Description

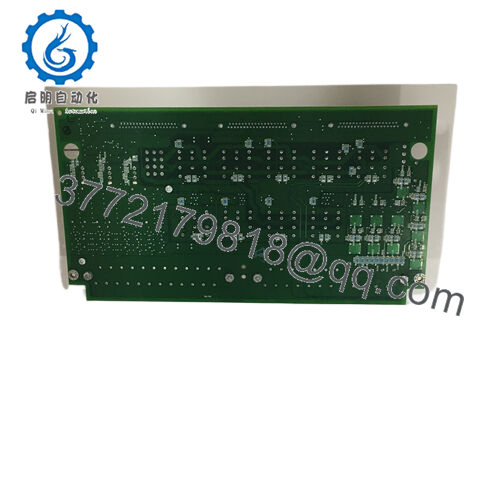

GE IS200TRPGH1BDD S1C5029 is a triple redundant protection gateway (TRPG) module designed specifically for GE’s Mark VI and Mark VIe turbine control systems. As a TRPG module, it is a critical safety component in these advanced control systems.

IS200TRPGH1BDD S1C5029

In the architecture of Mark VI and Mark VIe systems, GE IS200TRPGH1BDD S1C5029 occupies a central position in the safety critical protection logic. It interfaces with various sensors that monitor turbine parameters and sends emergency stop commands to actuators when needed. This module adopts a triple redundancy design, which means there are three independent processing channels working in parallel. This redundant design significantly improves the reliability of the protection system. If one channel fails, the other two channels can continue to operate to ensure that safety functions are not affected.

IS200TRPGH1BDD S1C5029

Main features and advantages:

From a functional perspective, the GE IS200TRPGH1BDD S1C5029 is powerful. It adopts the third mock examination redundancy (TMR) technology and has three independent processing channels. This design ensures maximum reliability. This module adopts a 2-out-of-3 (2oo3) voting logic. This means that in order to make a decision, at least two of the three channels must reach a consensus. This method can effectively prevent false tripping while maintaining a high level of safety. For example, if a sensor malfunction causes an incorrect reading in one channel, the correct readings in the other two channels will take precedence to prevent unnecessary downtime.

In terms of hardware design, this module is specifically designed to withstand the harsh conditions commonly found in power plants and industrial environments. It has a sturdy structure that can withstand vibrations, temperature changes, and electrical noise. Its compact size also makes it easy to install in control cabinets, even in places with limited space. The connectors and components of the module are designed for long-term durability, reducing the need for frequent replacement.

Compatibility is a major advantage of this module. It seamlessly interfaces with other protection modules in the Mark VI and Mark VIe ecosystems, such as IS200TREGH1A and IS200TBAIH1B. It also works in conjunction with GE’s ToolboxST engineering software, enabling engineers to effectively configure, monitor, and troubleshoot module failures. This interoperability helps create comprehensive and integrated turbine control and protection systems.

Long term reliability is a key aspect of GE IS200TRPGH1BDD S1C5029. It has a built-in self check function that can continuously monitor its own status. The LED indicator lights on the module provide visual prompts about power status, channel status, and fault detection. In addition, the module supports hot swapping, which means it can be replaced without shutting down the entire turbine system. This feature can minimize downtime during maintenance or in the event of module failure, ensuring continuous operation of power generation or industrial processes.

IS200TRPGH1BDD S1C5029

Technical specifications:

Model IS200TRPGH1BDD S1C5029

Brand GE

Type Triple Redundancy Protection Gateway (TRPG) Module

Compatible with GE Mark VI and Mark VIe turbine control systems

Voting logic 2 out of 3 (2oo3)

Processing channel quantity 3

Connect sensors for inputting and monitoring turbine parameters (such as speed, temperature, vibration sensors)

Output control emergency stop actuator

Working temperature -20 ° C to 60 ° C

Installation method designed for standard DIN rail installation in control cabinets

Built in self-test is

Hot swappable is

Certification CE, UL

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

IS200TRPGH1BDD S1C5029

Application areas:

Gas power plants and steam power plants are highly dependent on GE IS200TRPGH1BDD S1C5029. Gas turbines are efficient power generation equipment, but their operation requires strict control and protection. This module is integrated into turbine control systems, such as GE’s famous Mark VI and Mark VIe systems. It continuously monitors key parameters of the turbine, such as speed, temperature, and vibration. In gas turbines, excessive rotational speed may lead to catastrophic mechanical failures, while abnormal temperature or vibration may indicate component wear or imminent failure. GE IS200TRPGH1BDD S1C5029 is designed to detect any deviation from the normal operating range. If an unsafe situation is detected, it will immediately trigger an emergency stop to prevent potential disasters from occurring.

Steam turbines are also widely used in the field of power generation and require this module. Steam turbines operate under high-pressure steam, and any malfunction could cause significant damage to the turbine itself and the entire power plant infrastructure. GE IS200TRPGH1BDD S1C5029 ensures that the operation of the steam turbine remains within a safe range, preventing overspeed, overheating, and other hazardous situations from occurring.

In addition to the power generation field, GE IS200TRPGH1BDD S1C5029 is also applied in industrial processes, where turbines are used for mechanical drive. For example, in petrochemical plants, turbines may be used to drive compressors that transport gases. In this case, the module helps to maintain the safe operation of the turbine, ensuring the continuity and reliability of the entire production process. Any interruption in the operation of the turbine may result in costly production shutdowns and may pose safety hazards to the factory.

IS200TRPGH1BDD S1C5029

Related products:

GE IS200TREGH1A – This protection module works closely with GE IS200TRPGH1BDD S1C5029 in Mark VI and Mark VIe systems. They together form an integrated protection solution for the turbine, with IS200TREGH1A handling certain aspects of the protection logic, complementing the functionality of GE IS200TRPGH1BDD S1C5029.

GE IS200TBAIH1B – It is compatible with GE IS200TRPGH1BDD S1C5029 and is part of the module kit in Mark VI and Mark VIe systems. It may participate in signal conditioning or additional control functions to improve the overall performance of the turbine protection system.

GE Mark VI VTur board – interfaces with GE IS200TRPGH1BDD S1C5029 in the Mark VI system. The VTur board provides certain control signals and data, which GE IS200TRPGH1BDD S1C5029 uses to make decisions regarding turbine protection and operation.

GE Mark VIe PTur Packs on TTURH1C – In the Mark VIe system, these packs control GE IS200TRPGH1BDD S1C5029. They send and receive signals to modules to achieve coordinated operation within the turbine control system.

GE ToolboxST Engineering Software – Although not a hardware module, this software is crucial for configuring and monitoring GE IS200TRPGH1BDD S1C5029. Engineers use it to set module parameters, view diagnostic information, and make adjustments to ensure optimal performance.

IS200TRPGH1BDD S1C5029

Installation and maintenance:

Before installing GEIS200TRPGH1BDD S1C5029 , the integrator should thoroughly evaluate the control cabinet environment. Ensure that the control cabinet has sufficient space to accommodate modules and avoid overcrowding, as proper ventilation is crucial for module performance. Adequate clearance should be maintained around the module for easy operation during maintenance. Grounding is also a key consideration factor. Appropriate grounding connections must be established to protect the module from surge effects and ensure the safety of the entire system. When connecting modules to sensors and actuators, strictly follow the wiring diagram provided by GE to avoid connection errors that may cause malfunctions.

For maintenance, it is recommended to conduct regular visual inspections. At least once a month, check for physical damage such as cracks or loose connections on the module casing. It is recommended to conduct regular diagnostic tests every quarter and use appropriate testing equipment to verify the integrity of module functionality. Due to the built-in self-test function of the module, the self-test results should be checked regularly. If any issues are detected, please follow GE’s troubleshooting guide. Firmware updates are also important. GE may release firmware updates to improve module performance, add new features, or address security vulnerabilities. The integrator should be aware of these updates at all times and install them carefully according to the provided instructions.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626