Description

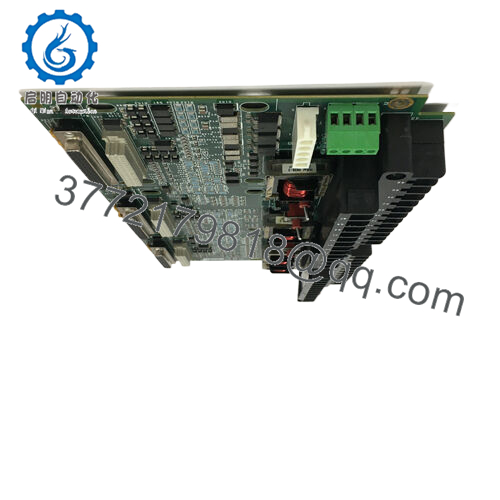

Product Model: IS200TSVCH1AED

Product Brand: GE (General Electric)

Product Series: GE Mark VI / Mark VIe (Speedtronic)

Product Features:

- Dual-channel bidirectional servo current outputs and integrated LVDT inputs

- Supports pulse (rate) inputs, external trip logic, and embedded relays

- Hot-swappable, compatible with redundancy (Simplex, Dual, TMR)

- Rugged design for harsh industrial and turbine environments

- IS200TSVCH1AED

Product Role & System Fit

In a GE Speedtronic turbine control architecture, the IS200TSVCH1AED functions as the TSVC (Turbine Servo / Valve Control) terminal board — a critical bridge between the control logic and the field actuators, sensors, and protection circuits. It doesn’t execute high-level algorithms by itself, but it manages servo output currents, LVDT feedback, pulse inputs, and trip signals. Its tight integration ensures that control loops remain responsive and safe.

As the interface card for servo valves, the IS200TSVCH1AED works directly with electro-hydraulic actuators. It receives commands from higher-level GE Mark VI or Mark VIe process controllers (or I/O packs) and translates those into precise current outputs. Simultaneously, it monitors valve position by reading LVDT inputs. On abnormal conditions, it can generate safety trip signals via embedded relays, integrating into the protection chain.

This board is built to slot into the GE modular control rack or panel arrangement. It fits alongside other IS200-series modules and interacts with redundant configurations (like TMR) to maintain continuous operation even if one channel or board fails. In many installations, it is paired with a servo driver (e.g. PSVO or WSVO packs) and other I/O modules.

In modern gas and steam turbine plants, this module is essential. When controlling fuel valves, bypass valves, or blade actuators, precise and synchronized actuation is critical. The IS200TSVCH1AED ensures the timing, feedback, and safety interlocks needed for stable turbine operation in real-world conditions.

Applications & Industry Context

Large-scale power plants, combined cycle plants, gas turbines, steam turbines—all of these settings demand rigor in actuation control. The IS200TSVCH1AED is often found in power generation facilities where GE’s Mark VI / Mark VIe control systems are deployed. In these plants, it helps manage servo valves that modulate fuel, steam admission, or bypass flow, all while ensuring safety interlocks are honored.

On offshore oil and gas platforms, where turbines drive compressors or generators in harsh marine environments, this board’s ruggedness and reliability are vital. Similarly, in petrochemical plants, large compressors may be driven by gas turbines; the IS200TSVCH1AED ensures the actuator interface and sensors remain in sync with the control system.

Refinery utilities, cogeneration plants in chemical factories, or even hypercritical industrial installations—where precision control and fail-safe actuation matter—benefit from this module. Its support for redundancy (Simplex, Dual, Triple Modular Redundancy) makes it suitable where uptime is non-negotiable.

That said, because it interfaces with servo valves and protection circuits, its installation often coincides with elaborate safety reviews, cabling audits, and environmental control strategies (temperature, grounding, noise immunity).

Technical Features & Benefits

Let’s dive into what makes the IS200TSVCH1AED special:

Servo Current Output / Control

This board provides two bidirectional servo current outputs (selectable in multiple ranges) to drive actuators. These outputs respond to control signals, enabling precise valve positioning and actuation speed control.

LVDT / Position Feedback Inputs

It supports eight LVDT winding inputs, enabling closed-loop feedback of valve position. This allows the system to continuously monitor actual actuator position and correct for overshoot or drift.

Pulse / Rate Inputs

Two pulse rate (or speed) inputs (magnetic or TTL) are supported for functions like fuel flow measurement or rotational speed detection.

Embedded Relays & Trip Logic

The board incorporates nine magnetic relays arranged in trip/voting circuits to trigger external protection devices (ETD – electrical trip device) under fault conditions. It’s designed to interlock with protection logic.

Excitation / Power

Four isolated excitation sources and additional non-isolated sources allow LVDT supply flexibility. The board runs off a 28 V DC supply via a connector (J28).

Control Architecture Support

Supports Simplex, Dual, and TMR (Triple Modular Redundancy) configurations, enabling fault-tolerant operation. In TMR setups, voting logic ensures that a single module failure doesn’t lead to unsafe actions.

Diagnostic & Configurability

Diagnostic signals (e.g. L#DIAG PSVO) provide status of servo modules. The board also features configurable jumper settings (for coil current, modes, etc.).

Environmental & Reliability

Rated for industrial temperature ranges (–30 °C to +65 °C) and rugged applications. Designed for turbines and associated control cabinets.

These features mean the IS200TSVCH1AED is not just a passive interface—it’s a heart of safe, precise actuation control in demanding industrial environments.

Technical Specifications Table

| Specification | Detail / Value |

|---|---|

| Model | IS200TSVCH1AED |

| Brand | GE (General Electric) |

| Series | GE Mark VI / Mark VIe (Speedtronic) |

| Module Type | TSVC (Servo / I/O) Terminal Board |

| Servo Outputs | 2 bidirectional current outputs (various ranges) |

| LVDT Inputs | 8 winding inputs, supporting 1–4 LVDT/servo circuits |

| Pulse / Rate Inputs | 2 (magnetic or TTL) |

| Relays | 9 magnetic relays (trip / voting circuits) |

| Excitation Sources | 4 isolated + 2 non-isolated supply lines |

| Power Supply | 28 V DC via J28 connector |

| Control Modes | Simplex, Dual, TMR |

| Diagnostic Signals | Yes, e.g. L#DIAG PSVO |

| Operating Temperature | –30 °C to +65 °C |

| Mounting | Rack or panel / via terminal blocks |

| Installation | Interface board for GE Mark VI / VIe control racks |

| Communication / Interface | Connection to PSVO I/O packs, WSVO servo drivers, trip circuits |

Installation & Maintenance Insights

Installing a IS200TSVCH1AED demands careful attention — after all, it’s the gateway between logic and physical actuation in turbine systems.

Mounting & Positioning

The board is typically installed in a control rack or panel adjacent to other Mark VI / Mark VIe modules. It can mount via terminal blocks or rack slots. Ensure vibration resistance in mounting hardware.

Power & Grounding

It requires a stable 28 V DC supply, usually tied to the control system’s power bus. Grounding must be solid; improper bonding can compromise servo signals and invite noise. All shields in sensor wiring must route back to a single grounding point to prevent ground loops.

Wiring & Signal Cabling

- Servo Outputs: Use twisted pair or shielded cable, sized per current rating.

- LVDT Feedback: Shielded wiring is vital — noise on position lines can degrade control precision.

- Pulse Inputs: Correct termination and shielding are required for TTL or magnetic signals.

- Trip / Relay Outputs: Ensure wiring meets safety and trip logic requirements, with proper isolation.

Testing wiring with continuity checks and insulation resistance before powering is a must.

Redundancy / Hot Swap Scenarios

In redundant or TMR configurations, the IS200TSVCH1AED may be replaced under controlled conditions. Use proper ESD handling. When replacing, ensure that all signals, jumper settings, and board revisions match the system to prevent mismatches.

Diagnostics & Monitoring

Use GE’s configuration tools (such as ToolboxST) to monitor L#DIAG output, check relay states, validate servo commands, and detect anomalies. Periodic checks help detect drift, stuck relays, or cable degradation before failure.

Preventive Maintenance

- Periodically inspect connectors for corrosion or loose pins.

- Clean dust from ventilation or contact surfaces.

- Trigger self-tests or diagnostic commands during plant outages.

- Ensure firmware compatibility with control modules and servo drivers.

In one field case, a power plant technician replaced a failing IS200TSVCH1AED mid-cycle (in a controlled maintenance window). Thanks to redundancy and careful wiring, the turbine continued safe operation during the swap — and diagnostics afterward confirmed seamless continuity.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626