Description

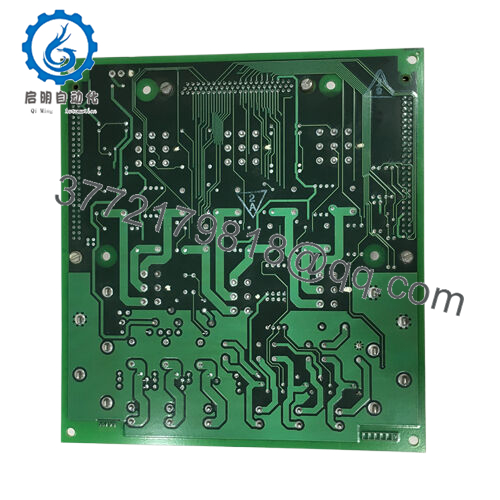

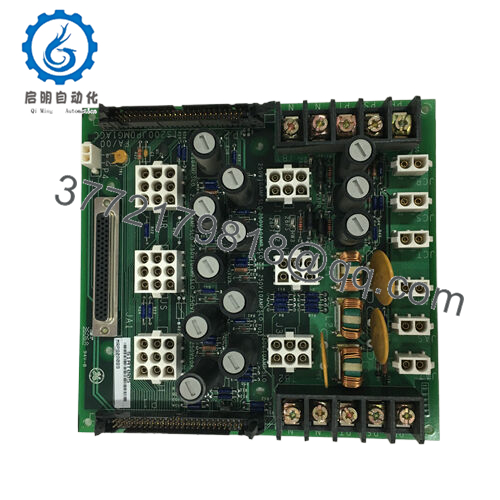

GE IS200JPDMG1ACC S1AT005 is a digital input/output (I/O) module that is part of GE’s advanced Mark VIe gas turbine control system. This control system is widely used in power generation and industrial applications due to its high performance capability. In the overall control system architecture, this module serves as a key link between field devices and the central control unit.

IS200JPDMG1ACC S1AT005

It receives digital signals from various sensors, including limit switches that detect the position of mechanical components, pressure switches that monitor fluid pressure, and temperature sensors that track thermal conditions. Then, these signals are processed by the module and transmitted to the central control unit for further analysis and decision-making. On the contrary, the module receives control signals from the central unit and uses these signals to drive digital actuators such as relays and solenoid valves. These actuators then control the operation of various devices, such as valves that regulate fluid flow and motors that drive mechanical processes.

IS200JPDMG1ACC S1AT005

Main features and advantages:

From a functional perspective, the GE IS200JPDMG1ACC S1AT005module performs excellently. It has high-speed data processing capabilities and can quickly respond to changes in on-site signals. For example, in a gas turbine, if there is a sudden change in exhaust temperature, the module can detect this change within milliseconds and transmit the relevant information to the central control unit. This fast response time is crucial for maintaining the safe and efficient operation of the turbine. This module is designed to handle a large number of digital I/O channels. It typically has multiple configurable input channels to accept different types of digital signals, such as dry contacts, NPN, or PNP signals. At the output end, the channel can drive various loads, including relays and solenoid valves, with sufficient current and voltage ratings. This versatility makes it an ideal choice for controlling various field devices in different industrial applications.

The hardware design of GE IS200JPDMG1ACC S1AT005 is designed to withstand the harsh conditions commonly found in industrial environments. It is enclosed in a sturdy casing to protect internal components from dust, moisture, and vibration. In addition, the module is designed to be immune to electromagnetic interference, which is common in industrial environments. This ensures that the module can operate reliably even in the presence of strong electric and magnetic fields. It is usually designed to be easy to install in standard control cabinets, using a simple installation mechanism such as DIN rail installation, which can achieve fast and safe fixation.

Compatibility is one of the main advantages of the GE IS200JPDMG1ACC S1AT005 module. It is fully compatible with other components of the GE Mark VIe control system, ensuring seamless integration throughout the entire control setup. This compatibility also extends to communication protocols. It can communicate with the central control unit and other modules using industry standard protocols such as Ethernet/IP and Profibus DP. This makes integration with third-party devices and systems easier, providing users with greater flexibility in designing control solutions. Whether connecting specific brands of sensors or actuators, or integrating with larger factory level automation networks, the compatibility features of this module make it a versatile choice.

Long term reliability is a key focus in the design of the GEIS200JPDMG1ACC S1AT005 module. This module is equipped with redundant power supplies, which means that in the event of a power failure, another power supply can take over to ensure continuous operation. This redundancy is crucial for applications that require uninterrupted control, such as power plants. It also has a built-in self diagnostic function. These functions continuously monitor the health status of the module, checking for issues such as overheating, component failures, and communication problems. If a problem is detected, the module can generate an alert and take corrective measures, such as isolating the faulty component or switching to a redundant backup. This proactive self-monitoring and self correction method minimizes downtime to the greatest extent possible and helps maintain the overall integrity of the control system.

IS200JPDMG1ACC S1AT005

Technical specifications:

Model IS200JPDMG1ACC S1AT005

Brand GE

Type: Digital Input/Output (I/O) Module

Input voltage 24 V DC (± 10%)

Input signal type: dry contact NPN、PNP

Communication protocols Ethernet/IP, Profibus DP

Installation type DIN rail

Working temperature -20 ° C to 60 ° C

Humidity range 5% -95% without condensation

Redundant feature redundant power supply

Self diagnostic feature monitoring for overheating, component failures, and communication issues

Contact Us

Phone:+86 16626708626

WeChat/WhatsApp:+86 16626708626

Email: 3772179818@qq.com

IS200JPDMG1ACC S1AT005

Application areas:

In power plants, especially those that rely on gas turbines, GE IS200JPDMG1ACC S1AT005 is an important component of the control infrastructure. Gas turbines operate under extreme conditions of high temperature and pressure, and precise control of fuel injection and combustion processes is crucial for maximizing power output, optimizing fuel efficiency, and reducing harmful emissions. This module participates in the fuel control system of gas turbines and can accurately adjust the fuel flow entering the combustion chamber, ensuring that the fuel air mixture ratio is accurately maintained at the optimal state. In this way, it enables gas turbines to operate at maximum efficiency both during base load generation and in response to fluctuations in electricity demand. For example, when the demand for electricity suddenly increases, the module can quickly adjust the fuel flow to meet the load demand while maintaining stable combustion, thereby avoiding any interference with the power supply.

Industrial manufacturing facilities using high-power machinery have also benefited greatly from the GE IS200JPDMG1ACC S1AT005 module. In large-scale compressor applications in the oil and gas industry, or heavy-duty motor applications in mining operations, the motor control center typically integrates this module. It is responsible for controlling the start, stop, and speed regulation of these motors. In mining operations, large conveyor belt motors need to start smoothly to avoid mechanical stress on the conveyor belt and the motor itself. The GE IS200JPDMG1ACC S1AT005 module is programmable to manage the increase and decrease of motor speed, reduce wear, and extend equipment lifespan. This not only improves the reliability of the manufacturing process, but also reduces maintenance costs and unexpected downtime.

IS200JPDMG1ACC S1AT005

Related products:

GE IS200JCDAG1AAB is an analog I/O module. In power plants, when GE IS200JPDMG1ACC S1AT005 controls the on/off operation of valves and other digital based devices, IS200JCDAG1AAB can be used to accurately control the position of regulating valves based on analog signals from sensors. This combination allows for more comprehensive control over digital and analog based processes.

GE IS200JCMAG1A may be a communication module. It can enhance the communication capability of the system by expanding network coverage, enabling GE IS200JPDMG1ACC S1AT005 to communicate with more remote devices or improve data transmission speed and reliability within the control system. This is particularly useful in large industrial factories where there are many on-site equipment distributed over a wide area.

GE IS200JCSAG1B may be a system specific module designed specifically for Mark VIe control systems. It may provide additional features such as system configuration management or support for advanced control algorithms, further optimizing the performance of the entire control system.

GE IS200JESAG1A may be an expansion module. It can increase the number of I/O channels or add new features to existing settings. For example, in complex industrial processes that require connecting a large number of sensors, this module can be used to add more digital input channels and expand the monitoring capabilities of the system.

GE IS200JPCAG1A may be a module related to power supply. It can work in conjunction with GE IS200JPDMG1ACC S1AT005 to ensure stable power supply for modules and other connected devices. It may have functions such as power regulation and surge protection to protect sensitive electronic devices from electrical fluctuations and surges.

Installation and maintenance:

Before installing GE IS200JPDMG1ACC S1AT005 , several important pre installation precautions must be considered. Firstly, ensure that the control cabinet to be installed has sufficient space. The control cabinet should also be properly ventilated to prevent the module from overheating during operation, as overheating may lead to performance degradation or even component failure. The power supply of the control cabinet must be carefully checked to ensure that it meets the voltage and current requirements of the module. Grounding is crucial. Appropriate grounding connections must be established to protect the module from electrical surges and ensure accurate signal transmission. The grounding resistance should be within the range specified in the installation guidelines. In addition, it is necessary to verify the compatibility of the module with other components already installed in the control cabinet or to be connected to it. This includes checking for any potential electrical or mechanical conflicts that may arise during operation.

During maintenance, it is recommended to conduct regular visual inspections. Check the module at least once a month for any signs of physical damage. This includes checking for cracks in the casing, loose connectors, or any obvious signs of overheating such as discoloration or burn marks. Any visible issues should be addressed immediately to prevent further damage and potential system failures. Signal diagnosis should be conducted quarterly. This involves testing input and output signals to ensure their proper functioning. The signal received from the sensor should be compared with the signal processed by the module, and the accuracy of the control signal sent to the actuator should be verified. It is also important to keep the firmware of the module updated. GE will regularly release firmware updates, which may include bug fixes, performance enhancements, and new features. Timely firmware updates help keep GE IS200JPDMG1ACC S1AT005 running at its optimal level, ensuring continuous reliable performance and compatibility with the latest software and hardware components.

Other GE product models:

GE IS215WEPAH2B

GE 8910-PS-DC

GE DS3820PSCB1C1B

GE IC695ALG508

GE 8910-PS-DC

GE ACC-5595-208

GE IS420UCSBH3A

GE IC695CPE310

GE IC695CPE310

GE IS420UCSBH3A

GE 362A1052P104

GE IS220PDIAH1B

GE IS200TRTDH1D

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE Hydran M2-X M2X-O1-S1-A0-B0-C0-D0-P0-G0-VC0-V0-E0-M0-L0

GE IC697CPX928

GE IC697CPX928

GE IS220PDIAH1B

GE DS2020UCOCN1G1A

GE DS200SDCIG2AFB

GE DS200SDCIG2AFB

GE IC697CPX928

GE DS200TCEBG1BAA

GE MIVII1000E00HI00

GE IS200WNPSH1A

GE AL129A

GE IS420YDIAS1B

GE 04220FL11232A

GE DS3800NHVL

GE DS200SNPAH1AB

GE IS415UCVGH1A

GE ACC-5595-208

GE IS420UCSBH3A- REVB

GE IS200TBCIS2CCD

GE IS200TRLYH1BHH

GE IS220PDOAH1B

GE IS230TNRLH1B

GE 04220FL11232A V2.2

GE IS215VPROH2B

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email: 3772179818@qq.com

Email: 3772179818@qq.com Phone: +86 16626708626

Phone: +86 16626708626