly on the card. This local processing reduces the computational burden on the main controller, improving response times and ensuring smoother valve movements—especially beneficial in fast-acting gas turbines.

Installation & Maintenance Insights

Although the GE IS200VSVOH1BDC is robust, its longevity depends on proper handling and installation practices. Below are practical, field-tested recommendations:

- Rack Preparation – Always power down the Mark VI VME rack before inserting or removing the module. Inspect the slot for dust or corrosion on the backplane connectors.

- Insertion Technique – Align the module carefully with the guide rails and seat it firmly into the backplane connector. Use the captive screws on the front panel to secure it—loose connections can cause intermittent signal faults.

- Wiring Practices – When connecting servo valves, ensure correct polarity on each coil terminal. Use shielded twisted pairs for feedback lines to minimize noise, especially for long cable runs.

- Sensor Verification – Configure the board for the appropriate sensor type. Using a passive sensor in an active input channel may produce unstable readings.

- Initial Commissioning – Observe front-panel LEDs after power-up. A steady green “RUN” indicates successful initialization. A red “FAIL” usually points to wiring issues, sensor faults, or coil overload.

- Environmental Conditions – Although conformal coating provides protection, avoid mounting near heat sources or oil mist exhausts. Ensure airflow in the cabinet is unobstructed.

- Routine Maintenance – Periodically check for dust accumulation on the board edge and connectors. A soft, anti-static brush or dry air can be used for cleaning.

- Spare Management – Always keep at least one tested spare IS200VSVOH1BDC module in inventory. Label its firmware revision clearly, as Mark VI systems sometimes require matching revisions for redundancy.

Seasoned turbine engineers emphasize one rule: if a servo loop behaves erratically, check wiring first, board second. In most cases, mis-termination or sensor degradation—not the board—is the culprit.

Related Models

If you’re working within the GE Mark VI IS200 family, these related models may also interest you:

- GE IS200VSVOH1B – Previous generation VSVO card, similar function, different hardware revision.

- GE IS200TSVOH1B – Terminal board companion for VSVO control cards, handling servo wiring and signal routing.

- GE IS200TSVOH1C – Variant terminal board for alternate servo configurations.

- GE IS200VSVOH1A – Earlier VSVO revision with limited pulse-rate input range.

- GE IS200VSVOH1BED – Enhanced diagnostic features and component updates.

- GE IS200TBTCH1CBB – I/O terminal card complementing servo boards for turbine systems.

- GE IS200TSVCH1B – Control card variant for small or single-coil servo setups.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626