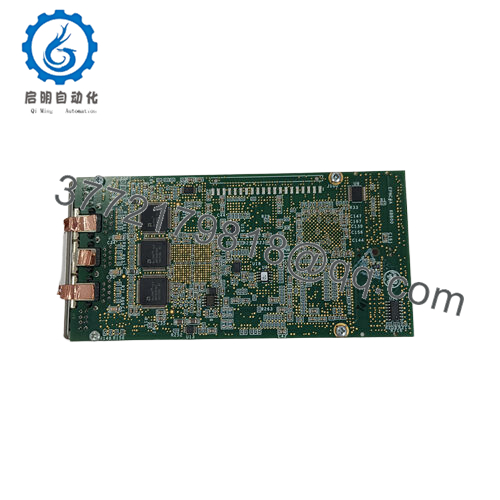

Description

Product Model: IS200EPMCH1

Product Brand: GE (General Electric)

Product Series: Mark VIe / Mark VI Speedtronic family

Product Features (key strengths):

- Distributes control power (28 V DC) and wetting power (24 V/48 V DC) within the Mark VIe PDM cabinet

- Onboard sensing circuits for two AC channels to monitor health of the power feeders

- Fuse protection per output and robust isolation for fault resilience

- Designed for harsh environments; fits in standard control enclosures and supports redundancy schemes

- IS200EPMCH1

Applications & Industry Context

In power plants, gas turbines, and critical industrial installations, the reliability of control systems hinges on clean, stable power to electronics, I/O modules, and sensing circuits. Sudden voltage drops, surges, or wiring faults can confuse control logic, trip systems, or worse, damage sensitive cards. That’s exactly where IS200EPMCH1 comes into play.

Even inside the Mark VIe Speedtronic environment, the IS200EPMCH1 is typically housed in the Power Distribution Module (PDM) cabinet, managing how “wetting” power (used for contact drive) and control power get distributed among I/O packs and internal electronics.

Consider a combined-cycle power plant upgrading to Mark VIe: when they replaced aging power distribution boards with IS200EPMCH1, they saw fewer nuisance trips during transient loads. During cold starts, when auxiliary systems draw high current, the module’s AC sensing circuits detect abnormal channels and protect downstream modules before irreversible harm occurs. In petrochemical or refinery settings, where explosion proofing (Class 1 Zone 2, for example) is required, the board’s segregation of control vs. wetting circuits helps isolate a contact power short from disturbing the delicate logic circuits.

In pharma, cogeneration, or industrial automation setups, the IS200EPMCH1 doesn’t act alone — it becomes the backbone that feeds clean power to analog/digital I/O cards, drives, controllers, and sensors. When all cards in the PDM cabinet depend on stable bus voltages, choosing a power distribution card that resists faults and provides diagnostic feedback is essential. That’s where its role becomes mission critical.

Product Role & System Fit

What exactly is the IS200EPMCH1 in the architecture? It is not a CPU, nor a sensor — it’s a specialized power distribution (jumper) card for the Mark VIe control system. Within the PDM (Power Distribution Module) cabinet, the IS200EPMCH1 receives input power (often 28 V DC or higher via converters) and fans it out to I/O modules, control electronics, and wetting circuits, while also implementing protection and monitoring.

You may sometimes see it described as a “jumper power distribution card” or “JPDG board.” The “jumper” term comes from its role in bridging and distributing power lines (via internal jumpers or connectors) within the PDM structure.

In a typical setup, this module lives alongside PPDA (power / distribution feedback) modules, I/O packs, diagnostic boards, and logic cards. For system integrators, installing the IS200EPMCH1 correctly ensures that every downstream board gets proper voltage sourcing, and that any wiring fault or overload in one branch doesn’t drag down the whole system.

It’s worth noting the compatibility: IS200EPMCH1 is built for the Mark VIe (and often backward-compatible within Mark VI series) control families. It is not a standalone controller — it must reside in a compatible PDM chassis with matching backplane and harnesses.

Technical Features & Benefits

Let’s dig into what sets IS200EPMCH1 apart in a competitive field of power modules.

1. Dual-channel AC sensing and monitoring

Unlike simpler power boards, IS200EPMCH1 includes circuits to sense two separate AC distribution channels. This allows the central controller to monitor the health of external feeders, detect anomalies, and flag them in diagnostics.

2. Segregated wetting vs. control power paths

The board maintains separate paths for “wetting” current (which powers contact closures, solenoids, relays) and for core logic control power. This segregation helps prevent faults in field wiring (contact circuits) from reaching the logic side and causing cascading failures.

3. Protective fuses per output and robust isolation

Every 28 V DC output from the IS200EPMCH1 is individually fused, so a fault in one branch won’t pull down the entire bus. Additionally, internal isolation ensures that noise, surges, or a faulty branch remain contained.

4. Redundancy-friendly architecture

In critical systems, you may deploy redundant PDMs. IS200EPMCH1 is designed so that multiple boards can be daisy-chained using J1, J1X connectors; careful planning ensures that input currents don’t exceed rated thresholds.

5. Industrial robustness in thermal, vibration, EMI environments

The module is designed to operate reliably under industrial conditions, resisting electromagnetic interference, vibration, and temperature swings. Many suppliers cite operational ranges from –40 °C to +70 °C (though local spec sheets should be confirmed)

6. Diagnostic feedback & system integration

Because it monitors AC channels and communicates health data to the main controller, faults can be caught early, logged, and acted upon. Field engineers often rely on that feedback to plan preventative maintenance. This makes the IS200EPMCH1 more than just a passive board — it’s an intelligent distribution hub.

Field anecdote: I once visited a plant where a poor connector on the wetting path caused intermittent undervoltage in a bank of I/O modules. The controller’s diagnostics flagged an AC channel warning (via the IS200EPMCH1), which helped the maintenance crew localize the issue in under an hour — versus chasing wiring across cabinets.

Technical Specifications Table

Here’s an example specification table based on manufacturer and field sources:

| Specification | Typical Value / Range |

|---|---|

| Model | IS200EPMCH1 |

| Manufacturer | GE (General Electric) |

| Series / System | Mark VIe / Mark VI |

| Function | Jumper Power Distribution / Control & Wetting Power Board |

| Input Power | 28 V DC (via converter or DC bus) |

| Wetting Power | 24 V DC or 48 V DC typical (for contact circuits) |

| Protection | Individual fuses per output branch |

| AC Sensing Channels | 2 channels for external AC monitoring |

| Isolation | Internal isolation per branch (varistor, isolation circuits) |

| Operating Temperature | –40 °C to +70 °C (consult supplier data) |

| Mounting | PDM cabinet, vertical board mount via connectors |

| Interface / Connectors | J1, J1X, diagnostic / ribbon connector P2 |

| Typical Output Capacity | Power branch currents per spec (varies per system) |

| Diagnostic Feedback | Monitored health to main controller |

| Redundancy Support | Daisy-chain support for multiple boards |

| Environmental Resistance | EMI tolerance, vibration, industrial durability |

(Note: Always verify actual serial number / revision datasheet for precise figures in your system.)

Related Models

Here are some related GE modules you may encounter in a Mark V / Mark VI / Mark VIe environment (one-line notes on differences):

- IS200EPMCH2 – Similar distribution card with higher current capacity for heavier loads

- IS200EPMDH1 – Dual (redundant) power distribution module for high-availability systems

- IS200EPMCH3 – Version supporting extended temperature ranges for extreme applications

- IS200EPMJH1 – Enhanced variant with digital diagnostics / remote IO monitoring

- IS200EPMCH4 – Compact / simplified distribution card for small PDM setups

- IS200EPMBH1 – Legacy variant compatible with older Mark V architectures

These modules may share form factors or connectors but differ in current ratings, environment resistance, and diagnostics.

WhatsApp: +86 16626708626

WhatsApp: +86 16626708626 Email:

Email:  Phone: +86 16626708626

Phone: +86 16626708626