Description

In the high-stakes arena of turbine control within industrial automation, where Mark VIe systems must capture discrete feedback from field contacts like limit switches, vibration sensors, or emergency trips without succumbing to electromagnetic interference or contact bounce, engineers often face the chaos of unreliable signal capture that leads to missed faults, erroneous interlocks, or delayed protective actions—potentially escalating into turbine trips, grid instability, or safety breaches in power generation facilities. This reliability gap widens in triple modular redundant (TMR) architectures, where simplex boards introduce single points of failure or demand excessive wiring for failover, complicating diagnostics in hot, vibratory enclosures and eroding process control precision amid 60 Hz noise from generators or inductive loads. The GE IS200TDBTH6ACD confronts this as a TMR-configured discrete input/output terminal board for the Mark VIe platform, providing 24 isolated channels for dry/wet contacts with redundant termination to ensure fault-tolerant signal routing, upholding high reliability without the vulnerabilities of non-synchronized interfaces.

Consider safeguarding a gas turbine enclosure or retrofitting a steam plant’s overspeed protection: without a TMR-capable board, you’re reliant on non-redundant terminals that amplify EMI risks from nearby exciters or require custom debouncing circuits, inflating cabinet density and commissioning timelines. The GE IS200TDBTH6ACD becomes essential in these modular integration efforts, bolting into I/O assemblies to interface with PDIA or YDIA packs for debounced 24 VDC inputs/outputs, directly enabling goals like seamless system stability and sub-10 ms fault propagation in industrial automation. Its high-density screw terminals support TMR voting for triple-voted signals, minimizing false positives while embedding surge protection to weather transients from field relays.

In process control environments where critical system uptime translates to uninterrupted megawatt output, the GE IS200TDBTH6ACD excels with its ATEX Zone 2 compliance that permits deployment in hazardous areas, perfect for teams leveraging ToolboxST for configuration where synchronized channels preempt diagnostic dead ends. By facilitating peer-to-peer IONet redundancy without additional gateways, it reduces engineering overhead for validation in multi-rack setups, allowing emphasis on turbine optimization over signal chasing in EMI-heavy bays and aligning with searches for Mark VIe terminal boards, TMR discrete I/O, or robust turbine control interfaces.

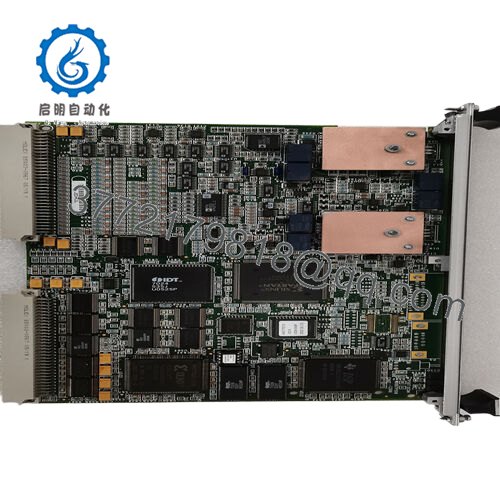

Bolted to the Mark VIe I/O rack alongside packs like the IS220PDIAH1B, the GE IS200TDBTH6ACD functions as the frontline termination hub in your TMR stack, routing 24 discrete signals—12 inputs and 12 outputs in triple-voted groups—through isolated barriers to the acquisition board for Ethernet packetization over the IONet backbone. It mounts in ventilated assemblies, drawing 24 VDC from the system bus while exposing rows of 2.5 mm² screw terminals for field wiring, positioning it at the field layer below signal processing but above raw transducers, where ToolboxST maps channels for wet/dry modes or debounce times up to 50 ms without hardware swaps.

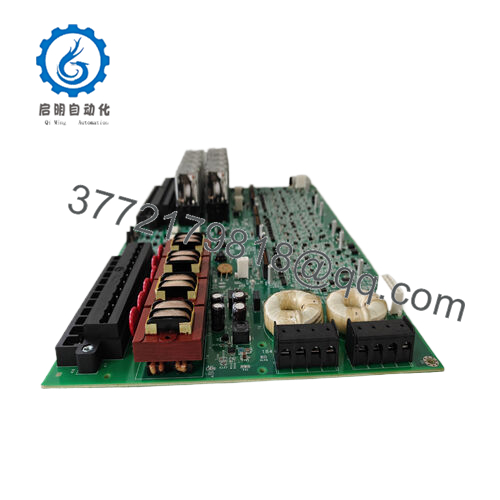

Wiring engages at color-coded terminals: inputs accept 24 VDC wetting from external sources or board-supplied current, applying mechanical isolation per trio for TMR consensus before relaying states to the controller, while outputs drive relays with flyback diodes for inductive suppression. In the automation hierarchy, the GE IS200TDBTH6ACD synchronizes with VPRO or TREG boards for protection loops, backing redundancy via dual IONet paths with <5 ms failover and fault latching like stuck contacts to the event buffer, viewable in CIMPLICITY. Its 2500 V channel isolation shields logic from field grounds, suiting distributed IONets where remote terminals extend via fiber without latency buildup. Hot-swappable with locking hardware, it fits hybrids blending Mark VIe with RXi controllers, delivering voted integrity for trip signals sans the bounce blunders of simplex rivals.

| Specification | Details |

|---|---|

| Model Number | IS200TDBTH6ACD |

| Brand | GE (Emerson) |

| Type | TMR Discrete Input/Output Terminal Board |

| Input Voltage | 24 V DC nominal (22.5-28.6 V range) |

| Operating Temp Range | -40°C to +70°C |

| Mounting Style | Mark VIe I/O rack assembly |

| Dimensions | 240 mm x 170 mm x 80 mm (W x H x D) |

| Weight | 1.5 kg |

| Interface/Bus | Screw terminals, IONet (via packs) |

| Compliance | CE, UL, ATEX Zone 2 |

| Supported Protocols | Ethernet (EGD, SRTP via packs) |

| Typical Power Draw | 5 W |

Selecting the GE IS200TDBTH6ACD yields termination tenacity, its TMR isolation and surge clamping delivering performance consistency that repels generator hum or relay chatter, where non-voted boards might phantom—here, triple consensus sustains interlock accuracy in exciter vaults without spurious shutdowns.

Maintenance condenses to terminal audits with no pack pulls; Ethernet logs from ToolboxST unveil contact trends on-demand, trimming outage hunts versus field-foraging. Built for enclosure endurance with conformal coatings against soot and shocks to 5G, it pledges long-term performance through thermal tides, while locking barriers deter loose wires in vibratory mounts.

The core payoff lies in engineering parsimony: 24-channel TMR density quells wiring webs for voted apps, easing spares for Mark VIe fleets. In turbine safeguarding, it pares failover fixtures, muting setup snarls and lapse lairs. For resilience-rooted ops, the GE IS200TDBTH6ACD extends control canopy, gating predictive probes sans terminal tweaks—reaping from voted vigilance and innate insulators.

In aeroderivative turbine skids, the GE IS200TDBTH6ACD terminates vibration pickups amid compressor whine, routing triples to defy EMI in harsh bays for fast data cycles that cue bearings, cementing critical system uptime through rack relays in modular aero chains.

Nuclear steam bypass panels harness it for valve position discretes under radiation veils, latching states in shielded silos for process control keenness and high reliability in baseload beats with IONet-buffered grace.

Offshore gas compressor trains deploy the GE IS200TDBTH6ACD in module housings, capturing surge alarms via ATEX ties in brine blasts, upholding continuous operations through debounced draws in heave-hammered hulls.

- IS200TDBTH6ACD

- IS200TDBTH6ACD

IS200TDBTH6A – Base revision without ‘CD’ enhancements for standard TMR in non-hazardous setups.

IS200TDBSH6A – Simplex counterpart for non-redundant discrete termination in lighter loads.

IS220PDIAH1B – Matching input pack for acquisition pairing in IONet extensions.

IS200TBCIH2C – High-density terminal alternative for expanded I/O routing in racks.

IS200TPROH1C – Protection board companion for trip signal integration.

IS200TREAH1A – Emergency trip terminal for failover in safety-critical chains.

IS400TDBTH6A – EX2100 series equivalent for legacy turbine migrations.

Before bolting the GE IS200TDBTH6ACD into your Mark VIe assembly, confirm firmware—below 14.0 limits EGD, so pull the patch from Emerson’s portal. Map channel trios in ToolboxST to shun mismatches; orphan votes idle signals slyly. Rack voltage skimps not—its 5W draws steady, but multimeter the 24V under phantom pulses for sag-free. For wet inputs, fuse external wetting at 10 mA per group to fend faults, and braid shields beyond 100 ft to tame transients. Torque screws to 1.2 Nm pre-juice, as under-tight breeds intermittents.

In service, the no-LED design leans on pack indicators: green IONet for synced terminals, amber FLT for wiring woes via event logs. Quarterly, cycle contact simulators across trios to vet voting shy of 1 ms skew, nipping drift early. Cinch barriers in quake zones annually, and archive configs via Ethernet pre-upgrade. Knot TMR faults to controller alarms for dashboard dings, syncing with enclosure sweeps to lock sub-5 ms propagation, dodging discord before it derails drives.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626