Description

Real-World Use & Application Scenarios

Where is this product used and why?

In GE Speedtronic Mark VI systems, the IS200VAICH1D analog input board serves as a dense, high-precision interface between process sensors and the turbine control logic. It handles multiple analog signals—voltage, current, and other process variables—allowing the control system to monitor turbine speed, vibration, pressure, temperature, and valve positions with high fidelity. Applications span industrial power generation, oil and gas pumping stations, and large compressor facilities where rapid, deterministic data acquisition translates into stable protection and finely tuned control loops. The VAIC board is chosen for its compatibility with the Mark VI rack, its ability to independently condition and digitally convert numerous analog signals, and its role in ensuring accurate measurements feed protection and supervision routines. This model is typically deployed as part of a modular rack where each VAIC card contributes to a scalable input/output architecture, making it a common reference in procurement briefs seeking reliable analog I/O within GE’s turbine control ecosystem.

Product Introduction & Positioning

What it is, where it fits, and why it matters

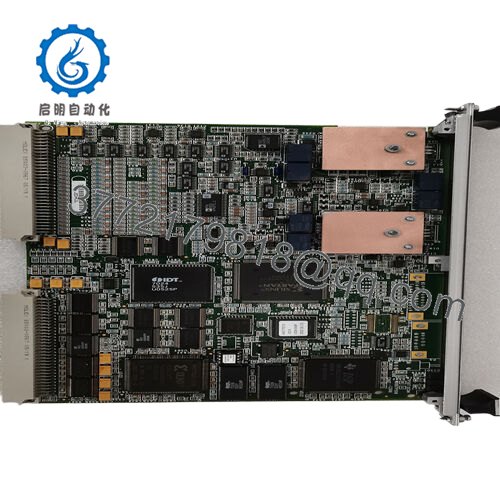

The IS200VAICH1D is a VME-based analog input module used inside GE’s Mark VI turbine control framework. It accepts multiple analog signals, converts them with high resolution, and forwards them to the central control processor or companion I/O modules. As part of the IS200/Mark VI family, it sits alongside other VAIC cards to form a complete analog input subsystem for the turbine control loop. This board is valuable to engineers and integrators because it provides a rugged, plug-in interface that supports scalable channel counts, precise calibration, and straightforward integration with the rack’s backplane and terminal boards. Its design emphasizes reliability in demanding environments, with attention to signal integrity, timing consistency, and compatibility with GE’s configuration tools and diagnostics.

Key Technical Features & Functional Benefits

Performance, rugged design, and integration

The IS200VAICH1D typically delivers a multi-channel analog input solution with high-resolution A/D conversion, enabling accurate representation of process signals for the Mark VI control algorithms. It supports a defined channel count (commonly around 20 AI channels) and integrates with terminal boards to route signals into the processor bus, facilitating synchronized sampling across channels. The card is built for industrial environments, featuring rugged construction, vibration tolerance, and EMI considerations. Its compatibility with GE’s PCM/engineering toolchain and backplane architecture streamlines commissioning, calibration, and maintenance. The VAIC’s ability to condition, route, and digitize signals with deterministic timing contributes to stable control loops, precise alarms, and reliable protective actions across the turbine system.

Detailed Technical Specifications

Display technical information in a clean table. While exact values vary with revision, typical specs include:

Parameter | Value

Model | IS200VAICH1D

Brand | General Electric

Type | Analog Input Card (VME)

Channels | Typically up to 20 AI inputs; 4 AO outputs (config dependent)

Resolution | 16-bit ADC (typical)

Input Types | Voltage, 4–20 mA, 1 mA, etc. (configurable per channel)

Backplane | VME-based; compatible with Mark VI rack

Power Supply | Derived from system backplane; auxiliary supply per rack as required

Operating Temperature | -40°C to +85°C (rack/ enclosure dependent)

Mounting | VME card in control rack

Dimensions | Standard VME card footprint

Weight | Varies by enclosure

Interfaces | Terminal boards (e.g., TBAIHx), backplane signals

Certifications | GE/Industry-compliant testing for turbine controls

Cooling | Passive or forced-air within the enclosure

Environmental Rating | Designed for harsh industrial environments

Notes | Consult the exact revision sheet for channel counts and supported input types

- IS200VAICH1D

- IS200VAICH1D

Related Modules or Compatible Units

5–8 related models and connections

IS200VAICH1DAA – Alternate revision with identical AI/AO layout, differing in firmware or header options.

IS200VAIH1D – Similar analog input card variant within the VAIC family.

IS200VAIH1D – (If present in your catalog) another hardware revision with adjusted channel mapping.

IS200TBAIH1B – Terminal board variant to connect sensors to the VAIC input channels.

IS200PVBXH1 – Power/voltage conditioning board that often pairs with VAIC for complete input conditioning.

IS200OSTXH1D – On-site diagnostic/telemetry option compatible with VAIC-equipped racks.

IS200LBBXH1D – Local bus bridging for expanded network topology with VAIC.

IS200MGAH1D – Multi-group analog interface module that can extend the input capabilities of the Mark VI rack.

Installation Notes & Maintenance Best Practices

Two paragraphs with practical guidance

Pre-installation planning should verify rack space, backplane compatibility, and grounding schemes to minimize EMI on analog signals. Confirm the channel configuration, input adapters, and terminal boards align with the plant’s sensor network and calibration procedures. Plan for proper cable routing to reduce cross-talk, ensure secure mechanical mounting, and verify that the system power and auxiliary supplies meet the rack’s requirements. Commissioning should include channel-by-channel calibration, integrity checks on backplane signaling, and validation of timing across all AI inputs. Document firmware revisions and configuration maps to support future upgrades, and establish a routine of periodic checks on signal integrity, connector cleanliness, and environmental conditions inside the control cabinet.

In maintenance windows, perform visual inspections of connectors and cables, verify that calibration data remains current, and monitor for drift in sensor readings through routine diagnostics. Schedule firmware and software updates per GE’s service bulletins and ensure logbooks capture changes to channel configurations, alarm setpoints, and interconnects with other I/O subsystems. Remote diagnostics can accelerate fault isolation for AI channels and reduce maintenance downtime by enabling proactive interventions.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626