Description

Real-World Use & Application Scenarios (Open Strong)

Where is this product used and why? In heavy industries that rely on precise motion and rapid response, devices like the GE IS200VSVOH1B act as the critical link between sensing, control, and valve actuation. They’re deployed in power generation environments, turbine control suites, and complex plant automation where deterministic timing and robust fault handling are non-negotiable. Operators use these boards to drive electro-hydraulic servo valves, manage position feedback via LVDT sensors, and support high-integrity servo loops within Mark VI-based control architectures. In oil and gas facilities, combined heat and power plants, and large-scale industrial plants, engineers count on this module to deliver consistent servo performance, noise-tolerant signal conditioning, and reliable integration with a range of fieldbuses and deterministic networks. The IS200VSVOH1B is designed to withstand mission-critical environments—vibration, temperature extremes, and EMI—while enabling precise control of hydraulic actuators and synchronized valve operations. In practice, technicians rely on this board to ensure smooth operation of turbine controls, refine closed-loop performance, and enable rapid diagnostics across redundant or simplex configurations. The full model name GE IS200VSVOH1B appears in bold to emphasize its identity in procurement catalogs and maintenance manuals, while search phrases like used in industrial automation and applicable in control systems help buyers locate it efficiently.

Product Introduction & Positioning

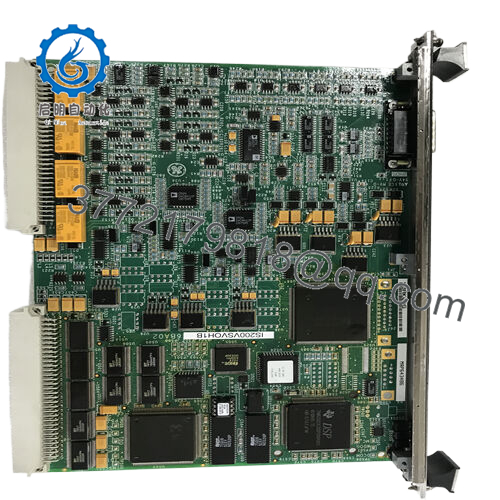

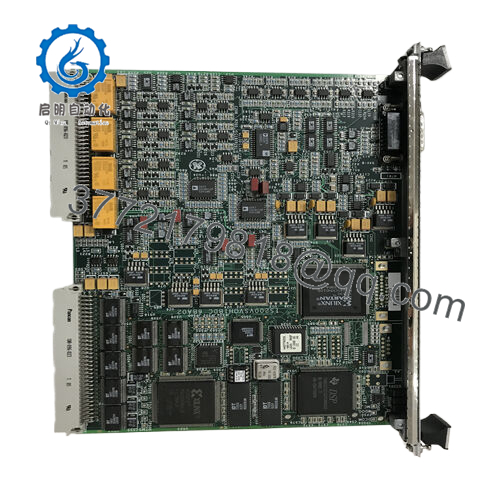

GE IS200VSVOH1B is a VME-based servo control board that serves as a dedicated servo drive interface within GE’s Mark VI control lineage. It functions as a servo control module that translates digital commands into precise motion for four electro-hydraulic servo valves, with LVDT-based feedback supporting accurate position sensing. Positioned within turbine control panels and motor-control architectures, this board acts as a bridge between high-level control logic and field actuators, enabling deterministic servo performance in both redundant and simplex configurations. Its value lies in tight integration with the Mark VI ecosystem, reliable real-time response, and the ability to expand servo capability without overhauling the control topology. By aligning with the broader turbine control stack and compatible interfaces, the GE IS200VSVOH1B provides engineers with a familiar, proven solution that minimizes integration risk while delivering predictable, long-term performance.

Key Technical Features & Functional Benefits

The GE IS200VSVOH1B delivers robust servo control with deterministic timing and precise valve actuation. Its core strengths include fast, cycle-accurate response for servo loops, and reliable LVDT excitation and feedback handling that preserve high-resolution position data. The hardware design emphasizes ruggedization to withstand industrial environments, with a layout optimized for VME backplanes and tight cabling in turret panels. Compatibility is a central theme, featuring support for GE’s Mark VI servo architecture and seamless interaction with standard turbine control networks and diagnostics. Long-term reliability is supported by proven thermal management and vibration tolerance, ensuring stable operation through maintenance cycles and plant duty cycles. Throughout, the model name GE IS200VSVOH1B is highlighted to reinforce product identity across engineering documents and maintenance records, helping buyers verify compatibility with existing Mark VI installations.

- IS200VSVOH1B

- IS200VSVOH1B

Detailed Technical Specifications

Model | IS200VSVOH1B

Brand | General Electric

Type | VME Servo Control Board

Mounting | VME chassis backplane

Related Modules or Compatible Units

GE IS200VSVOH1B — Same family within the Mark VI servo control ecosystem, designed for quartet-valve servo applications.

GE IS200VSVOH1BDC — Variant with extended diagnostic features for enhanced upkeep.

GE IS200SCDV0H1B — Higher-density I/O option for larger control schemes.

GE IS200VSVOL1B — Alternative voltage/current rating for different actuator types.

GE IS200VTURB1B — Turbine-focused family member offering broader network compatibility.

GE IS200VSLV1B — Lower-profile form factor for compact panels.

GE IS200VSSV1B — Variant with enhanced protective coatings for damp environments.

Installation Notes & Maintenance Best Practices

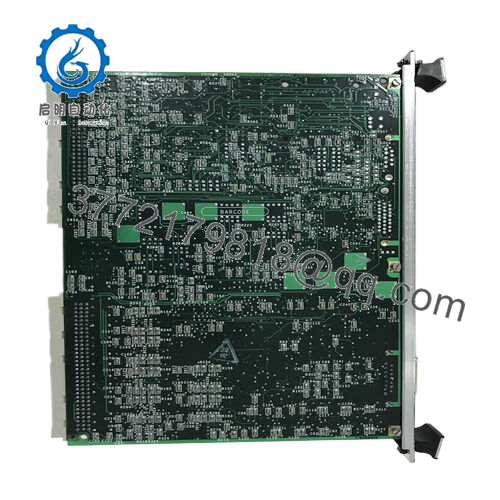

Before installation, verify cabinet dimensions to ensure proper clearance for heat dissipation and cable routing, and confirm that the mounting panel and backplane are compatible with the IS200VSVOH1B’s mechanical envelope. Grounding and surge protection should align with the plant’s electrical protection scheme, and a clear topology diagram should map the servo channels to the Mark VI controller and to the corresponding actuators. For maintenance, implement a quarterly inspection cycle focusing on connector integrity, vibration-induced wear, and the physical condition of the conformal coating or enclosure seals when applicable. Run routine signal integrity checks and verify LVDT excitation and feedback loops during commissioning, and maintain a firmware and software-change log with rollback procedures. Track environmental conditions and temperature margins to prevent thermal excursions from triggering drift in servo performance, and establish a health-monitoring dashboard to alert on abnormal servo counts or communication retries.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626