Description

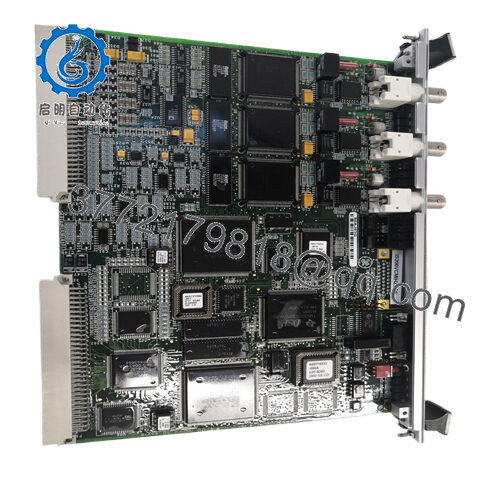

Product Model: GE IS200VCMIH2BEE

Product Brand: GE Automation / GE Fanuc

Product Series: Series 90-30 PLC Modules

Product Features:

- High-speed, reliable I/O performance for industrial environments

- Seamless integration with Series 90-30 PLC systems

- Compact form factor for space-efficient installations

- Robust design ensures long-term durability under harsh conditions

- IS200VCMIH2BEE

- IS200VCMIH2BEE

Applications & Industry Context

In industrial automation, the need for reliable input/output modules is critical, especially in sectors where downtime is costly. The GE IS200VCMIH2BEE is commonly deployed in manufacturing plants, energy facilities, and process automation environments. From conveyor control in automotive assembly lines to monitoring valves in chemical processing, this module ensures precise signal handling. Field engineers often remark on its resilience; even in dusty, high-vibration plants, the unit maintains stable communication between sensors, actuators, and the PLC core.

Food and beverage facilities also benefit from the GE IS200VCMIH2BEE because of its compatibility with hygienic setups. Its compact design allows for tight panel integration, and its fast response time ensures accurate product handling and quality checks. Even in water treatment plants, where conditions can fluctuate rapidly, the module provides consistent performance, helping operators maintain regulatory compliance with minimal manual intervention.

By focusing on adaptability, this module fits environments that demand both precision and reliability. Its ability to handle varied voltage inputs without degradation is particularly valued in power distribution and heavy machinery operations. Engineers frequently note that its predictable behavior reduces troubleshooting time and minimizes unexpected process interruptions, which is crucial in industries where uptime directly correlates with profitability.

Technical Features & Benefits

The GE IS200VCMIH2BEE is designed with engineers in mind, balancing performance, reliability, and ease of integration. Its high-speed processing ensures real-time signal handling, which is essential in automated control loops. It supports a broad range of digital input and output configurations, allowing flexible application across diverse systems.

Durability is another standout feature. The module’s robust PCB and industrial-grade components protect it against voltage spikes, electrical noise, and ambient temperature fluctuations. Many automation technicians appreciate the sturdy connectors and secure mounting options, which reduce installation errors and improve long-term stability.

In terms of system compatibility, the GE IS200VCMIH2BEE integrates effortlessly with Series 90-30 PLCs. Its firmware supports backward compatibility with legacy controllers, which is particularly advantageous in plants upgrading incrementally. Engineers often comment that the module’s diagnostic LEDs and clear labeling simplify troubleshooting—reducing maintenance time and operational risk.

Additionally, the module’s compact design allows it to fit into panels where space is limited, without sacrificing I/O capacity. This enables engineers to design more efficient control cabinets while keeping wiring complexity manageable. Combined, these features make the GE IS200VCMIH2BEE a reliable cornerstone for any industrial automation system.

Technical Specifications Table

| Specification | Detail |

|---|---|

| Model | GE IS200VCMIH2BEE |

| Brand | GE Automation / GE Fanuc |

| Series | Series 90-30 |

| Module Type | Digital Input/Output |

| Input Voltage Range | 24V DC |

| Output Voltage | 24V DC / Relay Output |

| Operating Temperature | 0–60°C |

| Storage Temperature | -20–70°C |

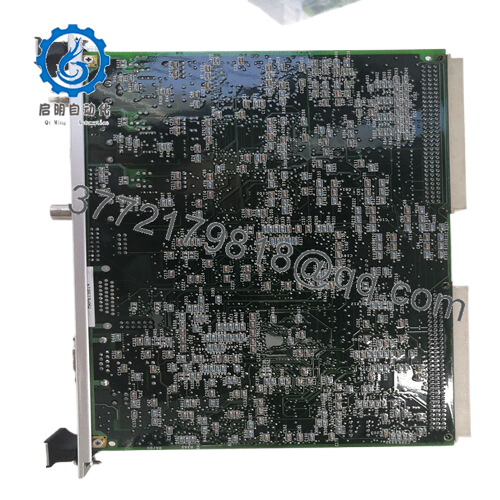

| Mounting | DIN Rail / Panel Mount |

| Communication Interface | Series 90-30 Backplane |

| Response Time | <2 ms per channel |

| Diagnostics | LED status indicators |

| Dimensions | 120mm x 30mm x 90mm |

Installation & Maintenance Insights

Installing the GE IS200VCMIH2BEE is straightforward when following standard Series 90-30 PLC practices. Begin by powering down the control panel and ensuring the backplane is free of dust or debris. The module slides securely into its slot with minimal force, and locking clips prevent accidental dislodging during operation. Always ensure polarity and signal connections align with manufacturer documentation to avoid miscommunication between the controller and field devices.

Regular maintenance is typically limited to visual inspections and cleaning. Dust accumulation on connectors can degrade signal integrity, so periodic wipe-downs with dry, anti-static cloths are recommended. Additionally, verify LED indicators during routine checks—blinking patterns quickly highlight channel failures or communication issues. In plants with high vibration or extreme temperatures, consider securing adjacent modules with shock-absorbing mounts for extra resilience.

Technicians frequently note that pre-labeling wires and connectors during installation significantly reduces troubleshooting time later. Leveraging the module’s built-in diagnostics, engineers can track performance trends and preemptively replace modules before a failure impacts production.

Product Role & System Fit

At its core, the GE IS200VCMIH2BEE functions as a bridge between sensors, actuators, and the PLC’s central processor. It handles input signals from various field devices and transmits them accurately to the control system. Equally, it manages output signals, ensuring actuators, alarms, and motors respond appropriately to automation logic.

Compatibility is a key advantage. The module fits seamlessly within the Series 90-30 PLC ecosystem, communicating via the backplane with minimal latency. Engineers often rely on its versatility to integrate new processes into existing control architectures without redesigning the entire panel. Its modular nature allows expansion of I/O points incrementally, offering cost-effective scalability.

Another important consideration is signal integrity. By isolating input and output circuits and providing robust protection against noise, the GE IS200VCMIH2BEE helps prevent spurious signals that could otherwise disrupt automated sequences. In high-speed manufacturing or critical processing environments, this reliability is essential, reducing waste, downtime, and safety risks.

Related Models

- GE IS200VCMIB2BEE – Similar I/O module with slightly fewer input channels.

- GE IS200VCMIP2BEE – Supports both digital and analog signals for hybrid applications.

- GE IS200VCMIM2BEE – Offers extended operating temperature range for extreme environments.

- GE IS200VCMIE2BEE – Compact version for limited panel space installations.

- GE IS200VCMIH3BEE – Enhanced response speed for high-frequency automation tasks.

- GE IS200VCMIA2BEE – Relay output variant suitable for heavy load control.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626